Method of end sealing for battery

A battery and secondary battery technology, applied to battery components, circuits, electrical components, etc., can solve problems such as unreliability, rivet leakage, hard nylon seals, etc., and achieve the effect of low equipment cost and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

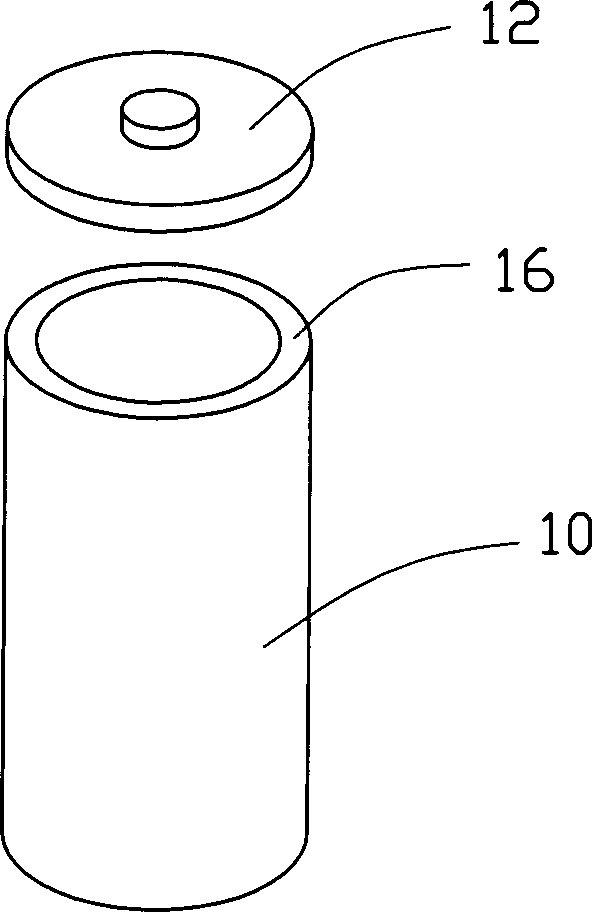

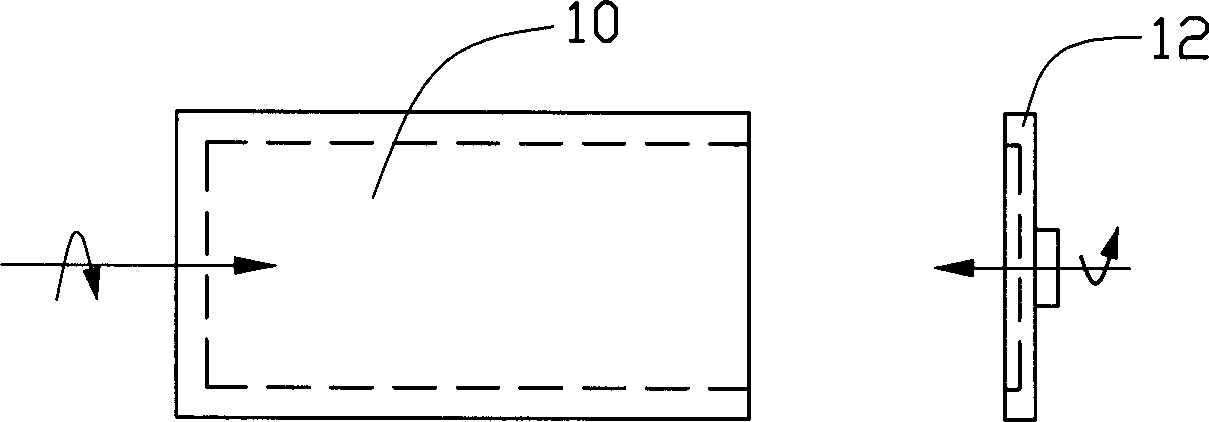

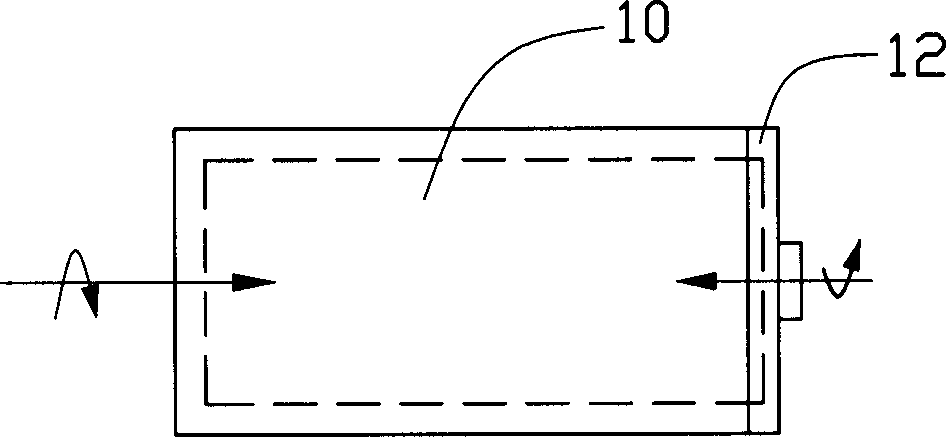

[0016] The general battery production method: First, the electrodes, including positive and negative electrode materials and separators, are wound together and put into the tank body, then the tank body and the upper cover are sealed and welded, and then the electrolyte is injected to seal the liquid injection port. , the liquid injection port is usually sealed mechanically with a small steel ball, that is, the entire preparation process is completed. The present invention improves the process of sealing and welding the tank body and the upper cover. The battery sealing method of the present invention uses friction welding to seal the battery tank body and the upper cover. Friction welding is a solid-state welding method. It uses frictional heat as the heat source. Through mechanical frictional movement and axial pressure, the frictional surface generates heat, and the surface of the workpiece is rotated and heated to a thermoplastic melting state. Or dissimilar metals are fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com