Production method of ceramic polished brick and ceramic polished brick produced by it

A technology of ceramic polished tiles and a production method, applied in the field of ceramic polished tiles, can solve the problems of easy deformation, complicated process, poor wear resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

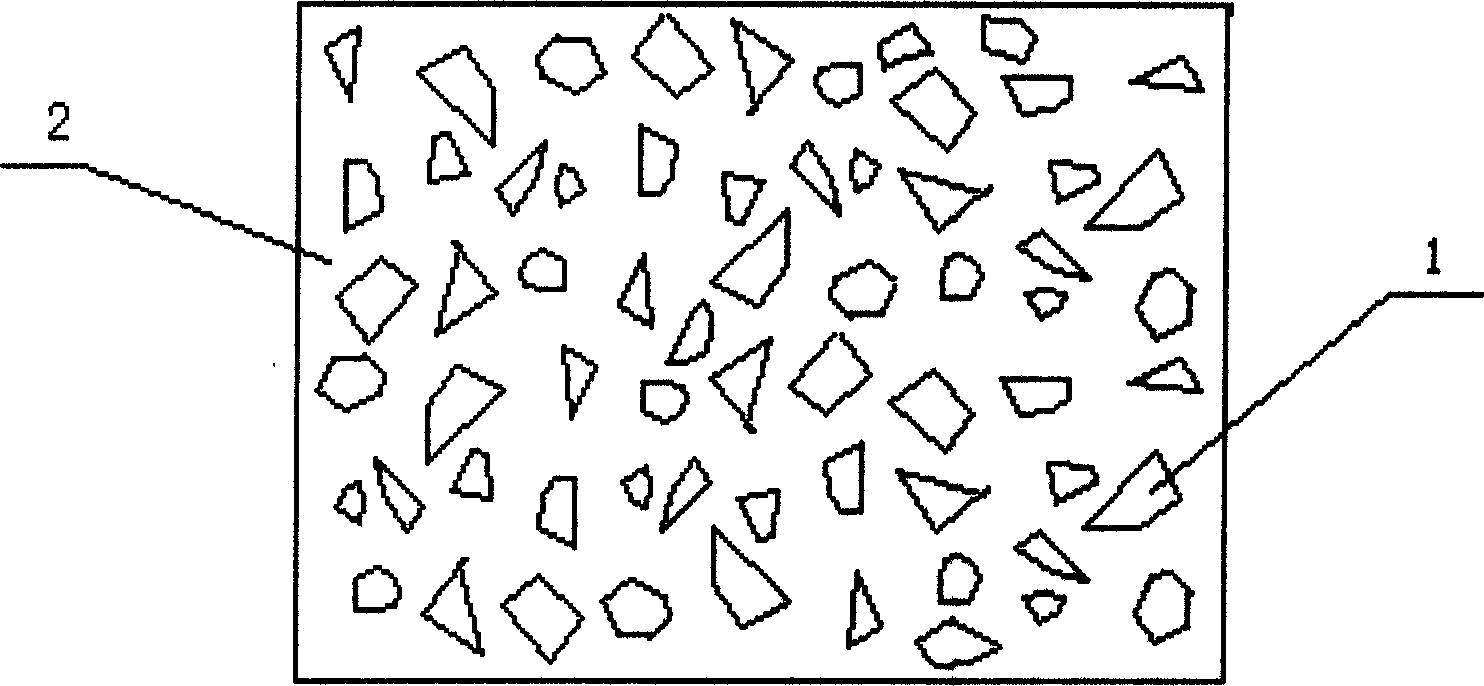

[0015] According to the existing production technology of ceramic polished tiles, the preparation, molding, firing and polishing of molding materials are carried out as follows: the silicate mineral raw materials and auxiliary raw materials commonly used for ceramic polished tiles including clay, feldspar, quartz, talc, etc. are used, according to The conventional production method of polished brick blanks prepares spray powder A, grinds spray powder A into a block, and then crushes and sieves to obtain ceramic molding particles with a particle size of 0.65mm-1.4mm——granule B; On the basis of the formula of powder A, add the opacifying agent zirconium silicate ZrSiO of 4% by weight 4, prepare the spray powder C by the conventional production method of the polished brick blank, then use the mill to grind the spray powder C to obtain the micropowder D, the content of the fine powder with a particle size less than 0.125mm in the micropowder D is 50% by weight, and then The granul...

