Epoxy composition for light semiconductor packing

A technology of optical semiconductor and epoxy resin, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of poor heat resistance, reliability of optical semiconductor components, high moisture absorption rate, etc., and achieve high durability Ultraviolet light, excellent light transmittance, low moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Each component used in embodiment and comparative example is described in detail as follows:

[0073] Epoxy resin a: Produced by Changchun Artificial Resin Factory, the bisphenol A polyglycidyl ether sold under the trade name BE-501 has an epoxy equivalent weight (EEW) of about 500g / eq.

[0074] epoxy resin b : The polyglycidyl ether of the cresol-aldehyde condensate produced by Changchun Artificial Resin Factory and sold under the trade name CNE 200ELA, its epoxy equivalent is between about 200 to 220g / eq, and the hydrolyzable chlorine is below 200ppm.

[0075] epoxy resin c : The triglycidyl ether of isocyanurate sold under the trade name TEPIC produced by Nissan Chemical Co., Ltd., has an epoxy equivalent of about 100 g / eq.

[0076] hardener : Hexahydrophthalic anhydride sold under the trade name HHPA produced by Nippon Chemical Institute, has an acid content of about 154 g / eq.

[0077] hardening accelerator : 2-methylimidazole.

[0078] Antioxidants : 2...

Synthetic example 1-

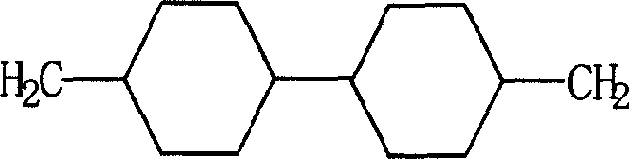

[0079] Synthesis example 1- Epoxy resin d (the epoxy resin of formula (1) of the present invention)

[0080] In a stainless steel autoclave with electromagnetic stirring, put 40 grams of epoxy resin b (CNE-200ELA, EEW=200, manufactured by Changchun Artificial Resin Factory Co., Ltd.), 120 grams of THF, and a commercially available 5wt% Ru-C catalyst 0.6 g, the reaction kettle was sealed, and hydrogen gas was introduced to make the pressure 5.0 MPa, the reaction temperature was controlled at 60°C, and the reaction time was 8 hours. After the reaction is finished, the catalyst is filtered, and the solvent is evaporated in a vacuum at 150° C. to obtain the aromatic ring hydrogenated epoxy resin (epoxy resin d) of the structure of formula (1), the hydrogenation rate of benzene nucleus is 84.8%, EEW=263 , Epoxy group loss rate = 24%.

Embodiment 1-6 and comparative example 1-3

[0082] According to the ingredients and amounts (% by weight) shown in Table 1 below, each ingredient was fully mixed with a stirrer, and then fully kneaded by a twin-shaft roller under the condition of 85°C. After cooling, it is pulverized to obtain an epoxy resin composition for semiconductor encapsulation.

[0083] Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Comparative example 1

Comparative example 2

Comparative example 3

Epoxy resin a

15

15

46

75

30

20

epoxy resin b

15

epoxy resin c

15

15

15

epoxy resin d

55

40

40

40

25

20

10

55

hardener

44.5

44.5

44.5

44.5

44.5

33.5

24.5

44.5

24.5

hardening accelerator

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

Antioxidants

0.4

0.4

0.4

0.4

0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com