Heat Curable Conductive Paste

A heat curing, conductive technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] A preferred embodiment of the present invention will be described below. It should be noted that, other than the matters particularly mentioned in this specification (such as the composition of the heat-curable conductive paste), the matters necessary for the implementation of the present invention (such as the production method of the heat-curable conductive paste, the electrode ( The formation method of the conductive film) and the like) can be grasped as a matter of design by those skilled in the art based on the prior art in this field. The present invention can be implemented based on the contents disclosed in this specification and common technical knowledge in this field.

[0049]

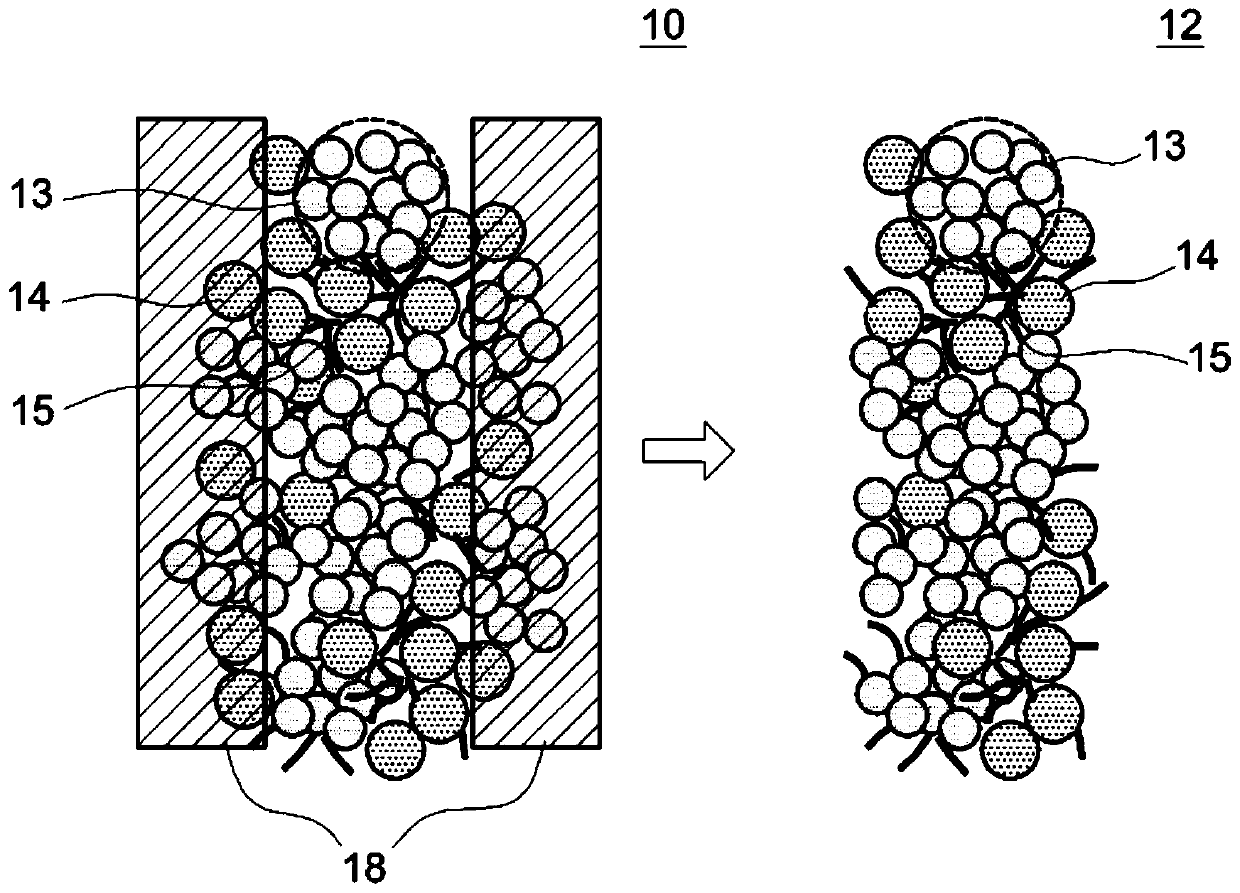

