Method for manufacturing fabric with moisture absorption and sweat discharge performance

A moisture-absorbing and perspiration-absorbing fabric technology, which is applied in textiles, papermaking, and fiber processing, can solve the problems of fabrics not being resistant to washing, high production costs, and slow production speed, and achieve good washing resistance, low cost, and fast production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

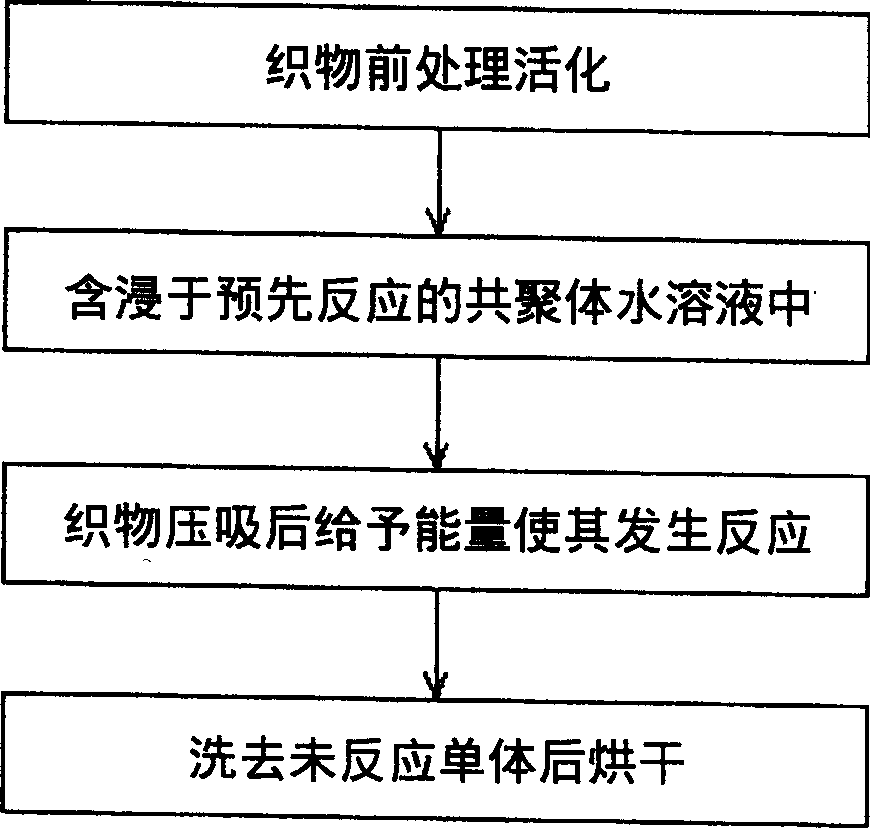

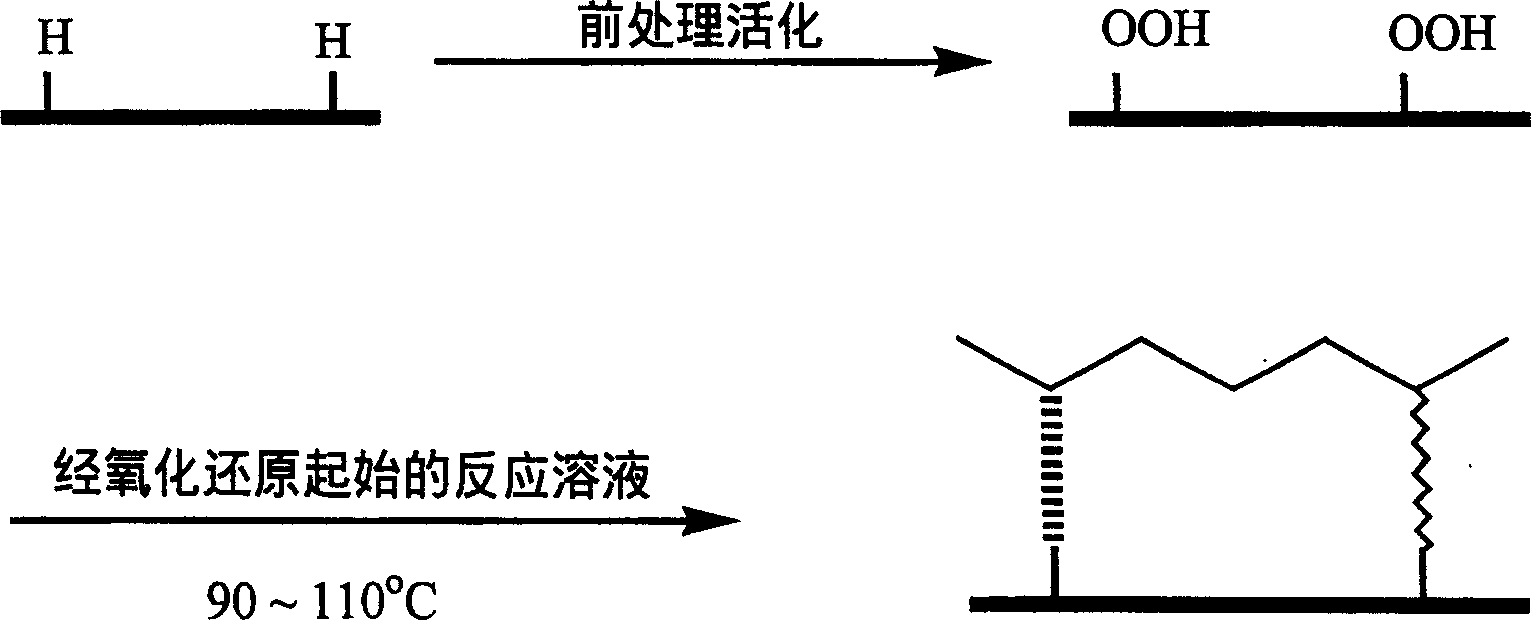

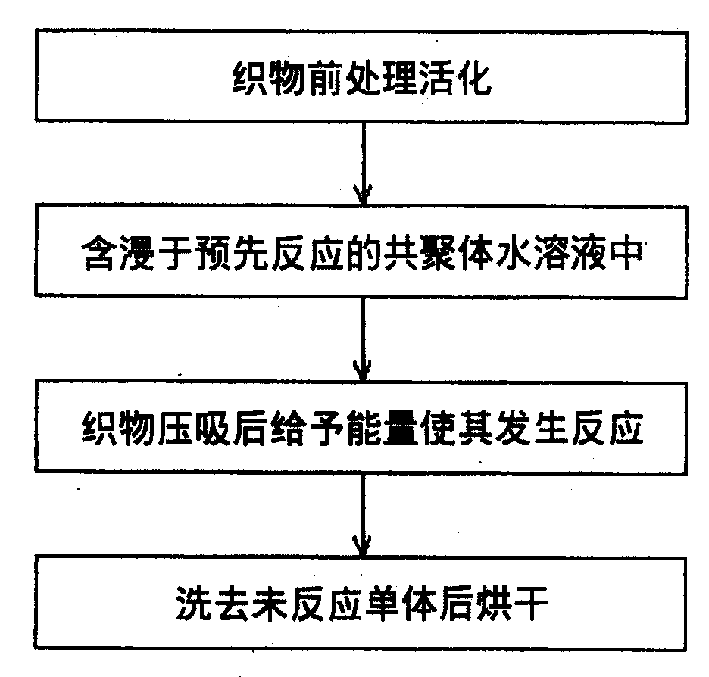

Method used

Image

Examples

Embodiment 1

[0044] A 100% polypropylene knitted fabric with a density of 160 grams per square meter is passed through a corona discharge machine with a total power of 8000 watts at a speed of 0.5 meters per minute to activate the fiber surface. The activated knitted fabric undergoes surface modification for moisture absorption and perspiration by immersion-pressure absorption-baking. The composition of the pressure-absorbent aqueous solution used is: chitosan (molecular weight 340,000g / mol) 1.25%, acrylic acid 5%, polyvinyl alcohol (molecular weight 22,000g / mol) 8.5%, all based on the weight of the overall solution 100% counted. After the chitosan and polyvinyl alcohol in the composition of the pressure-absorbing liquid are completely dissolved, the pressure-absorbing liquid is heated to 50°C, and 0.3% cerium ammonium nitrate (based on the weight of the whole solution as 100%) is added, and the above is soaked The surface of the activated fiber fabric has a baking temperature of 95°C and a re...

Embodiment 2

