Waterproof sealing compound for asphalt road surface, production and applied constructing process

A technology of asphalt pavement and curing agent, which is applied to asphalt coatings, roads, roads, etc., and can solve problems such as high construction costs, poor durability, and immature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

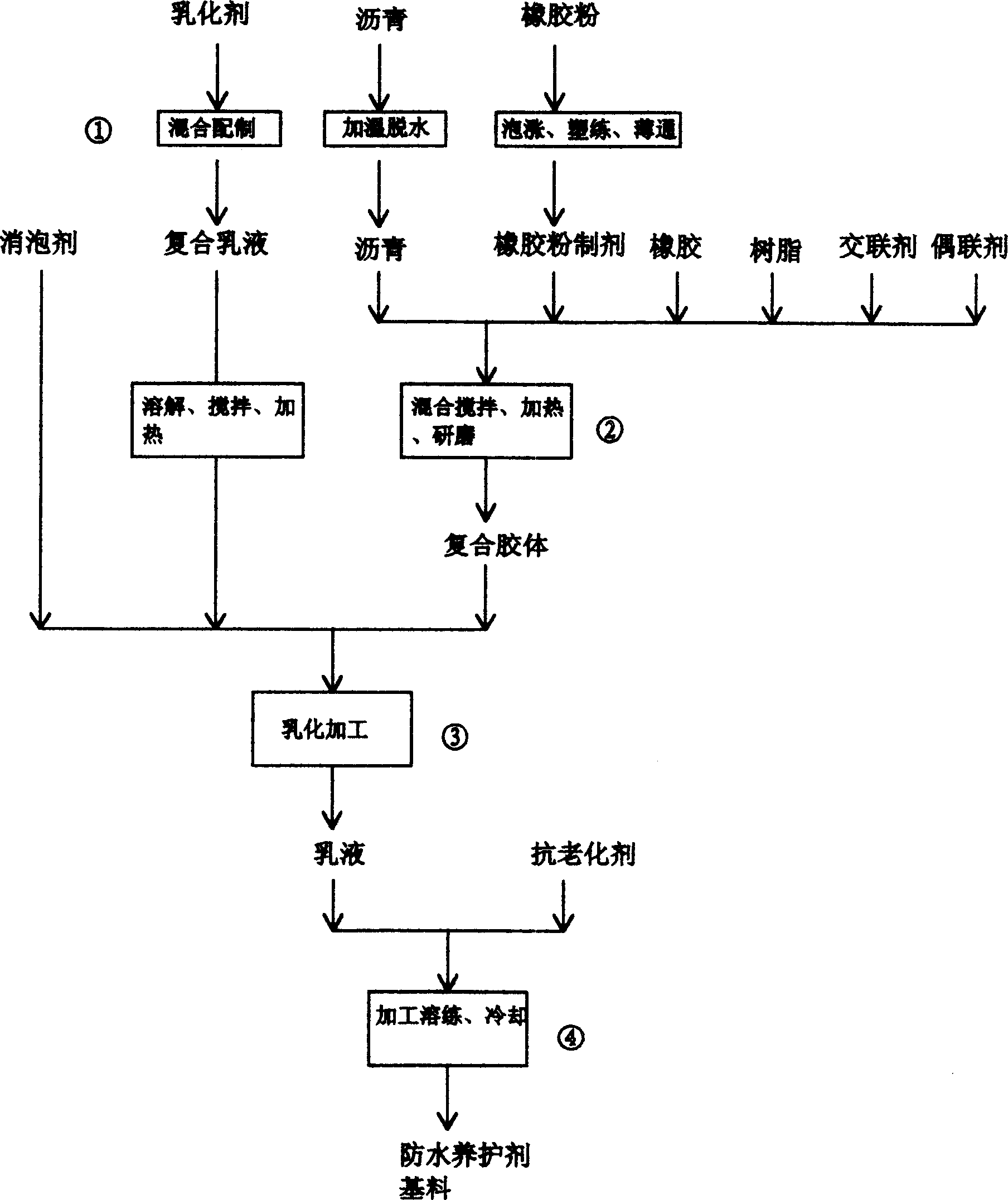

[0081] Embodiment one, the production example of asphalt pavement waterproof curing agent:

[0082] 1. Raw material ratio (weight ratio):

[0083] asphalt 100

[0084] Rubber powder 12

[0085] Resin 3

[0086] rubber 3

[0087] Crosslinker 8

[0088] Coupling agent 1.5

[0089] Emulsifier (compound) 4.5

[0090] Anti-Aging Agent 8

[0091] Water 142 (add in two times, leave 20 to add during construction)

[0092] Defoamer trace

[0093] The production process is attached figure 1 As shown, the specific control indicators are as mentioned above and will not be repeated here.

[0094] 2. The product performance is as follows:

[0095] Adhesion: >1.2Mpa;

[0096] Waterproof performance: impervious to water for 3 minutes under normal pressure;

[0097] Penetration depth: 10~20mm;

[0098] Tack-free time: 2 hours.

[0099] 3. Application features:

[0100] ①The construction process is the same as before, add 0.2% foaming agent and 20% activator during construction...

Embodiment 2 Embodiment 1 application example

[0103] 1. Raw material ratio (weight ratio):

[0104] Asphalt pavement protective agent base material 100 (formula and processing technology are the same as Example 1)

[0105] Foaming agent 0.5

[0106] Water 8~15

[0107] cement 4

[0108] Construction process:

[0109] First pour the foaming agent, cement and water into the protective agent base material and stir evenly, then spray. Within 15 minutes after spraying on the road, push and knead with a foam generator, and the curing agent will immediately turn into foam. After 15 minutes, the foam will Disappeared, 6 hours later, it can be opened to traffic. Generally, it is applied in two layers, the first layer is thinner and the second layer is thicker.

[0110] 2. The main performance indicators are as follows:

[0111] Adhesion: >1.2MPa;

[0112] Waterproof performance: impervious to water for 3 minutes under normal pressure;

[0113] Penetration depth: 10~20mm;

[0114] Tack-free time: 2 hours.

[0115] 3. Appl...

Embodiment 3

[0118] Embodiment three: the application example of using the asphalt pavement waterproofing and curing agent of embodiment one to treat serious diseased asphalt pavement:

[0119] 1. The material formula (weight ratio) used for the treatment of severe pavement diseases:

[0120] Protective agent base material 100 (formula and processing technology are the same as Example 1)

[0121] cement 8

[0122] Rubber powder (<200 mesh) 10

[0123] 2. Construction process: put the above three materials into the curing agent in proportion, stir evenly, manually paint on the serious road surface disease (a large number of cracks, network cracks), push and knead with a foam generator, and then use high pressure blown by blower

[0124] 3. Its main performance indicators are as follows:

[0125] Adhesion: >1.2Mpa;

[0126] Waterproof performance: impervious to water for 3 minutes under normal pressure;

[0127] Penetration depth: 10~20mm;

[0128] Tack-free time: 2 hours.

[0129] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com