Header for use in heat exchangers, heat exchanger and method for manufacturing the same

A technology for heat exchangers and heat exchange tubes, applied in the field of headers, can solve the problems of increasing the number of processing steps, cumbersome machining, and increasing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

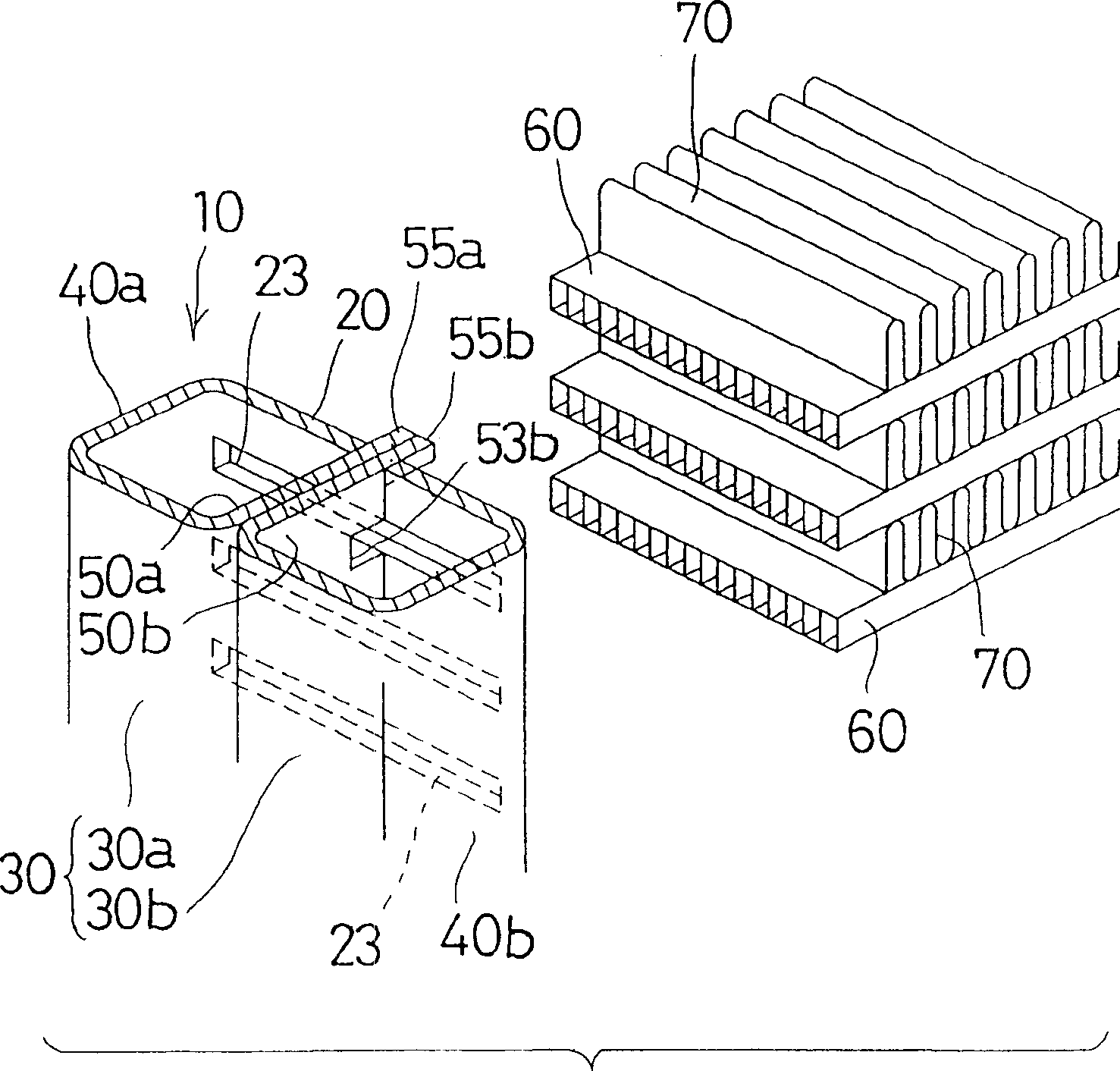

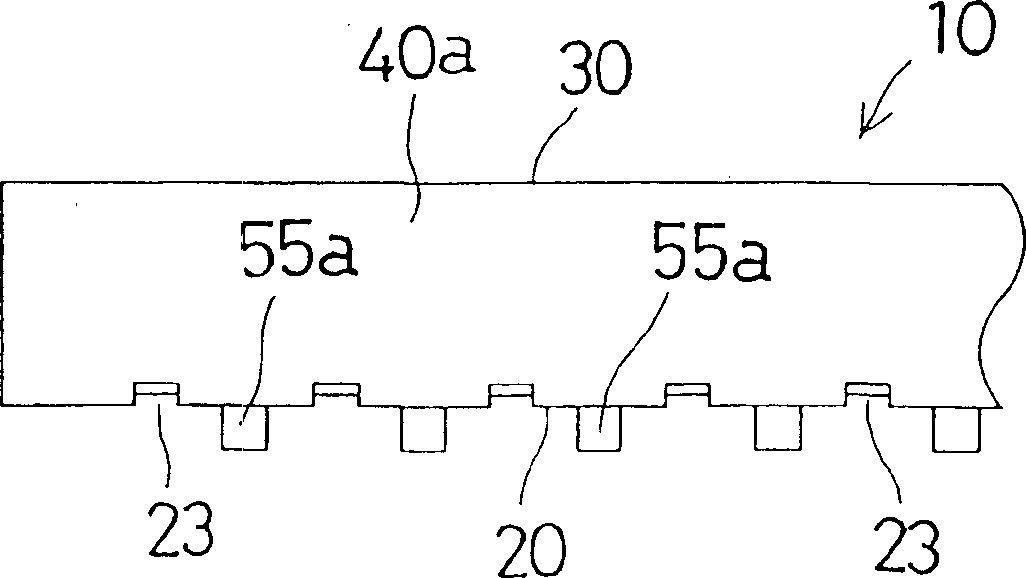

[0151] figure 1 6 to 6 show a header 10 applied to a heat exchanger according to a first embodiment of the present invention. As shown in these figures, the manifold 10 includes a strip-shaped base wall 20, an opposing wall 30 opposite to the base wall 20, a pair of side walls 40a and 40b, and a pair of reinforcing walls 50a and 50b disposed at a laterally central position between the base wall 20 and the opposite wall 30 and extending along the longitudinal direction of the header 10.

[0152] As shown in FIGS. 7 and 8, the header 10 is an integrally formed object obtained by bending a press-formed plate 11 having a predetermined shape formed by die-cutting press-forming. Specifically, the press-formed sheet 11 is a wide strip-shaped sheet. In the transverse central region of the plate 11 , the plate 11 has a base wall region 21 extending in the longitudinal direction of the plate 11 . This base wall region 21 will constitute the above-mentioned base wall 20 . On both si...

