Control device and method for raising injection moulding machine production efficiency using application frequency changer

A technology of production efficiency and control method, applied in the direction of DC motor speed/torque control, control system, electrical components, etc., can solve the problems of short working cycle time of injection molding machine, increased production cycle time of injection molding machine, and reduced production efficiency , to achieve the effect of ensuring rapid response capability, ensuring process requirements and production efficiency, and eliminating production efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

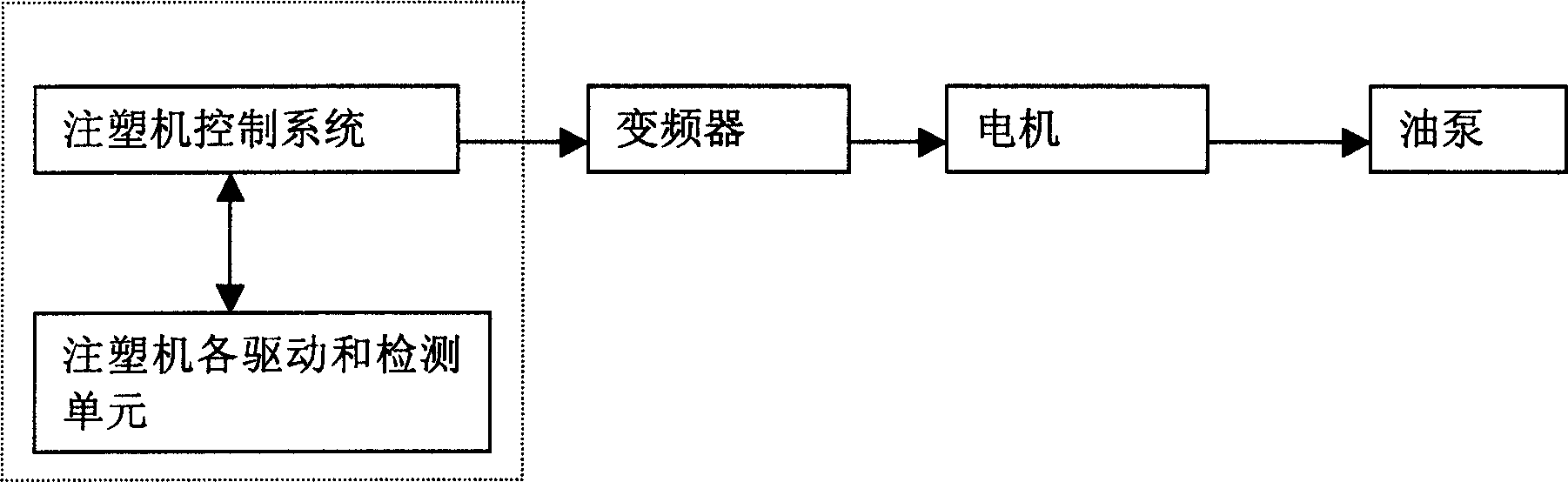

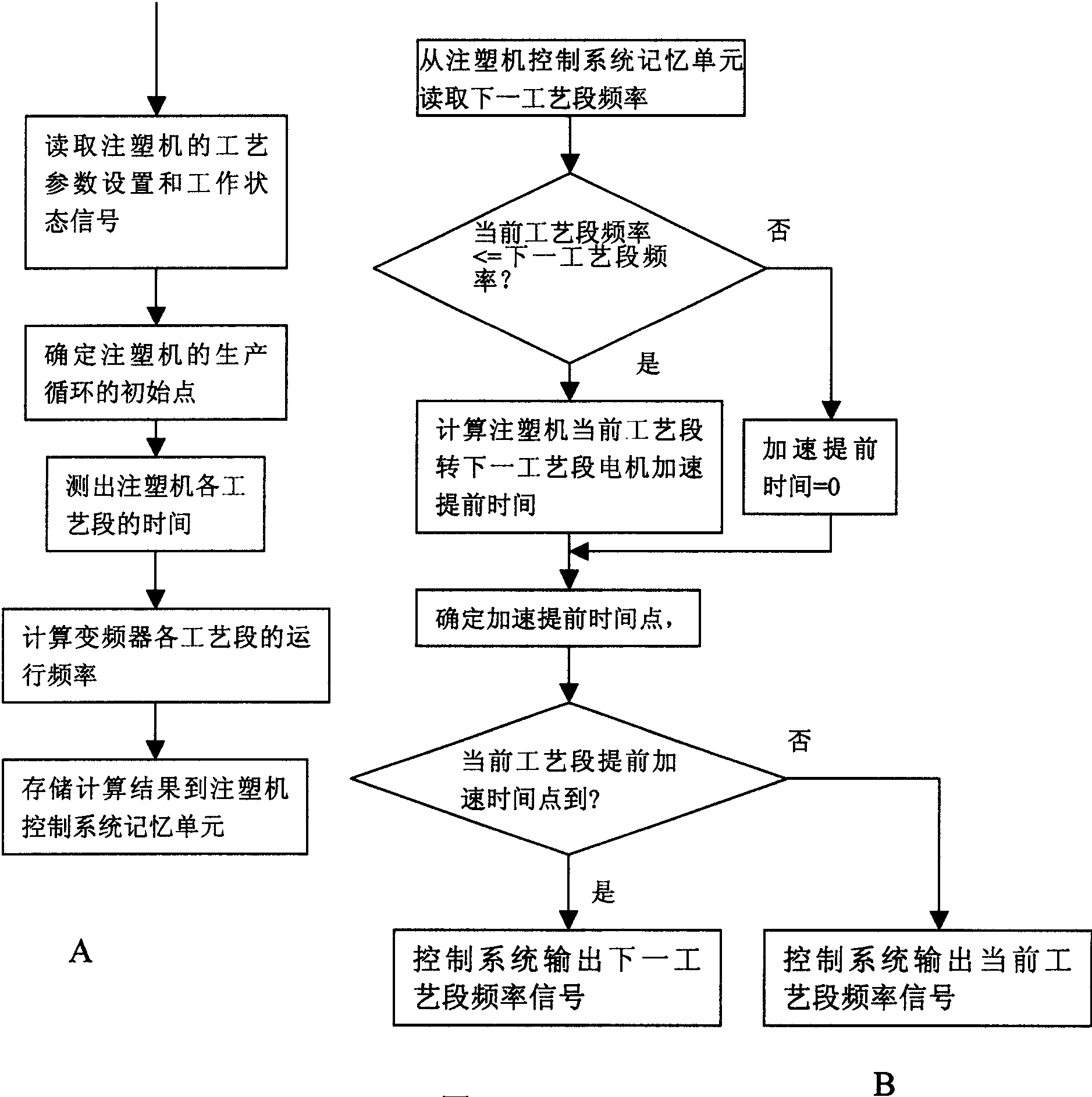

[0034] With reference to accompanying drawing, the basic structure that the present invention implements is to adopt figure 1 As shown in the connection, the remaining parts are the same as the existing injection molding machine, and will not be described in detail here.