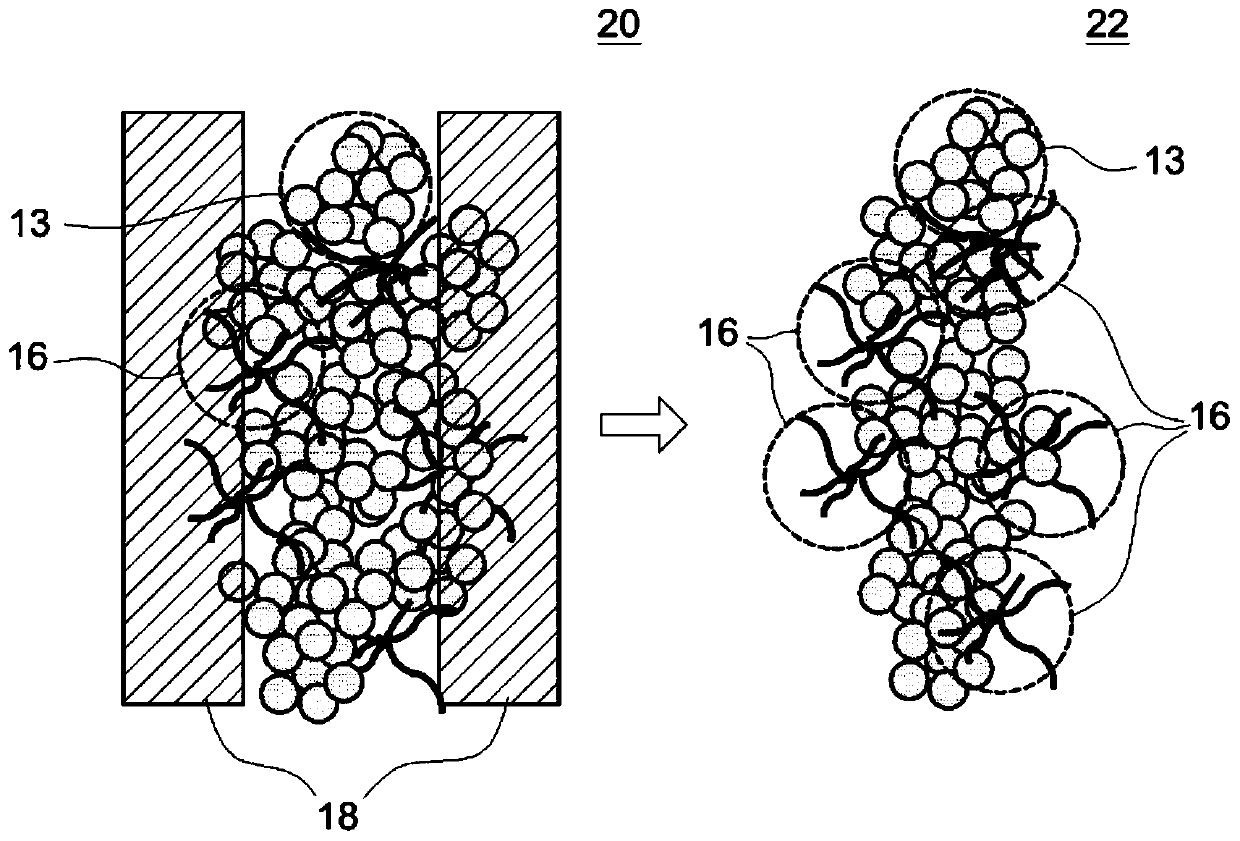

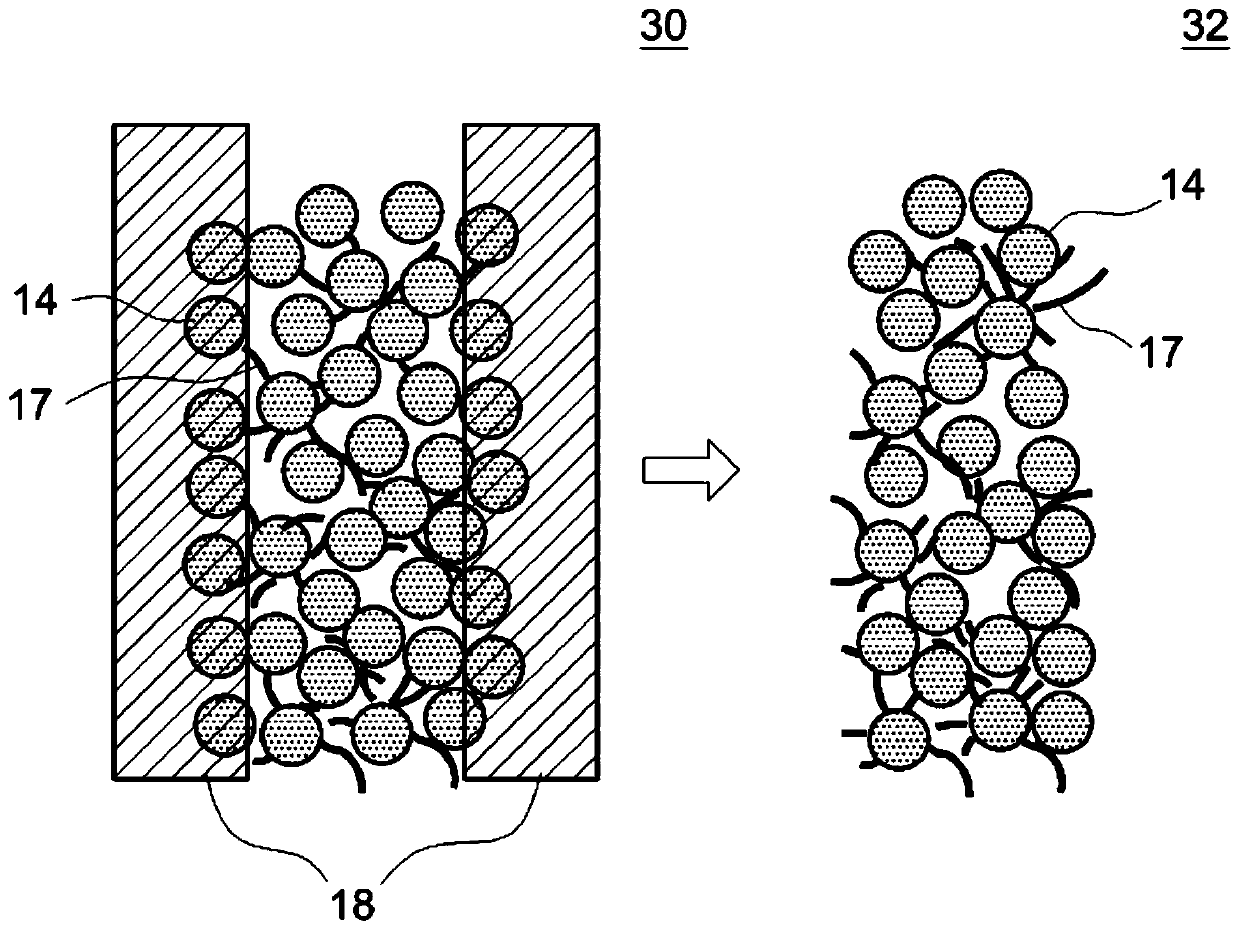

[0050] The heat-curable conductive paste (hereinafter sometimes simply referred to as "paste") disclosed herein contains (A) conductive powder, (B) thermosetting resin, and (C) curing agent as essential components. And it is characterized in that said (A) contains at least two type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com