no. 2 example

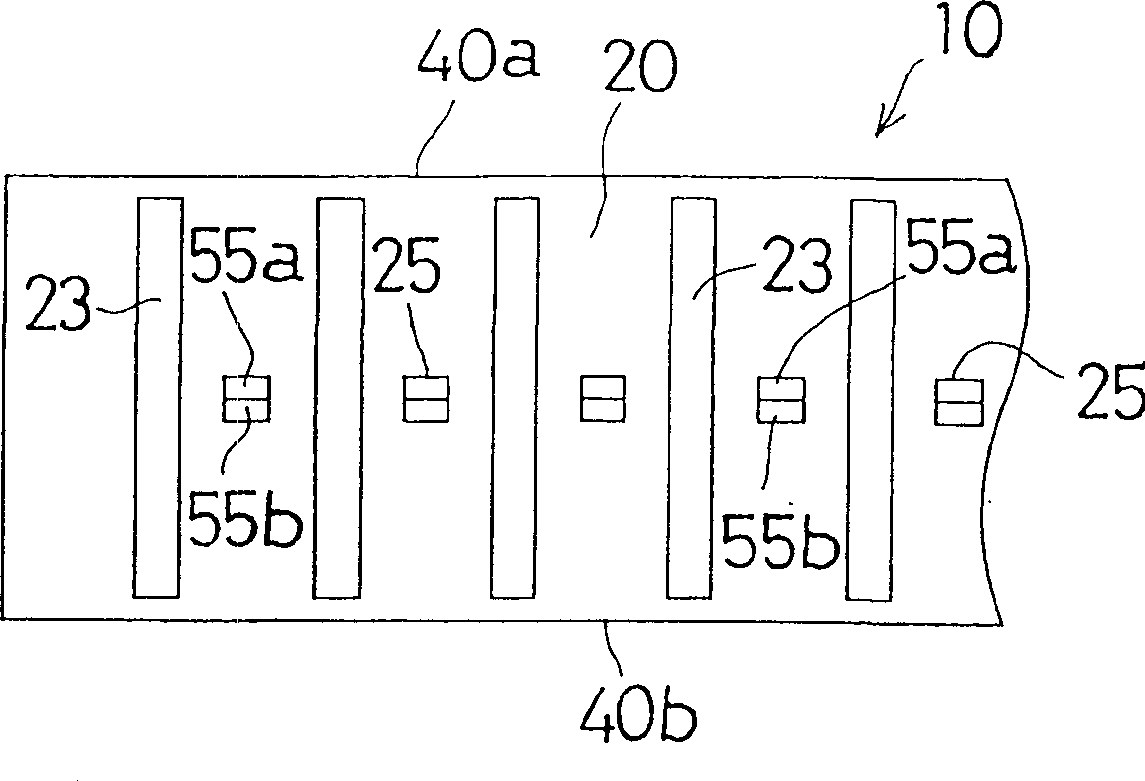

[0172] Figures 9 to 13 A header 10 for use in a heat exchanger according to a second embodiment of the invention is shown. As shown in these figures, in the same manner as the first embodiment, the press-formed plate 11 constituting the header 10 has a base wall region 21, side wall regions 41a and 41b, a first half opposing wall region 31a, a second Two halves of opposing wall regions 31b and first and second reinforcing wall regions 51a and 51b. On the base wall region 21, cannula openings 23 are provided at intervals.

[0173] Further, in the press-formed panel 11 , at the side edges of the first and second reinforcing wall regions 51 a and 51 b , insertion flanges 55 a and 55 b are alternately formed in the longitudinal direction of the panel 11 . Further, between the adjacent cannula openings 23 in the base wall region 21, first insertion flange engaging openings 25a and second insertion flange engaging openings corresponding to the insertion flanges 55a and 55b are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com