Vehicle-carrying automatically passing neutral section system of electric locomotive

A technology for automatic phase separation and electric locomotives, applied in electric vehicles, electric vehicle charging technology, collectors, etc., can solve problems such as current impact, train impulse, locomotive speed loss, etc., and achieve high reliability, equipment reduction, and automation performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

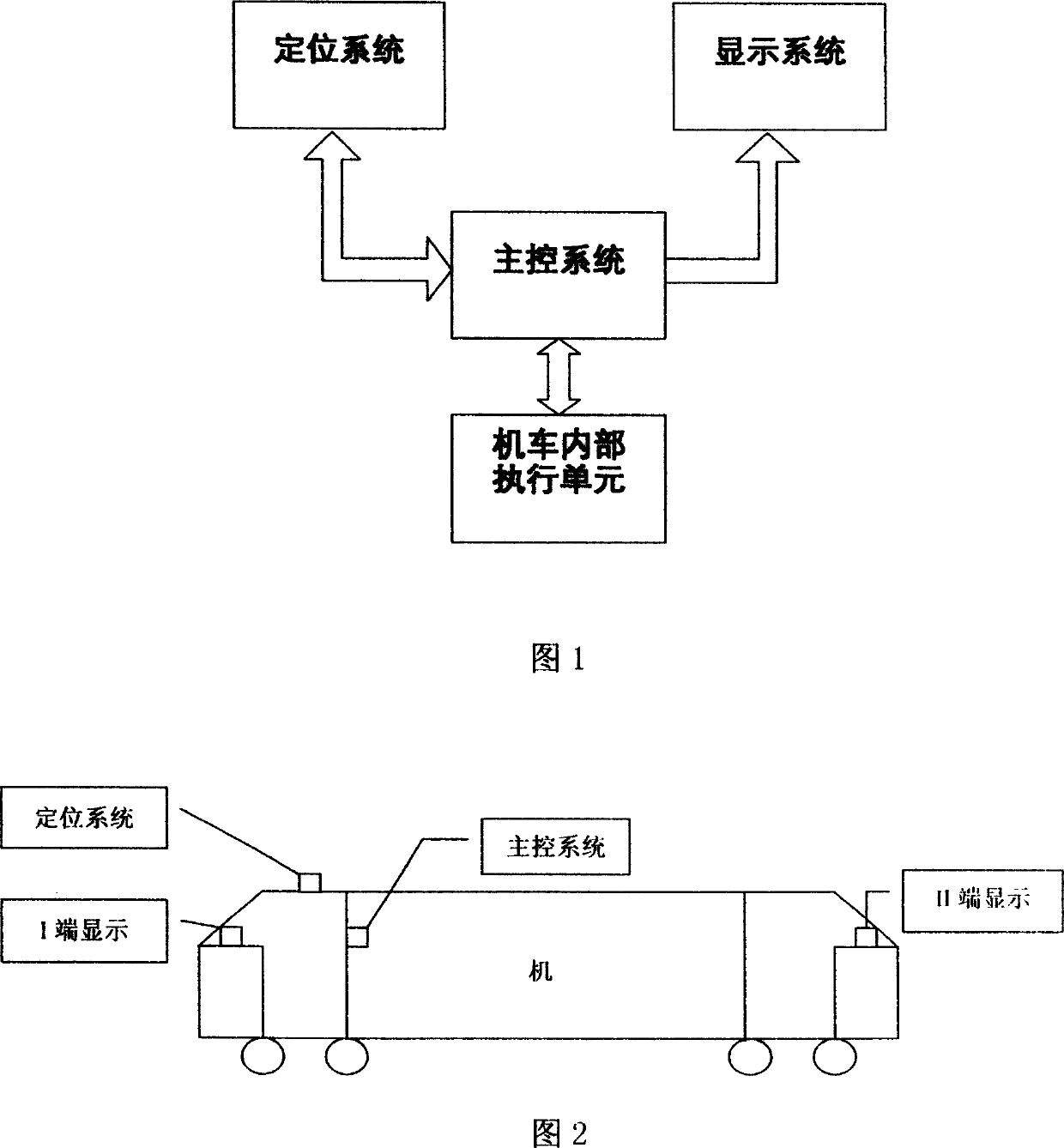

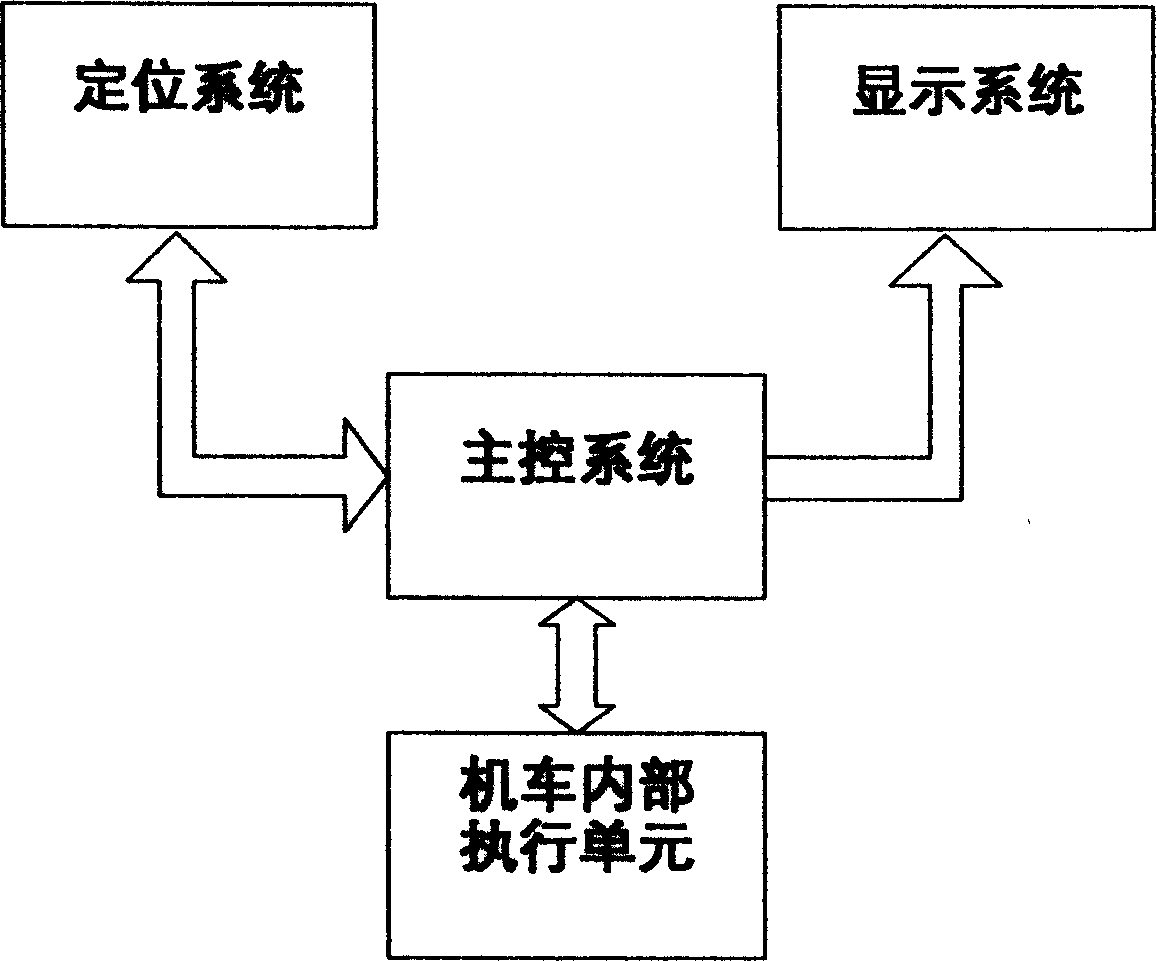

[0035] The vehicle-mounted automatic phase separation system structure of the present invention is shown in Figure 1. The present invention includes a positioning system, a main control system, a display system, and