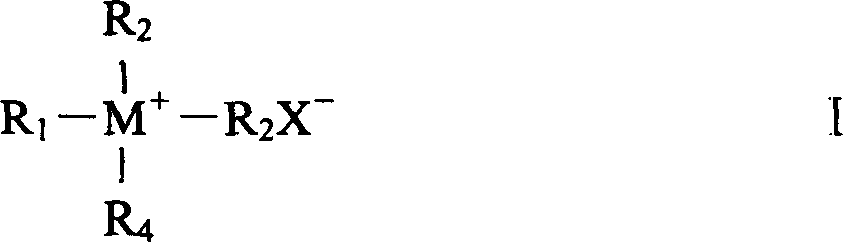

Preparation for water soluble high-molecular weight cationic polymer

A cationic polymer, high molecular weight technology, applied in the field of water-soluble high molecular weight cationic polymer, can solve the problems of low purity, low molecular weight, small intrinsic viscosity, etc., and achieve the effect of simple polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 30g of acrylamide, 0.5g of 2-acryloyloxyethyltrimethylammonium chloride, and 70g of deionized water, add them into a three-neck flask, stir and mix evenly, and prepare a solution with a required monomer concentration of 30wt%; Add 0.004g of disodium diaminetetraacetic acid, 0.005g of sodium formate, 0.0025g of sodium perborate, and 0.002g of ammonium persulfate (APS) into a three-necked flask; place the three-necked flask in a constant temperature water bath at 30°C, and pass through nitrogen to remove oxygen for 15 Minutes later, add 0.004 g of sodium bisulfite, continue to pass nitrogen for 5 minutes, and pass nitrogen protection; after standing for 5 hours, take out the rubber block, granulate, dry, crush, and sieve to obtain 20-100 mesh, Intrinsic viscosity 23.4dl / g white powder cationic polymer product (intrinsic viscosity [η] is measured at 25±0.05°C in 1mol / L NaCl aqueous solution).

Embodiment 2

[0019] Weigh 17.41g of acrylamide and 25.46g of 2-acryloyloxyethyltrimethylammonium chloride, add deionized water to prepare a total liquid volume of 100g, add them into a three-necked flask, stir and mix evenly, and prepare the required monomer concentration of 38wt% solution; EDTA disodium 0.001g, sodium formate 0.003g, sodium perborate 0.003g, potassium persulfate (KPS) 0.0025g, add in the three-necked flask; place the three-necked flask in a constant temperature water bath at 30°C In the process, after passing nitrogen for 15 minutes to remove oxygen, add 0.005 g of sodium methyl sulfoxylate, continue passing nitrogen for 5 minutes, and pass nitrogen bag for protection; after standing for 20 hours, take out the rubber block, granulate and dry , crushing, and sieving to obtain a white powdery cationic polymer product of 20 to 100 meshes and an intrinsic viscosity of 18.2dl / g.

Embodiment 3

[0021] Weigh 75g of 2-acryloyloxyethyltrimethylammonium chloride, 0.7g of acrylamide, and 25g of deionized water, add them into a three-necked flask, stir and mix evenly, and prepare a solution with a required monomer concentration of 60wt%. Add 0.002g of disodium diamine tetraacetate, 0.002g of sodium formate, 0.0015g of sodium perborate, and 0.0015g of ammonium persulfate (APS) into a three-necked flask; place the three-necked flask in a constant temperature water bath at 30°C, and pass through nitrogen to remove oxygen for 15 Minutes later, add 0.003 g of sodium thiosulfate, continue to pass nitrogen for 5 minutes, and pass nitrogen protection; after standing for 24 hours, take out the rubber block, granulate, dry, crush, and sieve to obtain 20-100 mesh, Intrinsic viscosity 15.2dl / g white powder cationic polymer product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com