In-line moniting controlling system of blast furnace coal powder injection

A monitoring control and blast furnace coal injection technology, applied in the field of blast furnace coal injection system, can solve the problems of large influence, low sensitivity, and inability to clear and block coal injection branch pipes, and achieve the effects of simple configuration, high sensitivity and reliable monitoring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

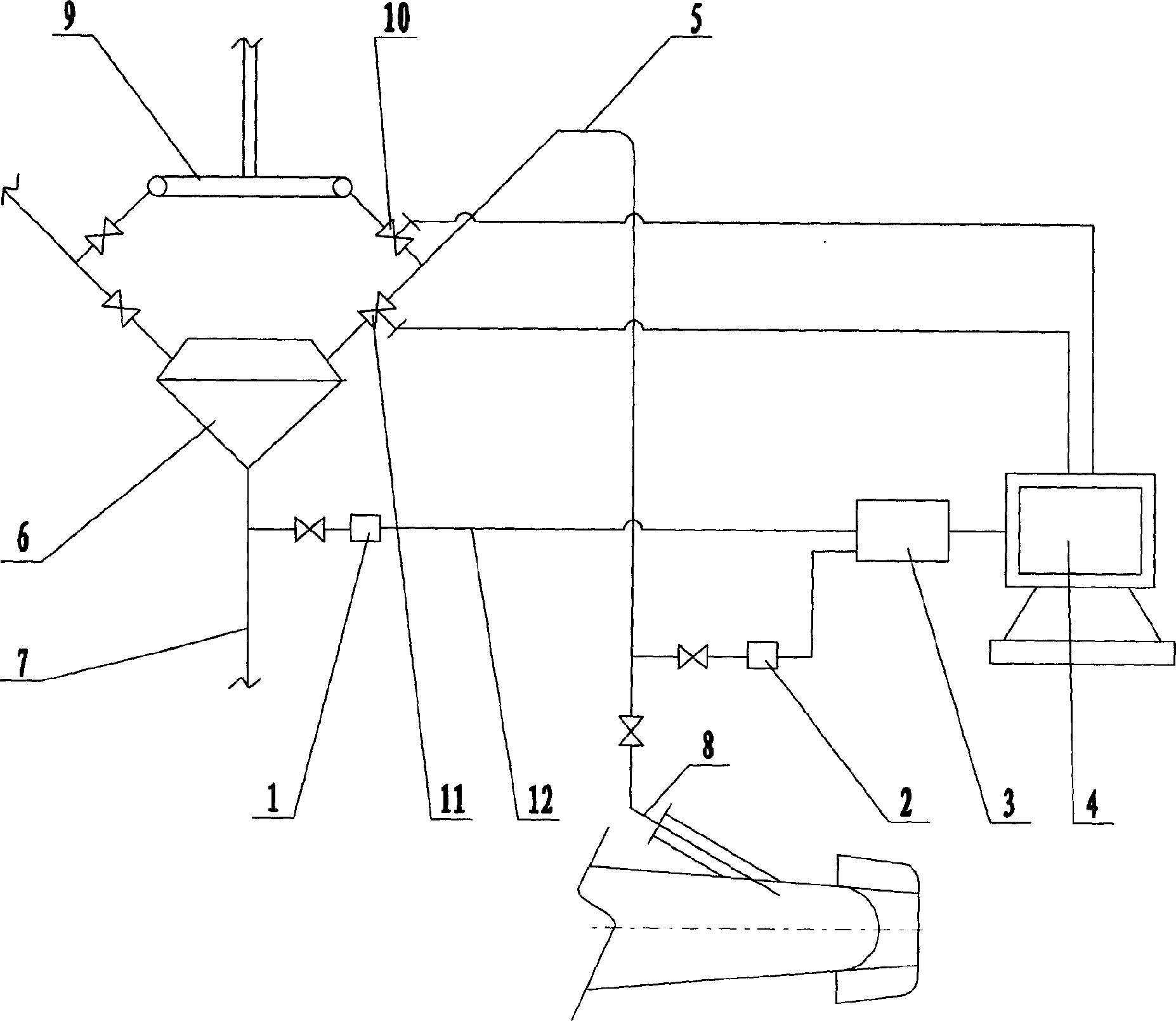

[0010] exist figure 1 In the process, the pulverized coal is sprayed into the blast furnace through the coal injection main pipe 7, the pulverized coal distributor 6, the coal injection branch pipe 5 and the spray gun 8. Set a pressure detection point on the coal injection main pipe 7 before the pulverized coal distributor 6, install the coal injection main pipe pressure transmitter 1, set a pressure detection point on the coal injection branch pipe 5 before the spray gun 8, and install the coal injection branch pressure The transmitter 2 and the transmission wire 12 transmit the pressure detection signal to the I / O module 3 , and the I / O module 3 is connected to the PLC 4 . The electric cut-off valve 11 of the coal injection branch pipe is installed on the coal injection branch pipe 5 at the outlet of the coal powder distributor 6, and the purge solenoid valve 10 is installed on the connecting pipe between the nitrogen purge ring pipe 9 and the coal injection branch pipe 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com