In cylinder fuel oil jet type IC engine

A technology of internal injection and internal combustion engine, which is applied to internal combustion piston engine, combustion engine, and the fuel is brought into the engine through high-pressure gas. Good performance, suppression of rarefaction, and improvement of ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

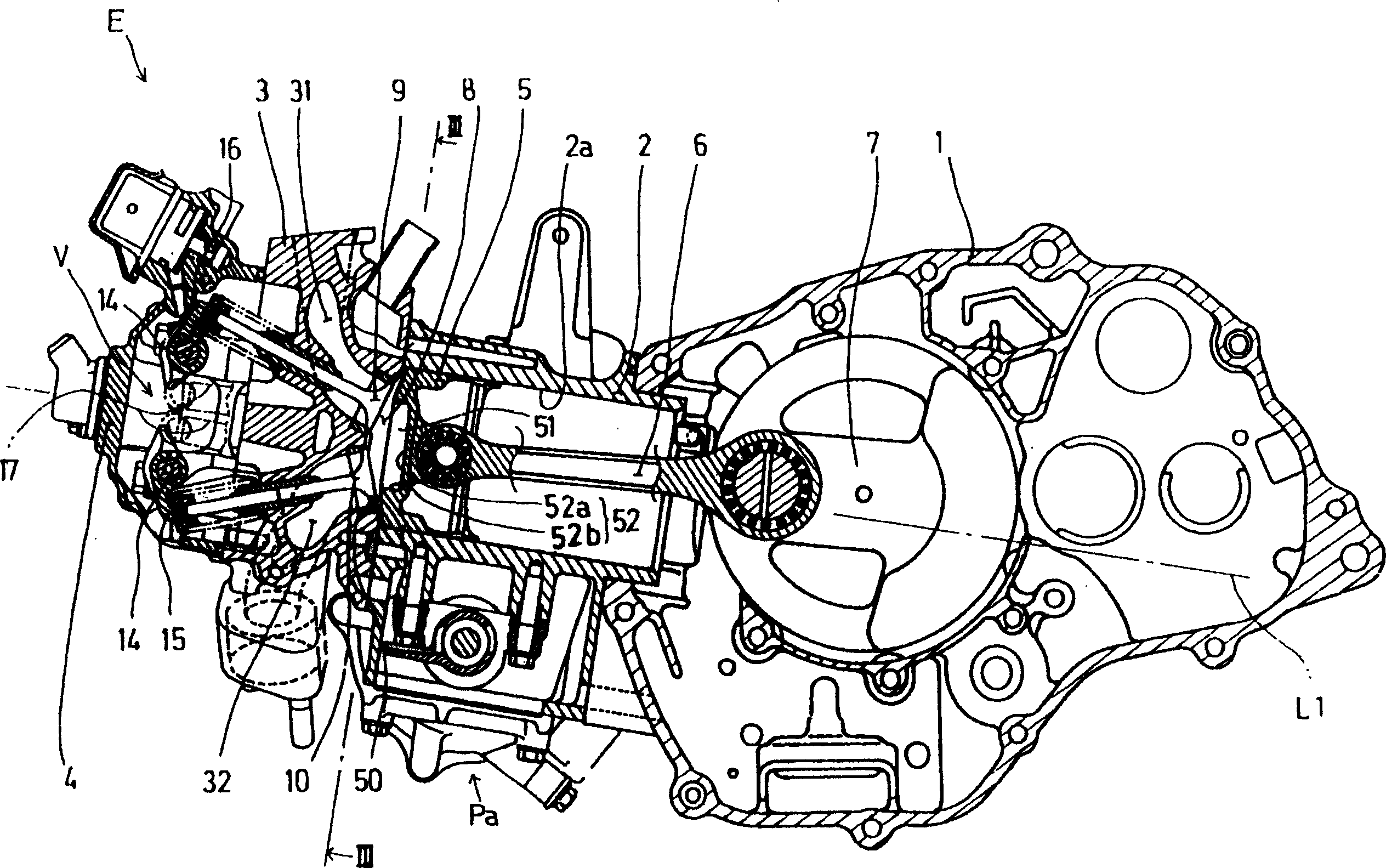

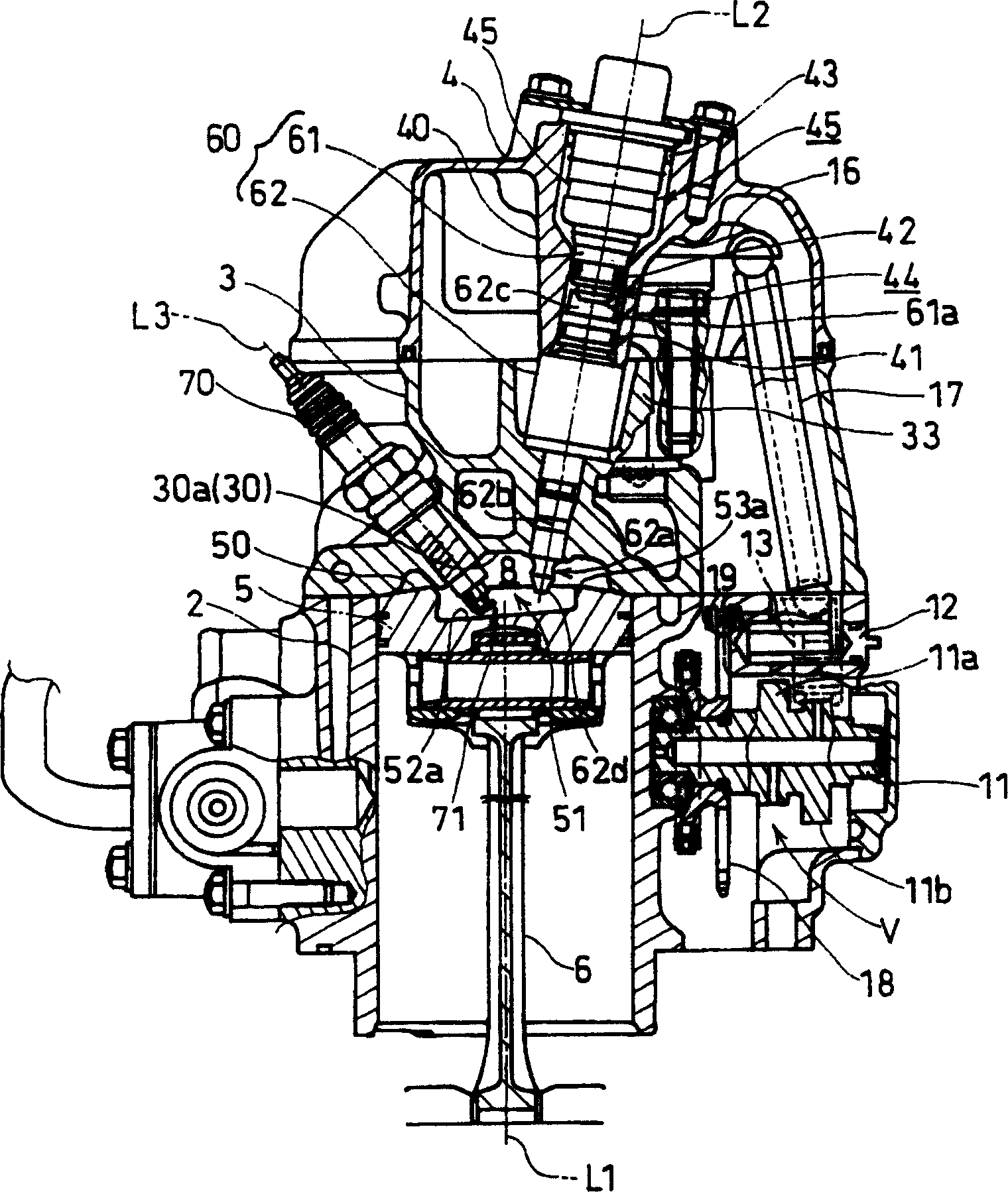

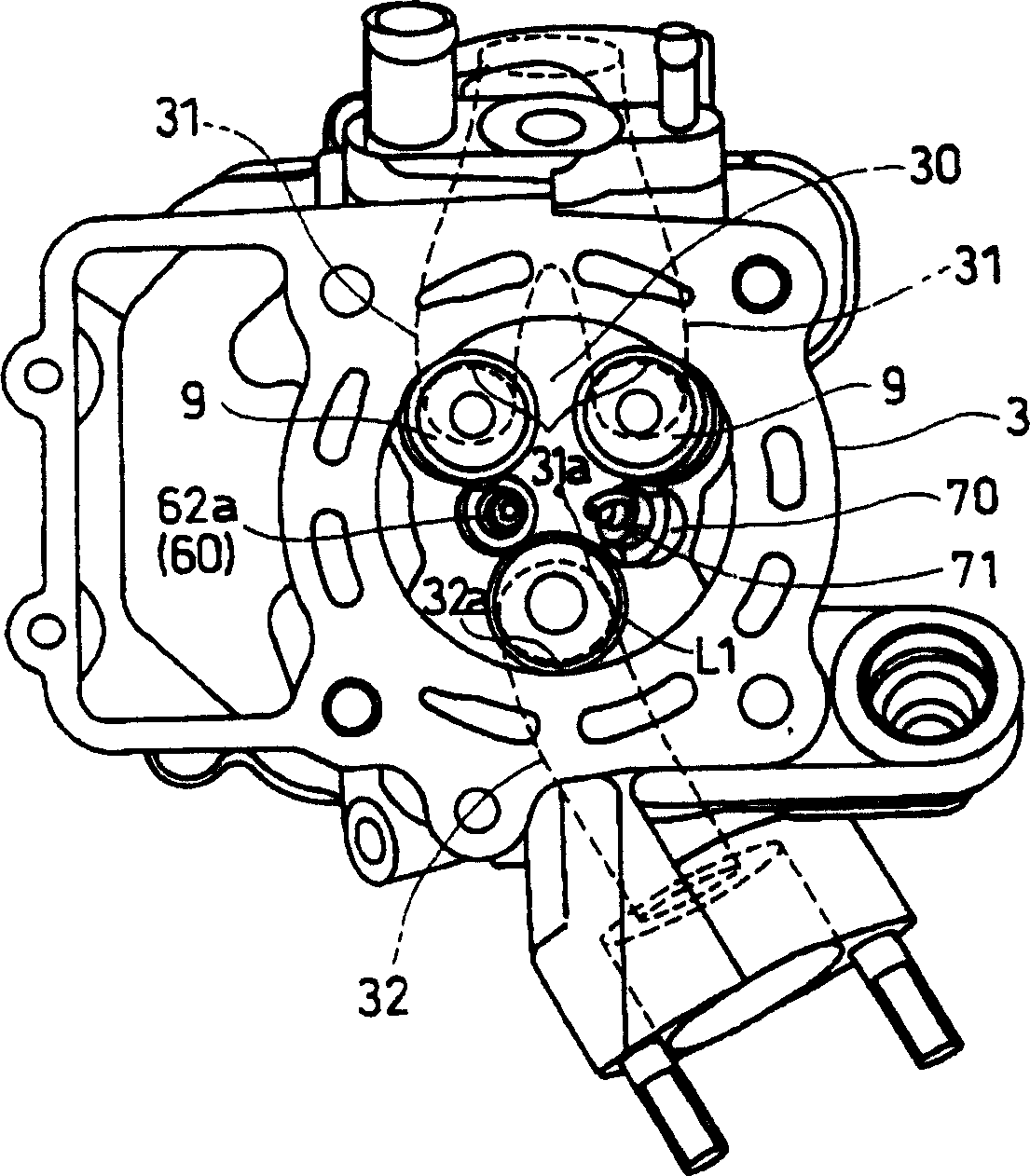

[0028] Hereinafter, an embodiment of the present invention is based on Figure 1 to Figure 5 Be explained.

[0029] refer to figure 1 , figure 2 , the fuel injection type internal combustion engine E applied in the cylinder of the present invention is a spark ignition type 4-stroke single-cylinder internal combustion engine, having a cylinder 2 coupled to a crankcase 1 that rotatably supports a crankshaft 7, and a cylinder 2 coupled to the upper end of the cylinder 2 A cylinder head 3, and a cylinder head cover 4 coupled to the upper end of the cylinder head 3.

[0030] A piston 5 reciprocally fitted in a cylinder bore 2 a of the cylinder 2 rotatably drives a crankshaft 7 via a connecting rod 6 .

[0031] And, the internal combustion engine E such as figure 1 As shown, the cylinder 2 located in front of the vehicle with respect to the crankshaft 7 is mounted on the motorcycle in a state inclined slightly upward of the vehicle.

[0032] Between the cylinder 2 and the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com