Multi-arm star-type thermoplastic elastomer synthesizing method

A technology of thermoplastic elastomer and synthesis method, which is applied in the field of synthesis of known polymer compounds, can solve the problems of wide molecular weight distribution of block polymers, few properties of thermoplastic elastomers, poor physical properties, etc., and achieve low homopolymer content , high molecular weight and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

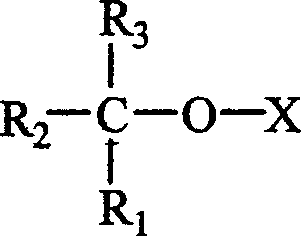

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Linear polyisobutylene-polystyrene block thermoplastic elastomer

[0039] At normal pressure, reaction temperature -75--80°C, under the protection of dry nitrogen, add 1L mixed solvent, 1×10 -3 mol / L Benzoyl Chloride, 0.04mol / L TiCl 4 , 1.2×10 -3 mol / L hexahydropyridine was aged for 15 minutes, and wasobutene was added to keep the concentration at 2.8mol / L. After reacting for 1 hour, the end-capping agent 1,1-diphenylethylene was added, and the concentration was 6×10 -3 mol / L, age for 15 minutes, add plastic hard segment monomer or its concentration is 0.6mol / L, continue to react for 1 hour, add methanol dissolved in 5% HCl to the system to terminate, pour the solution after termination The product precipitated out in ethanol solution, was filtered and dried.

[0040] The block thermoplastic elastomer product has a number average molecular weight of 25,000, a molecular weight distribution of 1.19, a glass transition temperature of 197°C, a tensile strength o...

Embodiment 2

[0041] Embodiment 2: multi-arm star polyisobutylene-polystyrene block thermoplastic elastomer

[0042] At normal pressure, reaction temperature -75--80°C, under the protection of dry nitrogen, add 1L mixed solvent, 1×10 -3 mol / L pyromellitic acid chloride, TiCl 4 The concentration of 0.16mol / L, the concentration of hexahydropyridine is 1.2×10 -3 mol / L, the concentration of isobutylene is 11.2mol / L, the concentration of end-capping agent 1,1-diphenylethylene is 0.024mol / L, and the concentration of plastic hard segment monomer styrene is 2.4mol / L.

[0043] The block thermal elastomer product has a number average molecular weight of 220,000, a molecular weight distribution of 1.26, a tensile strength of 26 MPa, and an elongation of 750%.

[0044] While applying for a patent for the synthesis method of the present invention, a patent for the initiation system was also applied for.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com