Apparatus for rotating and drawing of crystal with damping

A pulling device and crystal technology, applied in the direction of crystal growth, self-melting liquid pulling method, single crystal growth, etc., can solve the problems of increased production and equipment maintenance costs, crystal cracking or broken, loss, etc., to protect the seed crystal Rod, the effect of ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

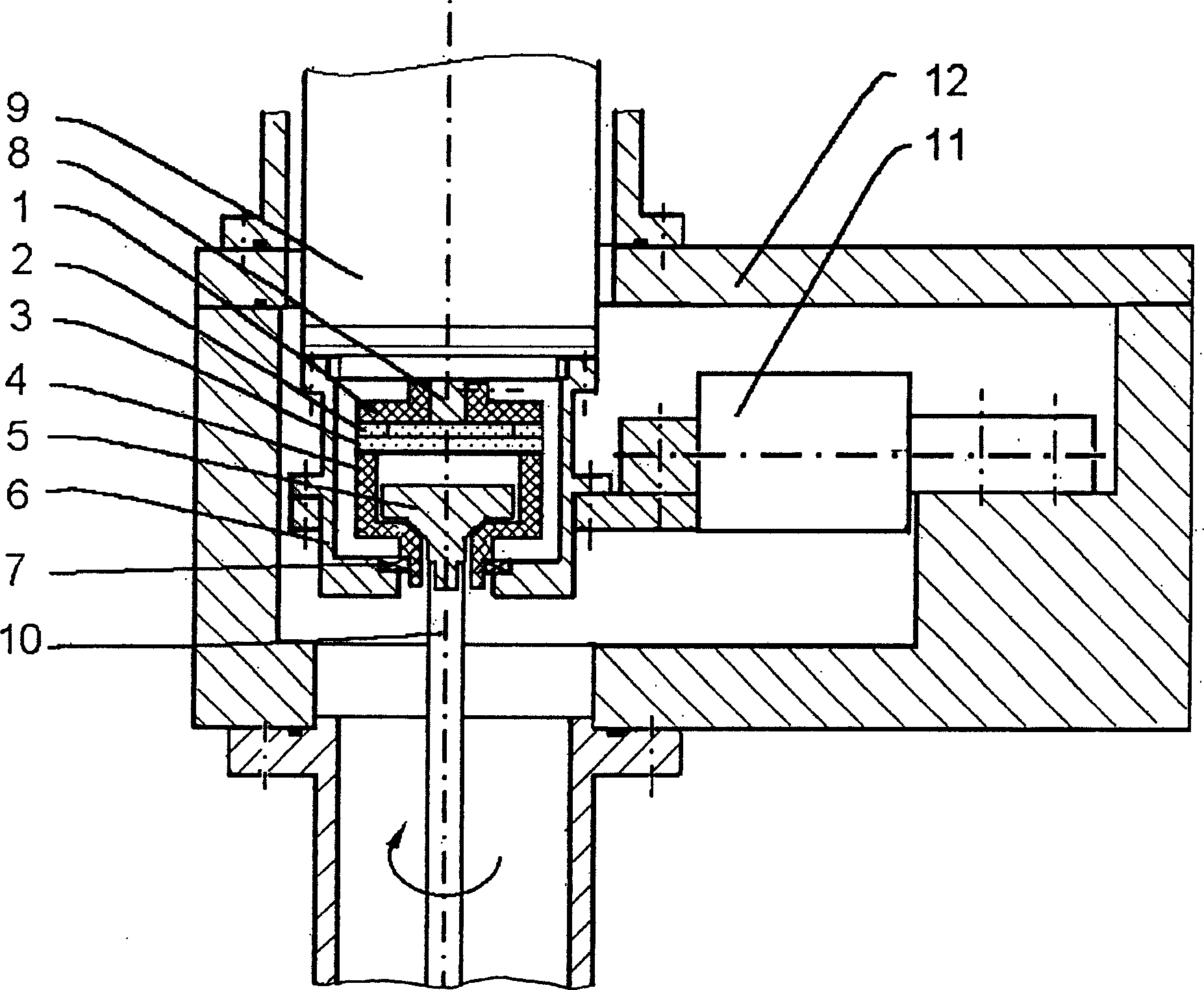

[0010] The present invention is mainly composed of a flange 1, a flexible disc 2, a conical turntable 4, a friction cone 5, a seed rod 10, a support shell 6 and a motor 9, the flange 1 is made of nylon, and is connected with the motor shaft 8 Together, a flexible disk 2 is fixed on the lower end surface of the flange 1, and the conical turntable 4 is also made of nylon, and a flexible disk 3 is fixed on its upper end surface, and a certain pressure is maintained between the two disks (for During the rotation of the motor, the rotational energy is transmitted by the damping effect between the two flexible discs), the materials of which are made of polymer porous material or rough surface flexible material, and are respectively fixed on the flange plate 1 by three circumferentially symmetrical steel needles. And on the conical turntable 4. The friction cone 5 is made of brass, and is arranged on the conical surface of the conical turntable 4. The lower end of the friction cone 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com