Hydraulic commutation clutch and multifunctional tractor employing the same

A clutch and hydraulic technology, applied in the field of clutches, can solve problems such as short service life, oil leakage in the system, and many assembly links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

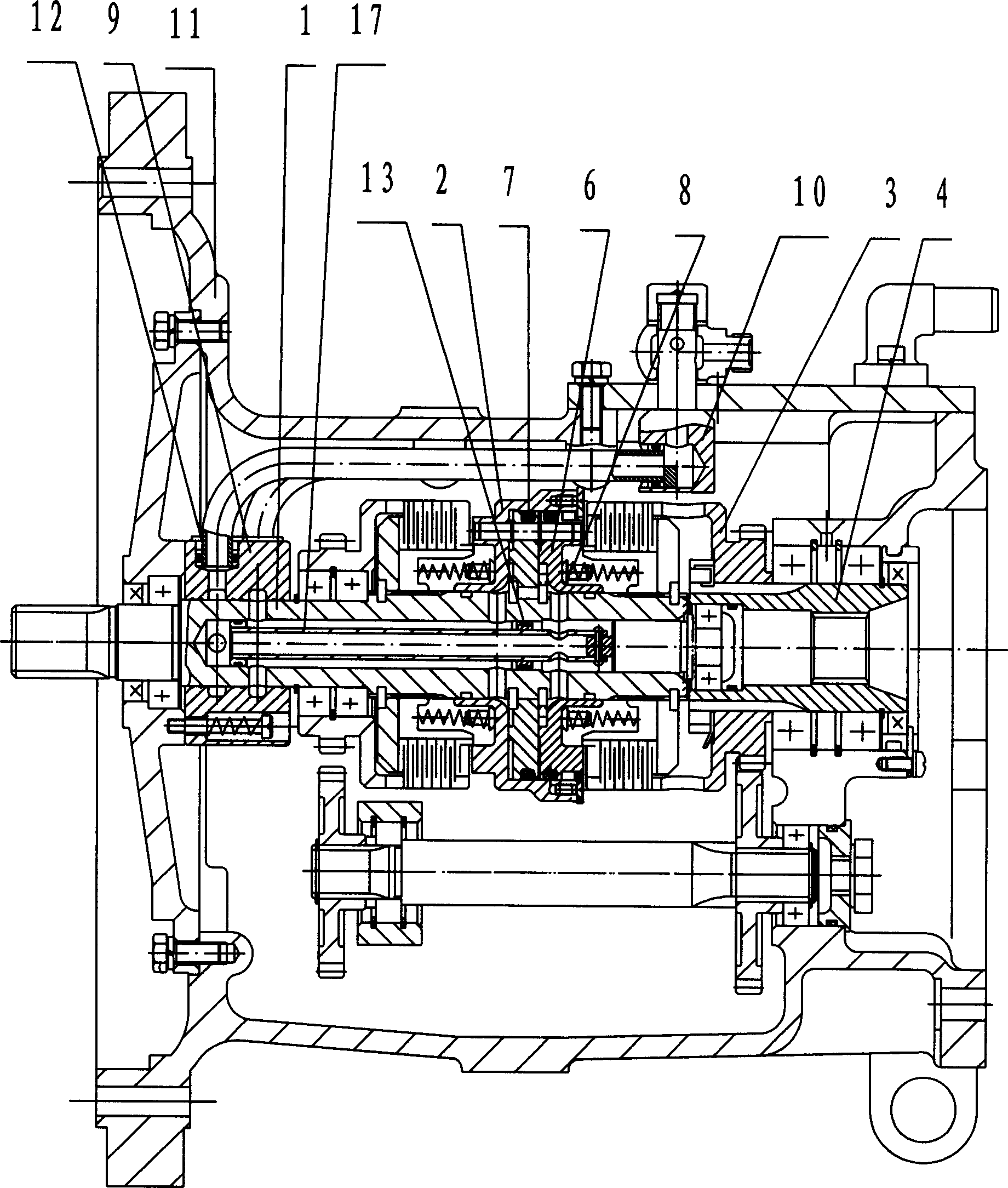

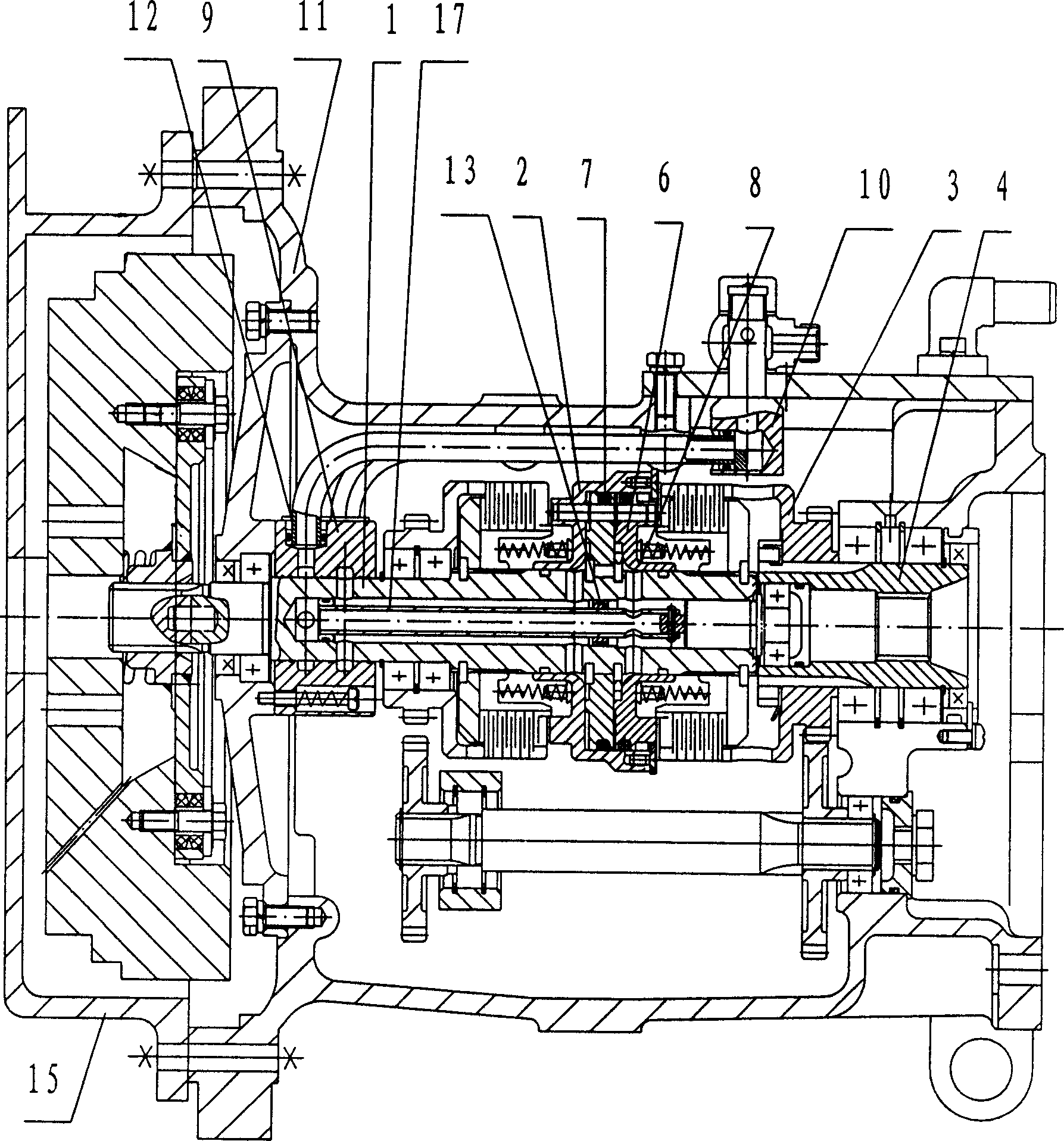

[0039] exist image 3 In the illustrated embodiment, the hydraulic reversing clutch includes a housing 11 and front and rear end covers, the driving shaft 1 and the driven shaft 4 are fitted on the front and rear end covers through the assembly bearing 5, and the front and rear clutches are assembled On the driving shaft 1, the working oil cylinder 2 is fixedly connected with the driving shaft 1, the rear clutch gear 3 is connected with the driven shaft 4, and the distribution sleeve 9 is set outside the driving shaft 1 and fixedly connected to the front end cover with bolts. The casing 11 is provided with two transition joints 10 for connecting with external pipelines, and the two transition joints 10 are respectively connected to one end of the two shifting oil passages 12 arranged in the casing 11, and the shifting oil passages 12 can be existing There is any structure in the clutch, such as two suspended gear oil pipes, but in order to make the structure of the hydraulic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com