example 2

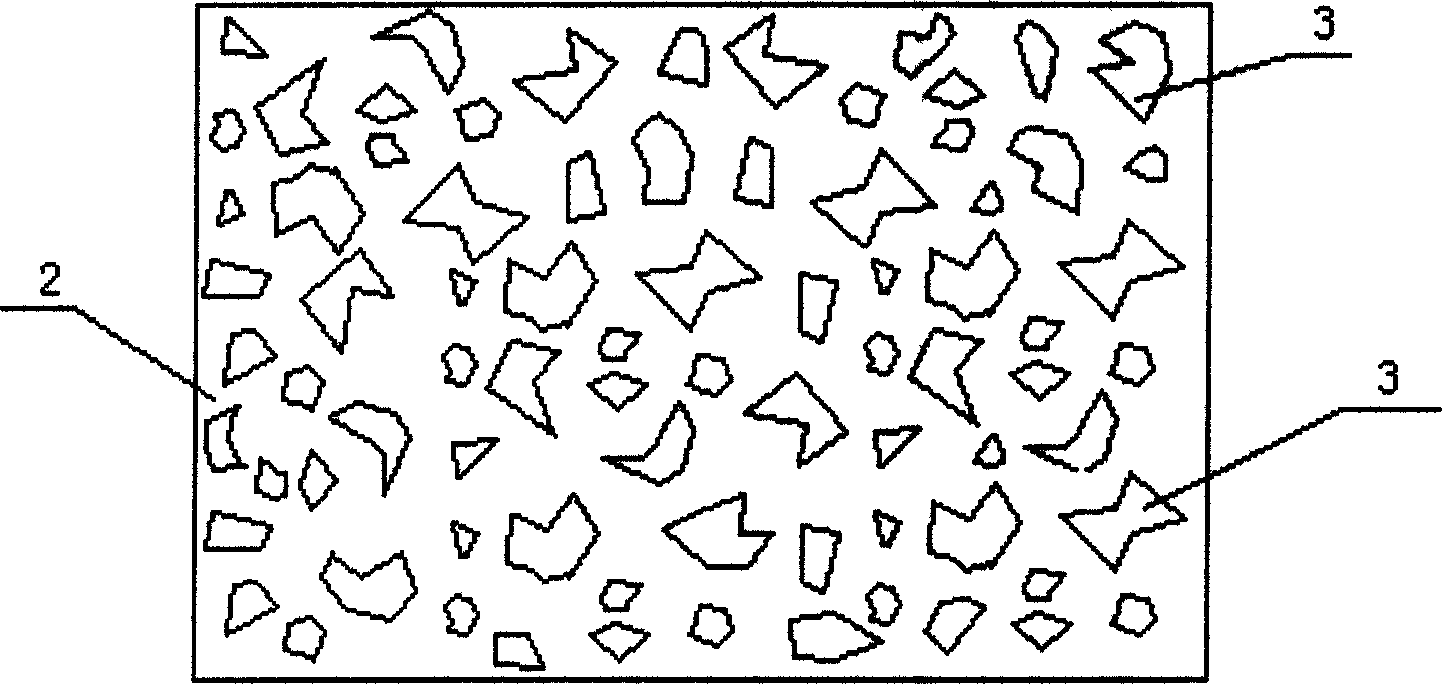

[0017] According to the method in Example 1, the spray powder C in Example 1 is prepared into a granular material with a particle size of 1mm-2.5mm or a granular material with a particle size of 1.5mm-5mm, and the spray powder A in Example 1 is ground Prepare the micropowder whose particle size is less than 0.125mm and the fine powder content is 40%-60% by weight, and mix uniformly according to the ratio of granular material: micropowder as 7:3 or 3:7 to obtain a fine powder mixture, the fine powder mixture Among them, the weight percent of fine powder is 12%-18%, and the weight percent of granule is 70%, or the weight percent of fine powder is 28%-42%, and the weight percent of granule is 30%, again according to example 1 Method Compression molding, firing, polishing, the particles presented on the brick surface are less transparent and lighter in color than the fine powder fired products wrapped around it, and the particles with a particle size of 0.8mm-2.5mm or 0.8mm-5mm are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com