Current lead wire of superconducting device

A technology of current leads and superconducting devices, which is applied in superconducting devices, superconducting/high-conducting conductors, and usage of superconducting elements. problem, achieve the effect of saving space and increasing the heat transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

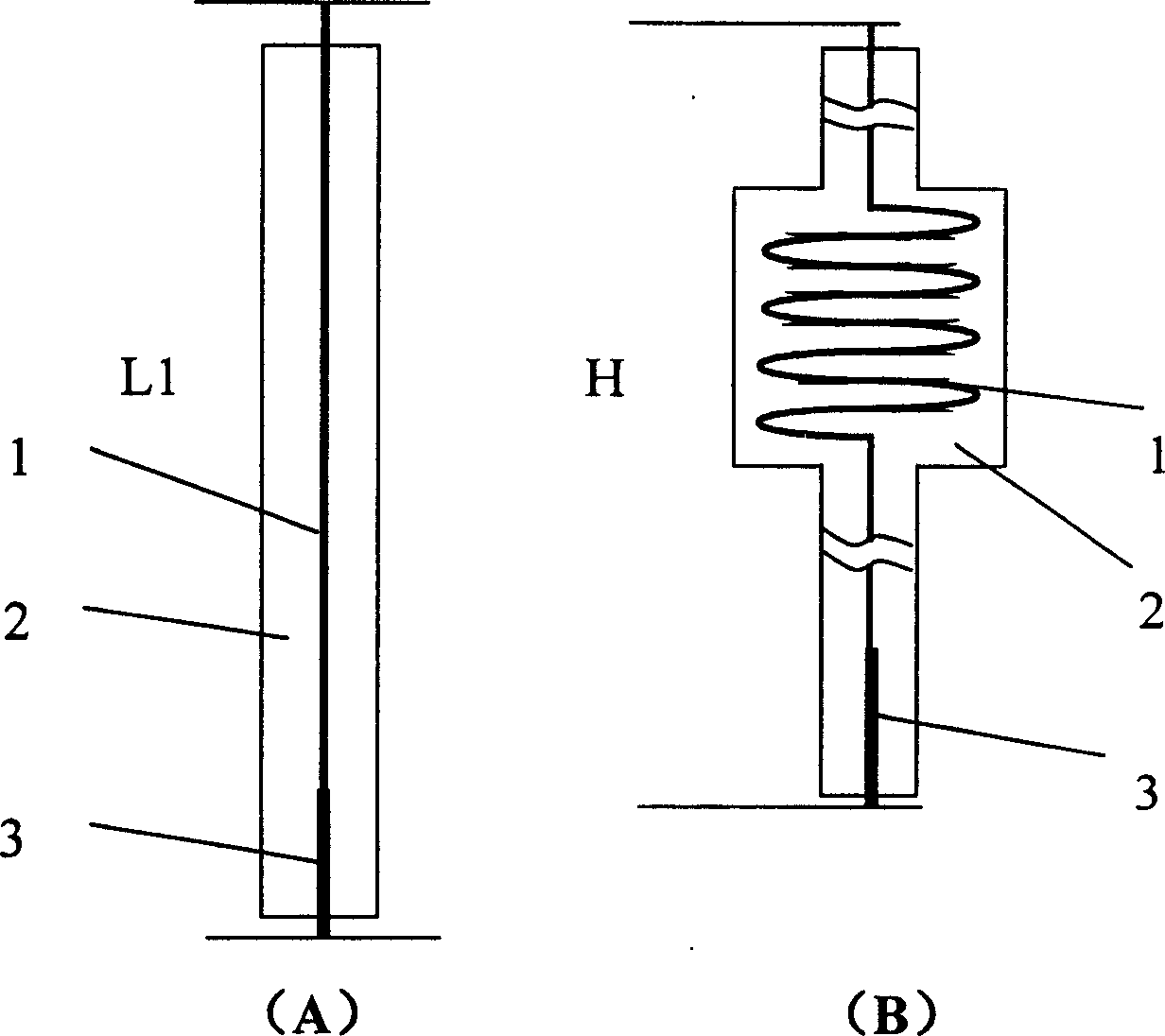

[0015] Embodiment 1: as figure 1 In the high-temperature superconducting device, a current lead wire with a current of 400A current is provided. The diameter of the copper rod 1 is 12mm. For the same heat transfer path (copper rod length) 1200mm, if a straight rod type is used, the required space The height is 1200mm; if a part of the lead wire adopts the solenoid type, the diameter of the solenoid is 60mm, and the pitch is 20mm, the required space height is only 460mm.

Embodiment 2

[0016] Embodiment 2: as figure 2 , assuming a binary current lead of a low-temperature superconducting device working at 20K with a current of 100A, adopts the operation mode of two-stage refrigeration, the length of the superconducting material 3Bi2212 rod with a diameter of 16mm is 225mm, and a copper rod with a diameter of 6mm The length of material 1 is 1320mm, and the temperature of the joint between copper rod 1 and superconducting material 3 is fixed at 70K. For the same heat transfer path (copper rod length) of 1320mm, if a straight rod type is used, the required space height is 1545mm; if The copper rod part of the lead wire adopts a solenoid type. The diameter of the solenoid is 45mm, the pitch is 16mm, and the required space height is 437mm if it is wound 8 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com