Axial flux motor driven anode target for x-ray tube

An X-ray tube and axial flux technology, applied in the field of X-ray tubes, can solve problems such as excessive static load and dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

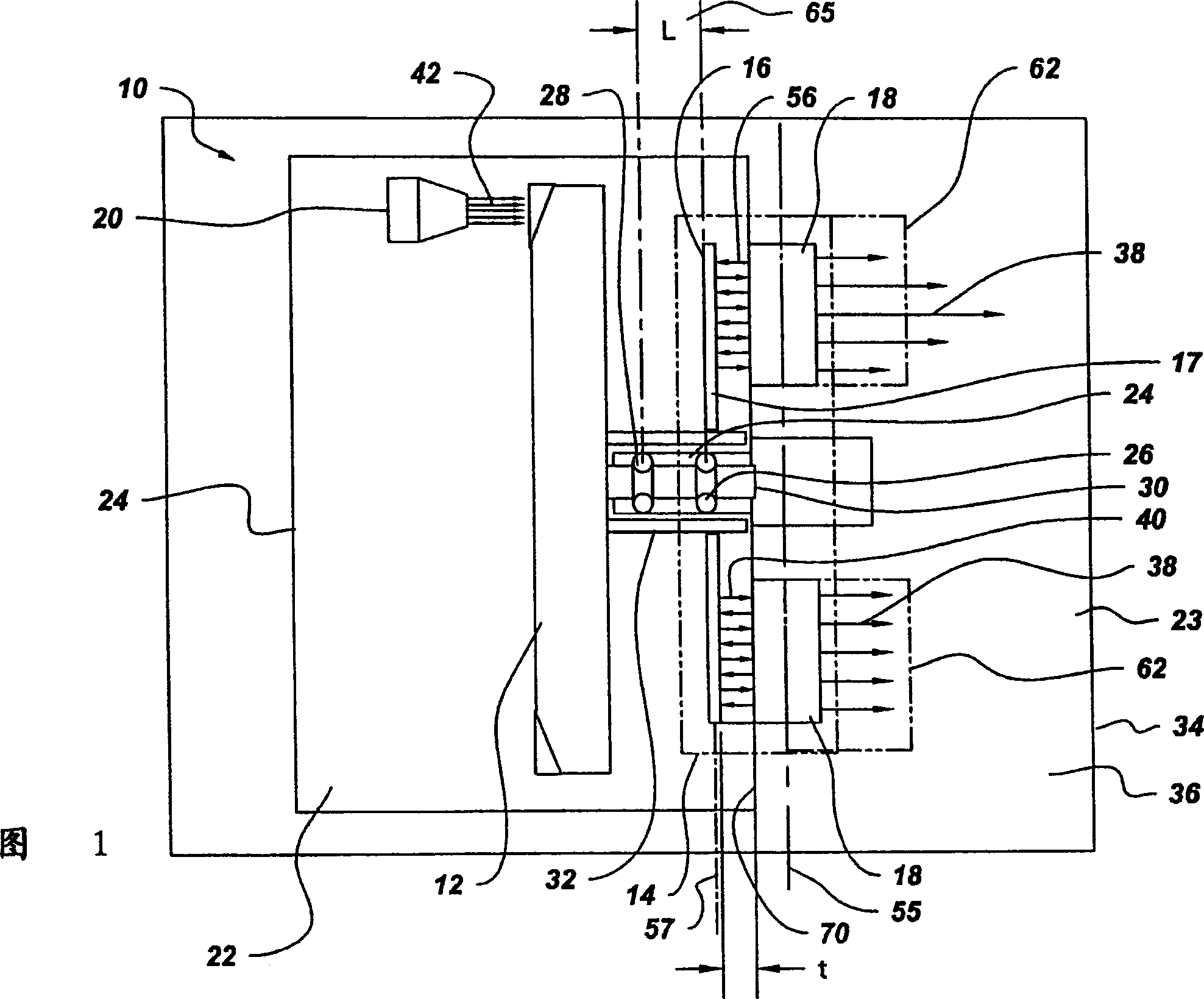

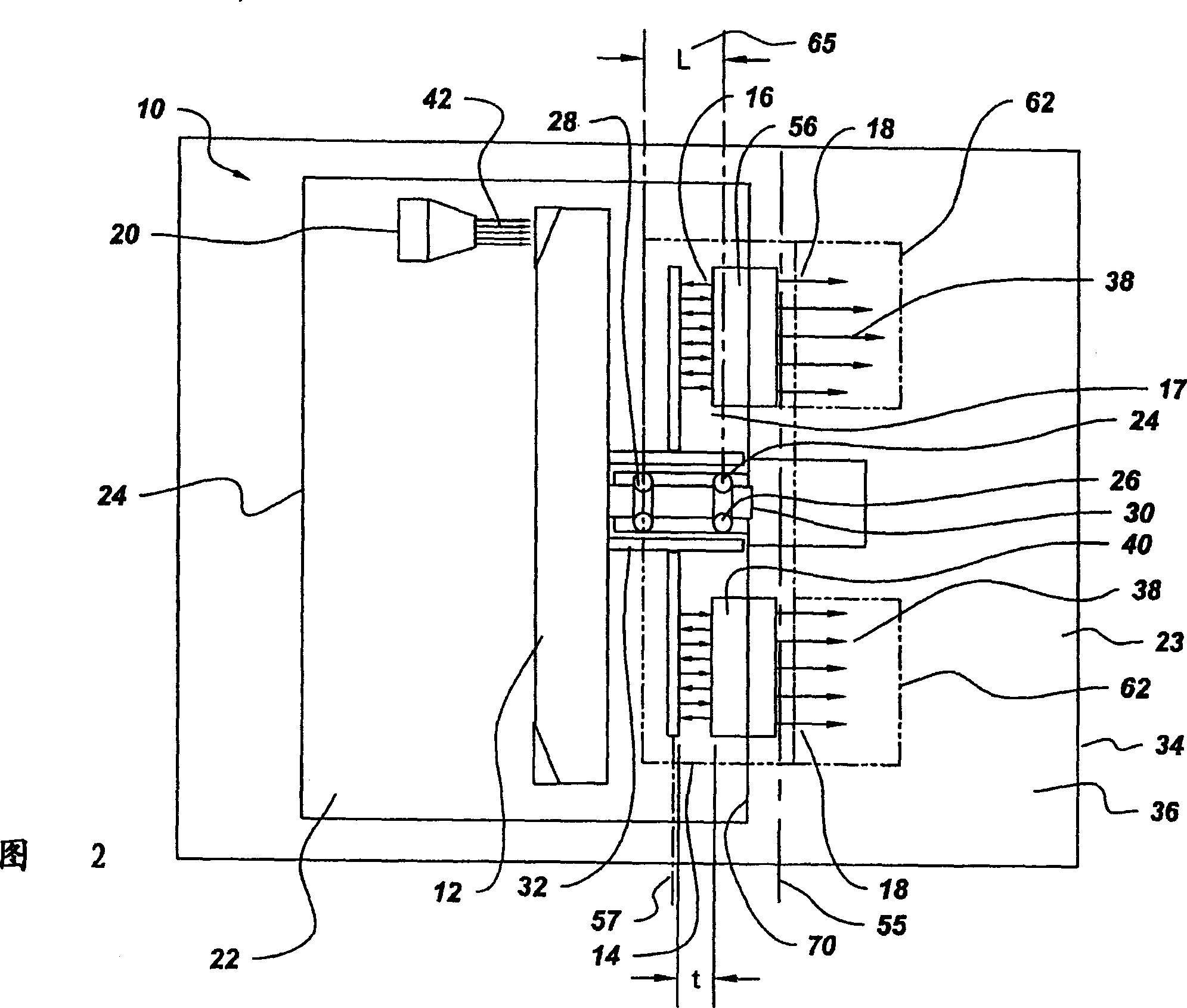

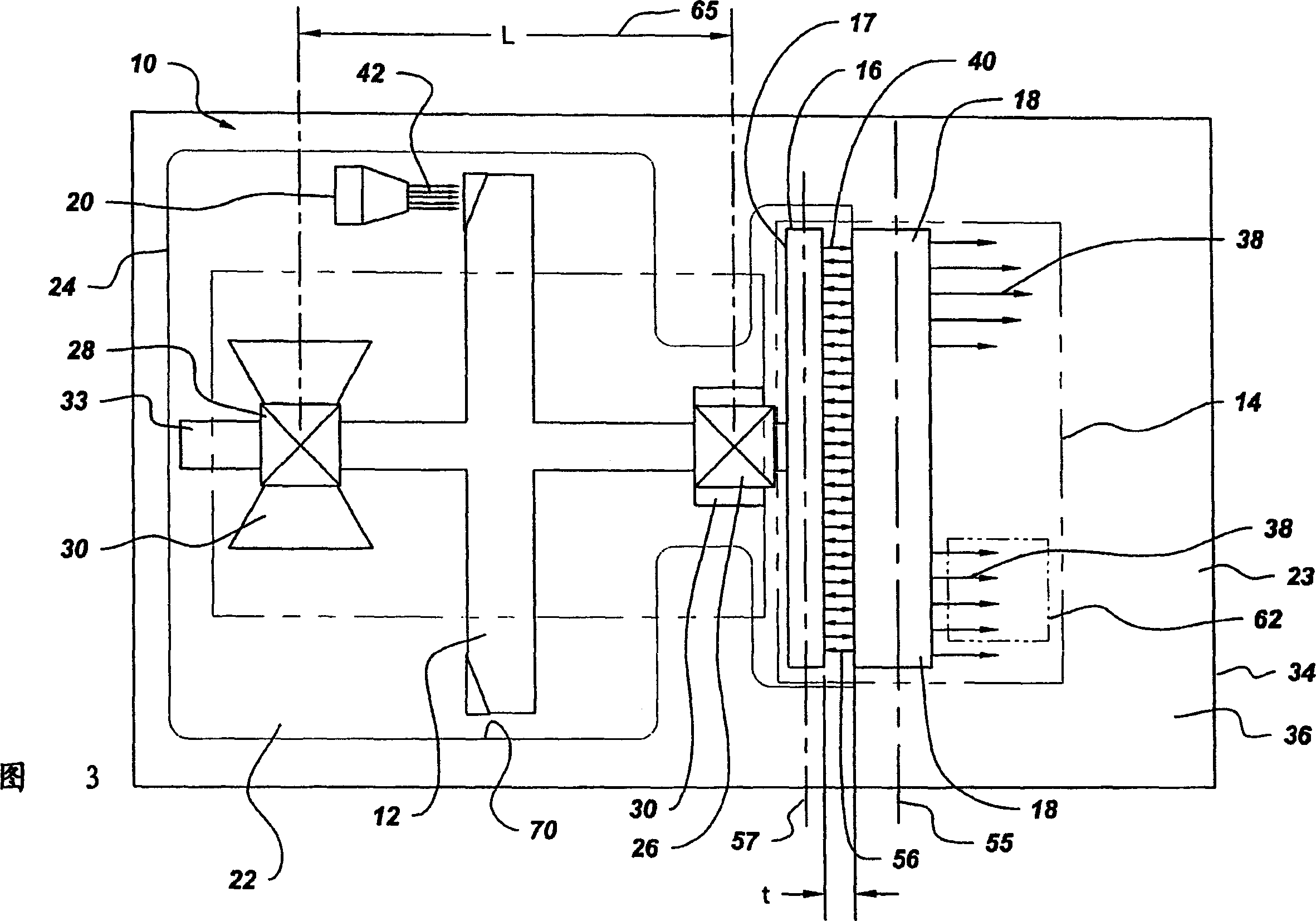

[0026] An X-ray generator, also called an X-ray tube 10 , is shown in FIGS. 1 to 6 . X-ray tube 10 includes an anode target assembly 12 . Anode target assembly 12 is typically fabricated from a relatively high atomic number metal such as tungsten or a tungsten alloy, molybdenum or rhenium, for example. A cathode filament (not shown) disposed within cathode assembly 20 is heated, thereby emitting an electron beam 42 . A potential difference, typically on the order of about 60 kilovolts to 140 kilovolts, is applied between cathode assembly 20 and anode target assembly 12 to accelerate electron beam 42 generated by cathode assembly 20 . Once accelerated, electron beam 42 impinges on anode target assembly 12 to generate electromagnetic radiation. This electromagnetic radiation is typically X-ray radiation.

[0027] A portion, typically about 1%, of the kinetic energy of the electron beam 42 is converted into x-ray radiation, while the remainder is converted into thermal energy....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com