High repetition frequency high precision rotating disk type mechanical shutter device

A high repetition frequency, mechanical shutter technology, applied in the direction of using optical devices to transmit sensing components, can solve the problems of the complex structure of the mechanical shutter device, the inability to achieve the repetition frequency and time setting accuracy of thousands of hertz at the same time, and reduce the transition. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

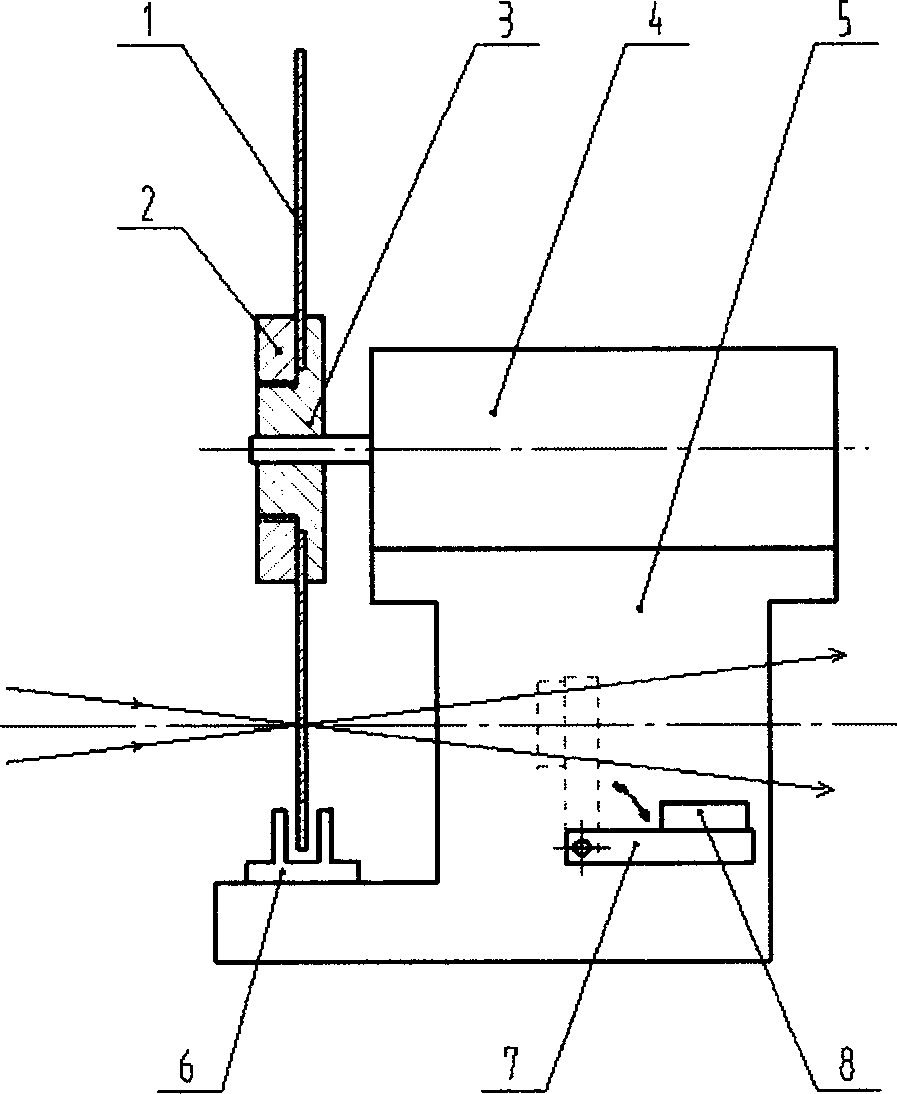

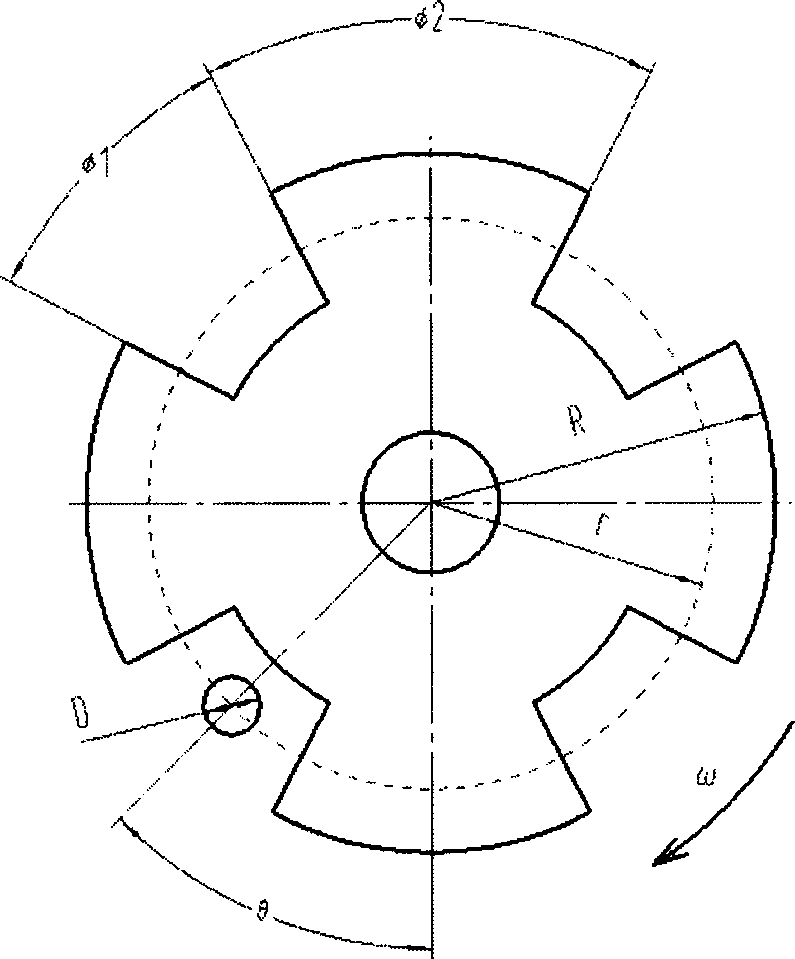

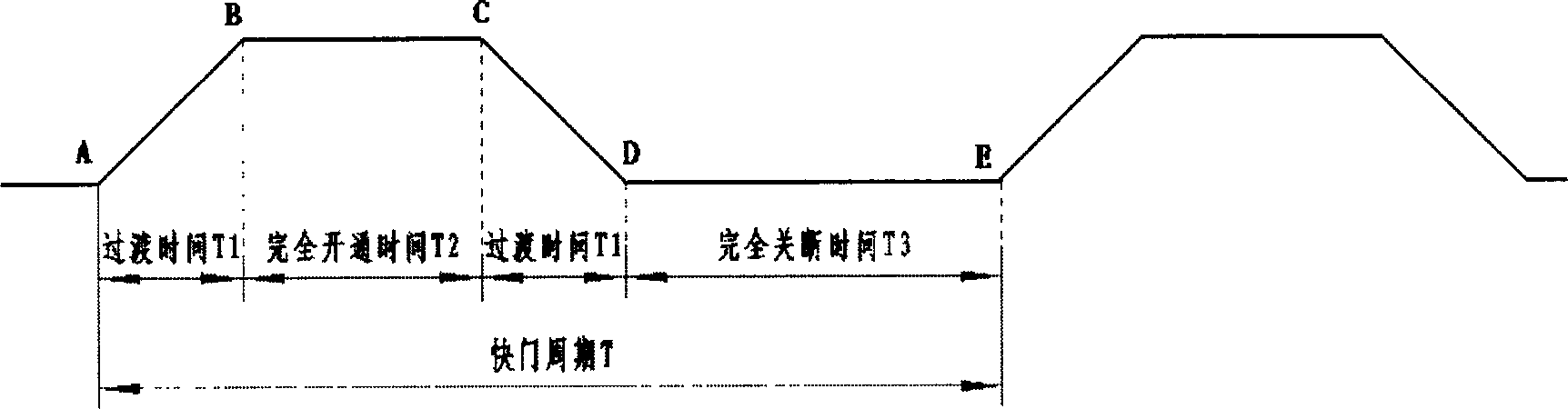

[0013] Such as figure 1 As shown, an opaque thin disc 1 with several axisymmetric openings is directly fixed on the shaft head of the high-speed motor 4 through the reverse threaded set nut 2 and the bushing 3, and the high-speed motor 4 and the photoelectric switch 6 are fixed On the base 5, a high-response speed photodiode 8 is installed at the rear position where the signal beam passes through the turntable 1, and the photodiode 8 is installed on a cantilever 7 that can be freely put into the optical path or taken away. The opening on the turntable 1 is not only the light-through hole for the incident signal, but also the positioning hole for the photoelectric switch 6. When the non-transparent part of the turntable 1 passes through the photoelectric switch, the photoelectric switch 6 gives a low-level signal; The opening passes through the photoelectric switch 6, and the photoelectric switch 6 gives a high-level signal. When the turntable 1 rotates continuously, the photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com