Safety hot air transferring system for prodn line

An assembly line and safety technology, applied in the field of assembly line safety hot air heating system, can solve the problems of product pollution, affecting product quality, easily damaged heating objects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

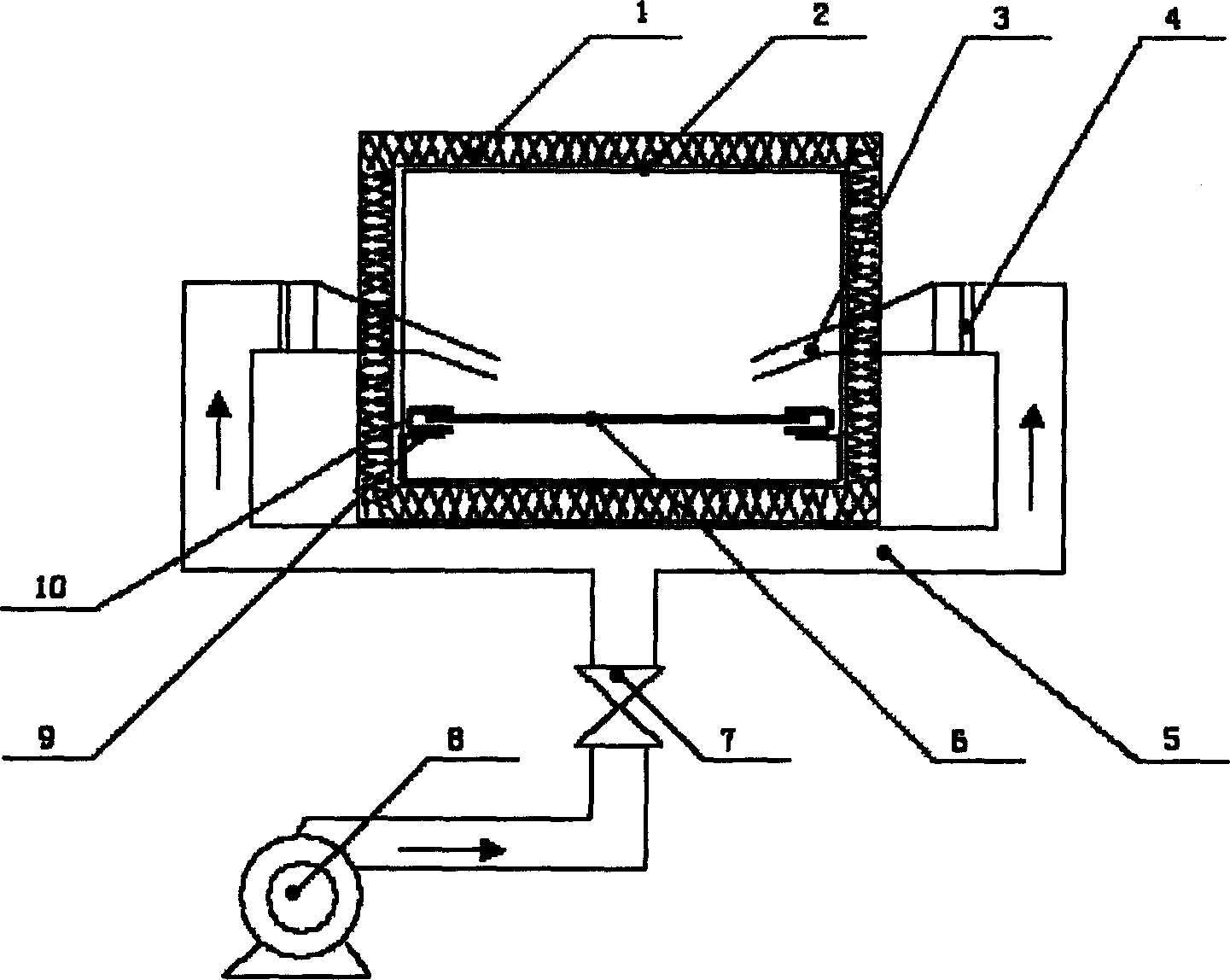

[0008] The assembly line safe hot air heating system has a heating furnace 2, an insulation layer 1 is provided outside the heating furnace, and a guide rail 10 is arranged inside the heating furnace. The guide rail is installed on the support seat 9, and the pipeline chain plate 6 runs on the guide rail 10. A temperature transmitter 11 is installed on the wall, two air supply nozzles 3 are installed on the two side walls of the heating furnace and above the chain plate of the assembly line, and PTC heaters 4 are respectively installed at the rear of the two air supply nozzles, and are respectively connected to the air supply pipes 5 , The air supply pipe 5 is connected with the regulating valve 7 and the blower fan 8 in turn.

