Photosensitive composition and lithograph plate made of same

A composition and lithographic technology, applied in the field of lithographic printing plates, can solve the problems of reducing the printing endurance, the printing endurance, the adaptability of high-sensitivity development and the difficulty of hydrophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention comprises heat-crosslinking resin, latent protonic acid, infrared absorbing compound and acid proliferating agent, the amount of resin accounts for 30% of the total solids of the composition, and the amount of infrared absorbing compound accounts for the total solids of the composition The amount of potential protonic acid accounts for 60% of the total solids of the composition, and the amount of acid multiplier accounts for 5% of the total solids of the composition.

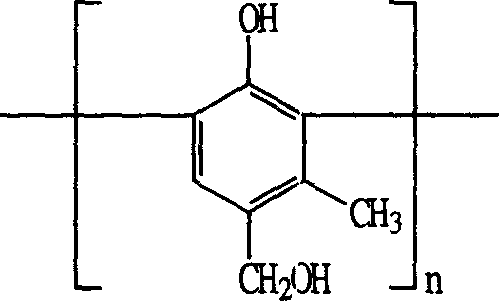

[0030] The heat-crosslinkable resin is a methylolation product of m-cresol resin, which has the following structure:

[0031]

[0032] n is a natural number of 1-12.

[0033] The heat-crosslinkable resin is obtained by using m-cresol or mixed phenol phenolic resin and formaldehyde or paraformaldehyde as raw materials, acetone or ethanol as solvent, and basic compound as catalyst, reacting under reflux and distilling under reduced pressure.

[0034] The basic compound used as catalyst in ...

Embodiment 2

[0042] In the present invention, the heat-crosslinkable resin, potential protonic acid, infrared absorbing compound and acid multiplying agent are included, and the amount of the resin accounts for 60% of the total solids of the composition, and the amount of the infrared absorbing compound accounts for 60% of the total solids of the composition. 10% of the total amount, the amount of potential protonic acid accounts for 30% of the total solids of the composition, and the amount of acid multiplier accounts for 0% of the total solids of the composition.

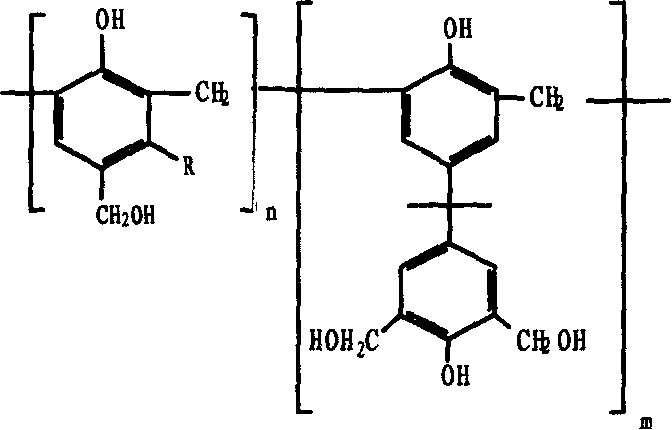

[0043] Described heat-crosslinkable resin is the methylolation product of mixed phenolic resin, and it has following structure:

[0044]

[0045] In the formula, R represents a hydrocarbon group, alkoxyl group, aryl group, halogen atom, etc. of 1-12 carbons, which is a hydrocarbon group or alkoxyl group or an aryl group of 1-6 carbons, and m, n represent a range between 1-12 Natural number.

[0046] The heat-crosslinkable ...

Embodiment 3

[0057] The present invention comprises heat-crosslinking resin, latent protonic acid, infrared absorbing compound and acid proliferating agent, the amount of resin accounts for 35% of the total solids of the composition, and the amount of infrared absorbing compound accounts for the total solids of the composition The amount of potential protonic acid accounted for 45% of the total solids of the composition, and the amount of acid multiplier accounted for 10% of the total solids of the composition.

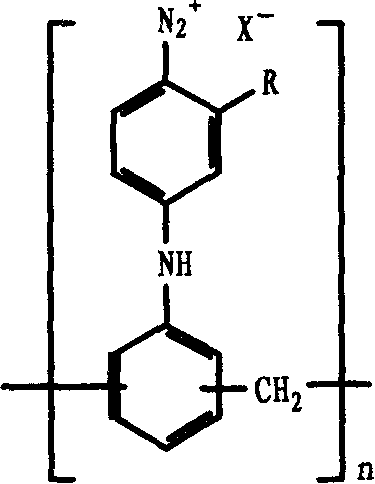

[0058] The photosensitive composition according to claim 1 or 2 in the present invention is characterized in that: the thermally crosslinkable resin is a methylolation product of m-cresol aldehyde resin, which has the following structure:

[0059]

[0060] n is a natural number of 1-12.

[0061] The heat-crosslinkable resin is obtained by using m-cresol or mixed phenol phenolic resin and formaldehyde or paraformaldehyde as raw materials, acetone or ethanol as solvent, and basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com