Novel configuration phenyl methyl silicon oil

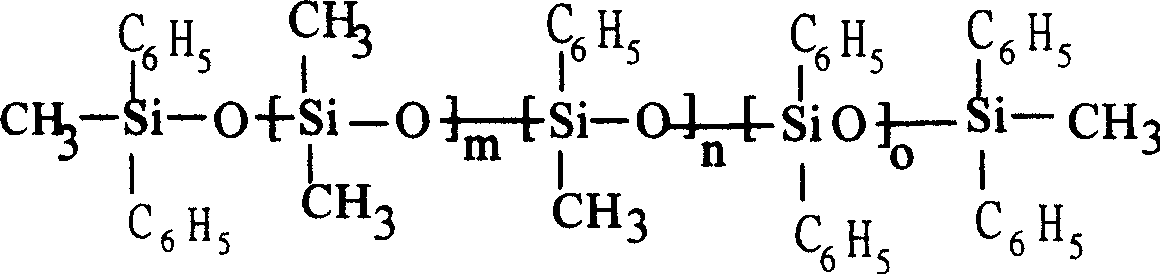

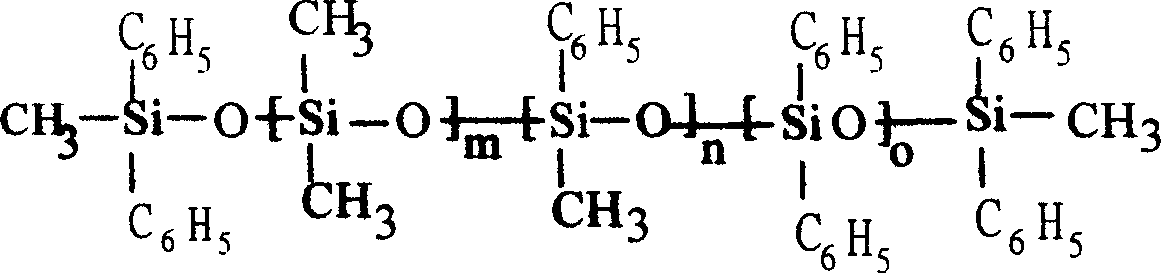

A technology of phenylmethyl silicone oil and a new structure, which is applied in medical science, prosthesis and other directions, can solve the problems of inability to meet the viscosity requirements, the negative charge and high temperature resistance performance are not ideal, and achieve the effect of low cost and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