also includes a main control program and a positioning system program. The positioning system and the display system are respectively connected to the main control system through cables, and the positioning system is composed of a radio frequency identification system (RFID) and a GPS satellite positioning system. Positioning system programs include radio frequency identification system (RFID) programs and GPS satellite positioning system programs.

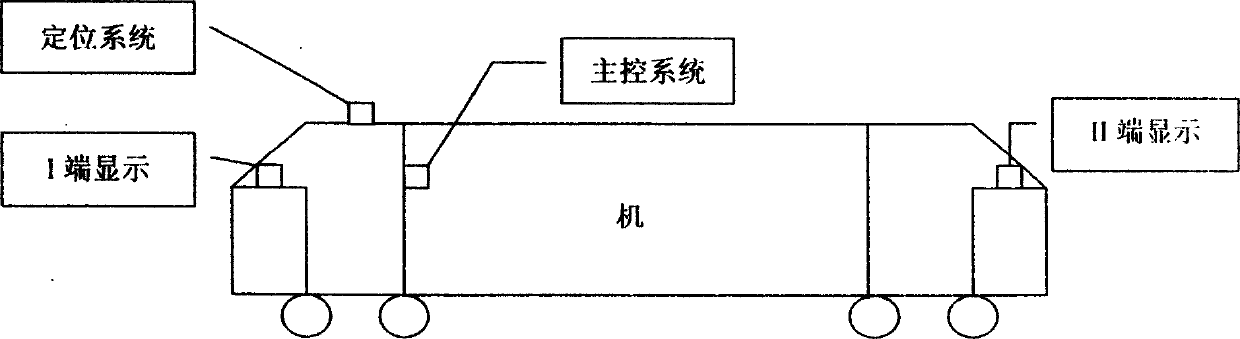

[0036] In Fig. 1 and Fig. 4, the positioning system includes a radio frequency identification system (RFID), which is composed of an identifier and a radio frequency card. The identifier is connected to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com