[0046] The cloth type and pretreatment conditions are the same as in Example 1. The surface modification is carried out by immersion-pressure suction-baking. The composition of the pressure-absorbing water solution is: chitosan (molecular weight 340,000g / mol) 1.25%, acrylic acid 5%, polyvinyl alcohol (molecular weight 22,000g / mol) 8.5%, all based on 100% of the total solution weight. After the chitosan and polyvinyl alcohol in the composition of the pressure-absorbing liquid are completely dissolved, the pressure-absorbing liquid is heated to 50°C, and 0.5% of cerium ammonium nitrate (based on the total weight of the solution as 100%) is added, and the above is soaked The surface of the activated fiber fabric has a baking temperature of 95°C and a reaction time of 120 seconds. The obtained product is the moisture-absorbing and sweat-wicking fabric of the present invention, and the water evaporation rate is shown in Table 1.

Embodiment 3

[0048] The cloth type and pretreatment conditions are the same as in Example 1. The surface modification is carried out by immersion-pressure suction-baking. The composition of the pressure-absorbing water solution is: chitosan (molecular weight 340,000g / mol) 1.25%, acrylic acid 5%, polyvinyl alcohol (molecular weight 22,000g / mol) 8.5%, all based on 100% of the total solution weight. After the chitosan and polyvinyl alcohol in the composition of the pressure-absorbing liquid are completely dissolved, the pressure-absorbing liquid is heated to 50°C, and 0.5% of cerium ammonium nitrate (based on the total weight of the solution as 100%) is added, and the above is soaked Surface activated fiber fabric. The baking temperature is 95°C, and the reaction time is 120 seconds. The obtained product is the moisture-absorbing and sweat-wicking fabric of the present invention, and the water evaporation rate is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com