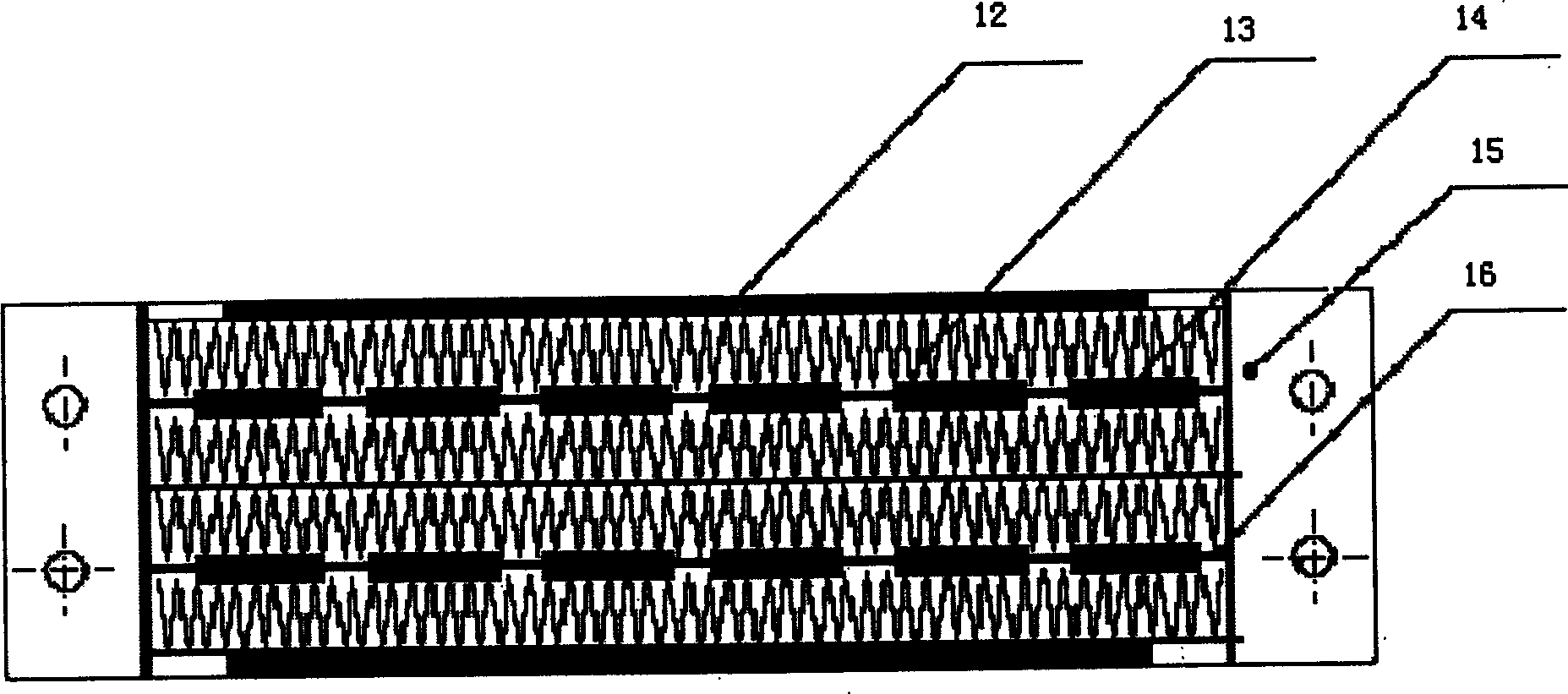

[0009] The PTC heater 4 has a heater bracket 12, the two sides of the heater bracket are provided with PPS engineering plastic mounting brackets 15, and the heater bracket is provided with a PTC ceramic heating element 14, and the two sides of the PTC c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com