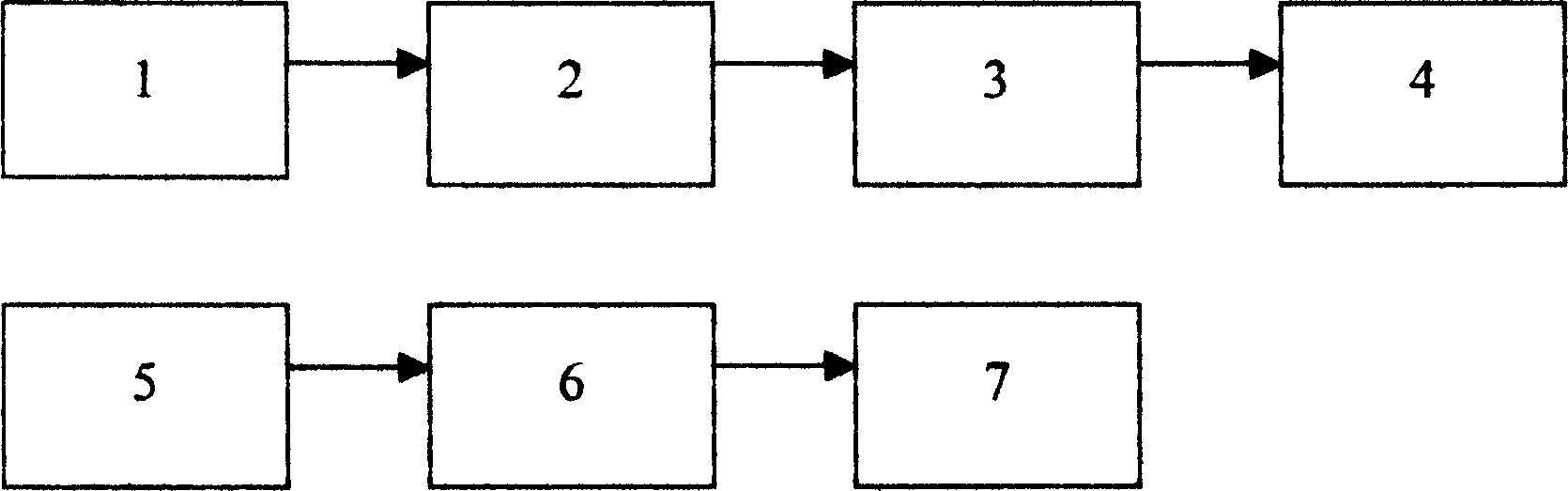

Method used

Image

Examples

Embodiment 1

[0027] Weigh respectively 192g (32%) of low degree of polymerization siloxane (component I) with phenylmethyl as end-capping agent, 81.6g (13.6%) of methylcyclosiloxane (component II), and hydroxy 326.4 g (54.4%) of end-capped low-polymerization dimethyldiphenylsiloxane, and 0.97 g of tetramethylammonium hydroxide aqueous solution (0.1% of the weight sum of the above three components). Add the raw materials of the four components into the reaction bottle, start stirring, turn on the vacuum pump, adjust the vacuum pump to maintain the residual pressure at (40-10)mmHg and start to heat up, when the temperature rises to 40°C, dehydrate at 45°C / 20mmHg After 20 minutes, reduce the vacuum to the residual pressure. At about 200mmHg, start to heat up. When the temperature reaches 85°C, continue dehydration at 85°C / 200mmHg and start the alkali-catalyzed rearrangement reaction. After 0.5 hours, heat up to 115°C , maintain at 115°C / 250mmHg for 2.0 hours, then remove the vacuum, start to ...

Embodiment 2

[0030] Weigh respectively 105g (35%) of low-polymerization siloxane (component I) with diphenylmethylsiloxane as an end-capping agent, 17.7g (5.9%) of methylcyclosiloxane (component II) ), 177.3g (59.1%) of dimethyldiphenylsiloxane (component III) with a low degree of polymerization terminated by hydroxyl groups, 0.67g (0.08% of the weight sum of the above three components) of tetramethylammonium hydroxide solution ) and other four-component raw materials were added, and the synthetic operation was carried out under the same process conditions as in Example 1 to obtain a viscosity (25°C): 720 / mm 2 the s -1 , Refractive index (20°C): 1.5185, flash point (°C): ≥350°C, 229g of phenylmethyl silicone oil, which is a light yellow transparent liquid, removes 37g of low boiling point, and the yield is about 77%.

Embodiment 3

[0032] Take by weighing respectively the low degree of polymerization siloxane (component I) 180g (29.3%) with diphenylmethylsiloxane as end-capping agent, methylcyclosiloxane (component II) 15g (2.4%), 420g (68.3%) of low polymerization degree dimethyl diphenylsiloxane (component II) terminated with hydroxyl groups, 0.97g (0.06% of the weight sum of the above three components) of tetramethylammonium hydroxide aqueous solution, etc. The raw materials of the first component are added, and the synthesis operation is carried out under the same process conditions as in Example 1 to obtain a viscosity (25°C): 1300 / mm 2 the s -1, Refractive index (20°C): 1.5270, flash point (°C): ≥360°C, freezing point <-40°C, 460g of phenylmethyl silicone oil, which is a light yellow transparent liquid, removes 84g of low boiling point, and the yield is about 77 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com