[0035] from figure 1 It can be seen from the figure that the control system of the injection molding machine is connected to the frequency converter and processes the signals input by the drive and detection units of the injection molding machine. These signals include the pressure and flow setting parameters related to the injection molding process, as well as the position, time, limit Bit switch and the current process section flag, as well as the operating parameters of the inverter.

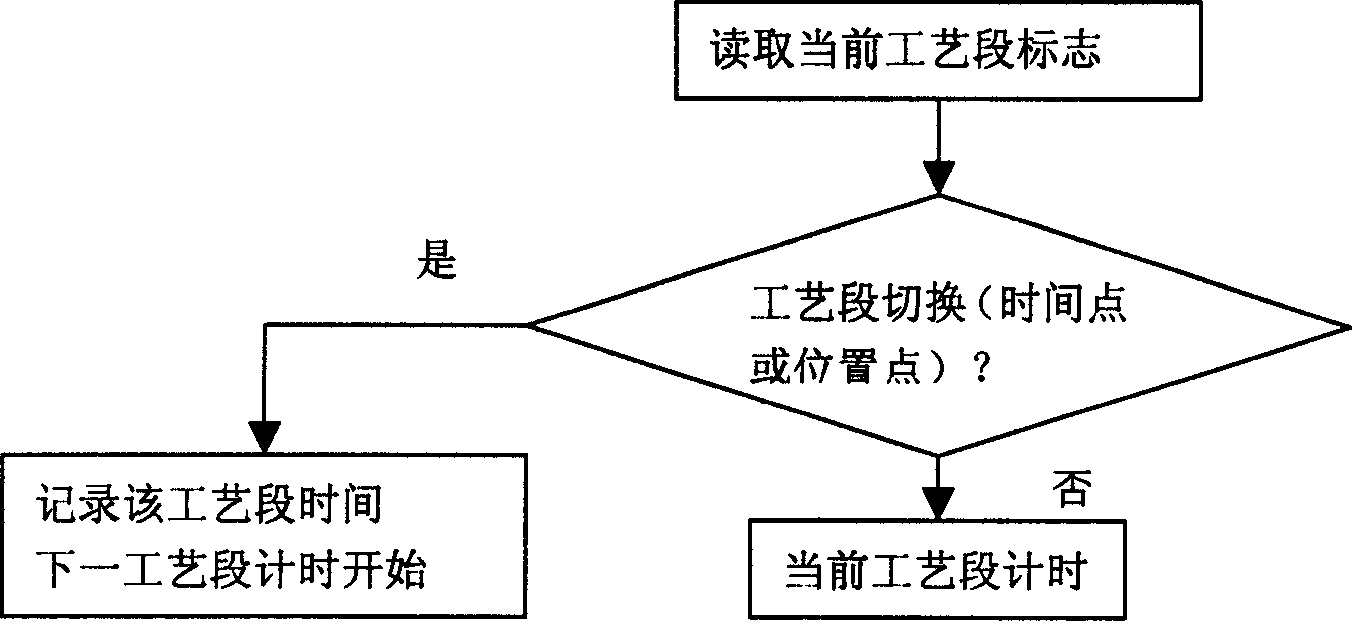

[0036] Signal detection and processing includes:

[0037] The inverter is connected to the motor and the oil pump. The operating frequency of the motor in different process sections is not completely consistent. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com