Control device and mothod for raising injection moulding machine production efficiency based on energy-saving frequency change speed regulator

A frequency conversion speed regulator and production efficiency technology, applied in the field of injection molding machines, can solve the problems of short cycle time of injection molding machines, reduced production efficiency, increase of production cycle time of injection molding machines, etc., to ensure process requirements and production efficiency, eliminate The effect of reducing production efficiency and ensuring rapid response capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

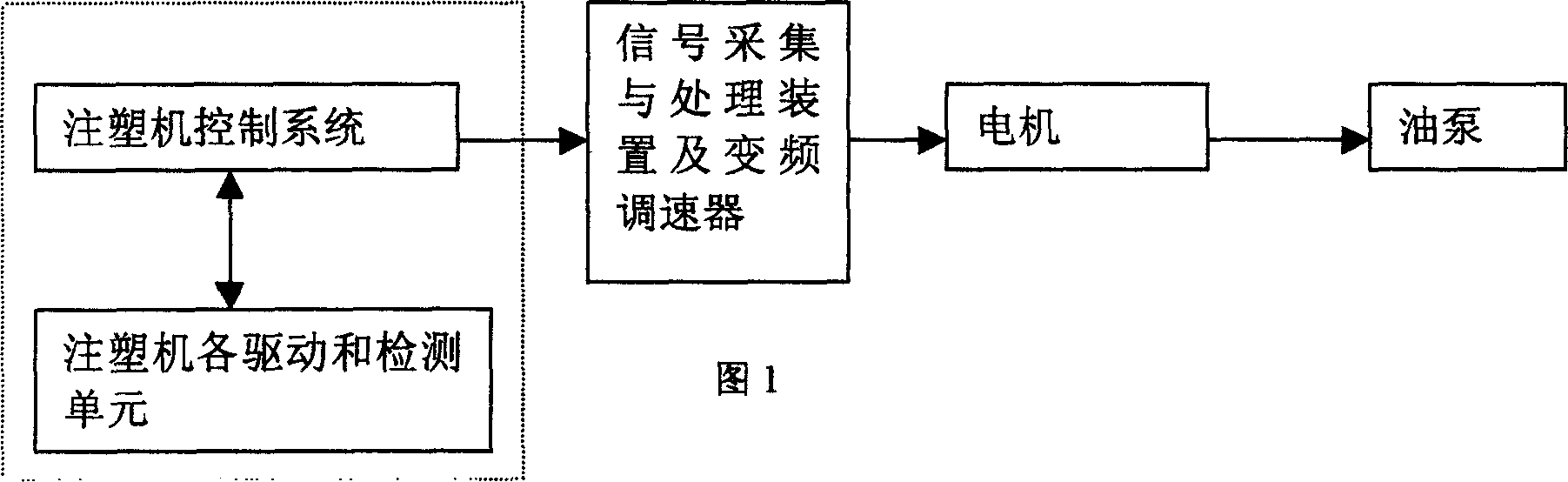

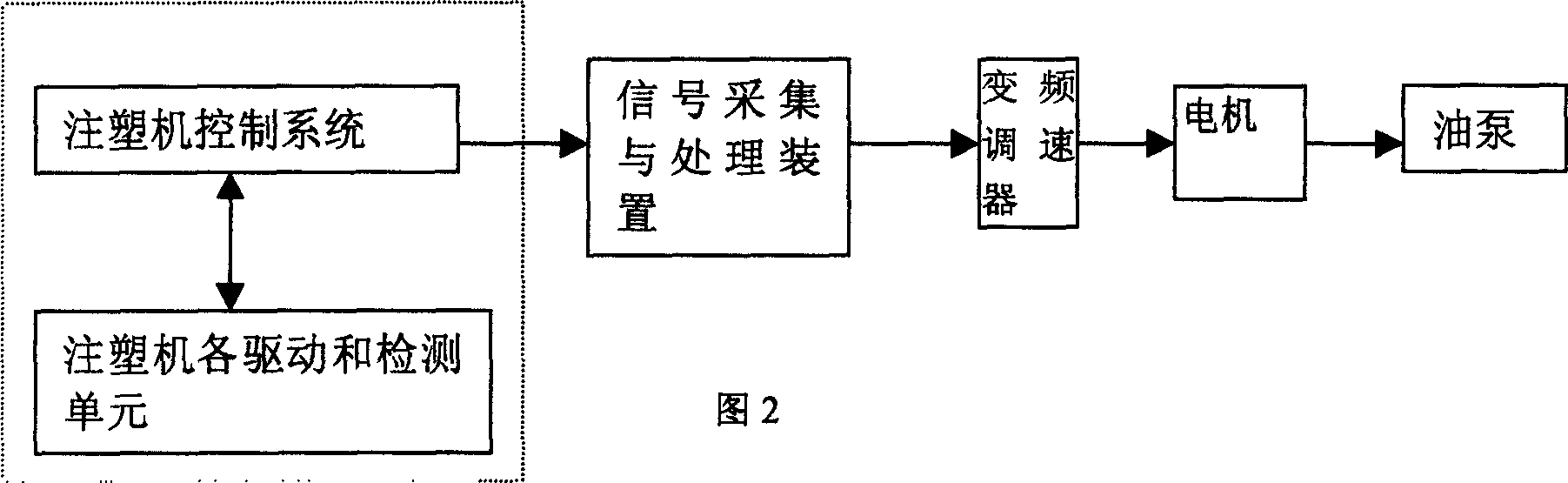

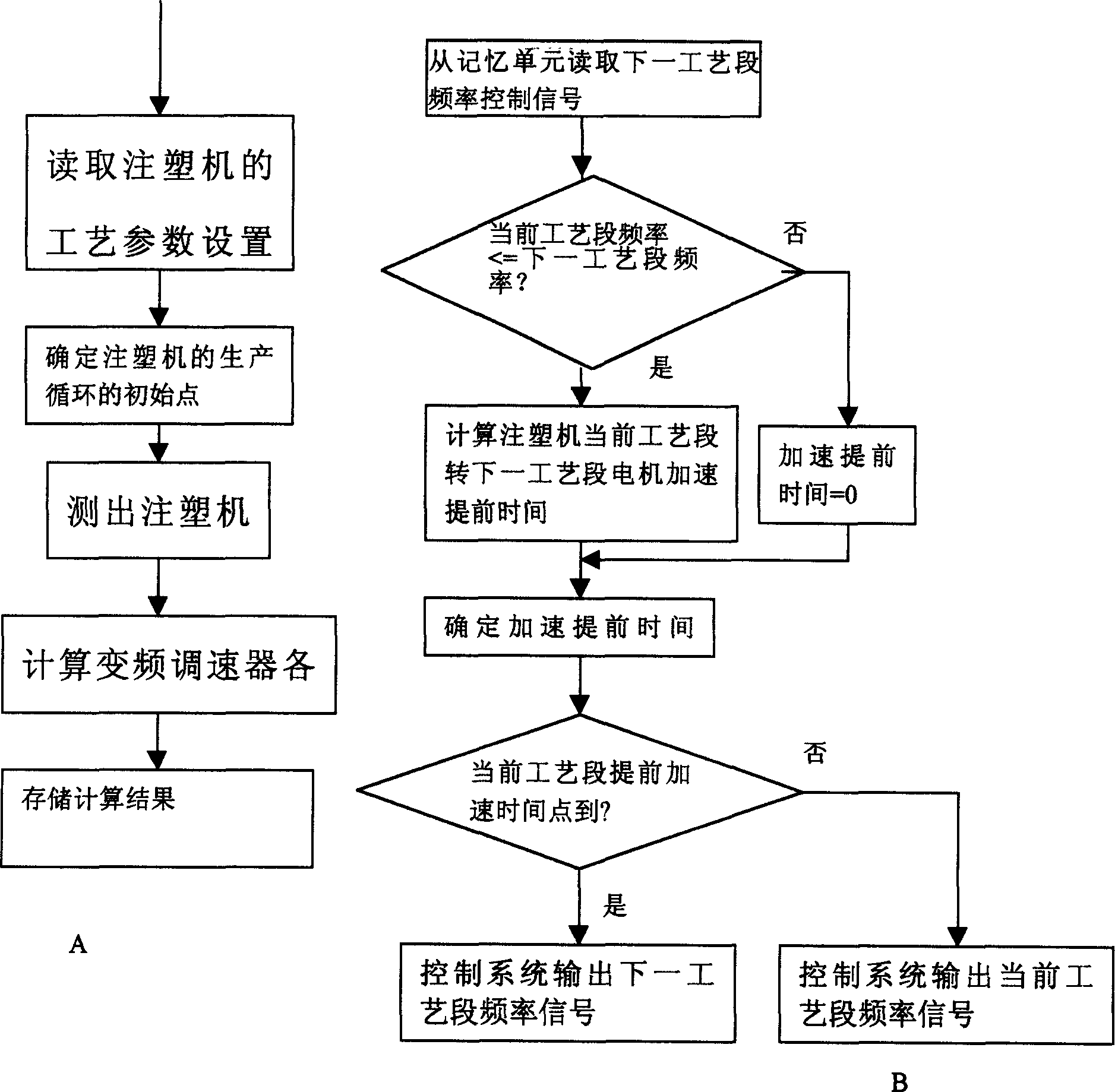

[0032] Fig. 1, Fig. 2 are two kinds of realization forms of the present invention respectively, shown in the figure is a kind of control device based on the energy-saving variable frequency speed regulator to improve the production efficiency of injection molding machine, the control device in the present invention is called signal acquisition here Processing device, the control device is used to receive the process parameters and working status signals of the injection molding machine, calculate the frequency control signal value Fx of the frequency converter in each process section and the acceleration time point Sx of the motor in advance, and output the frequency control signal to the motor connected to the injection molding machine A frequency converter to control the running speed of the motor;

[0033] The control device can be integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com