Sewerage treatment method by using precoated dynamic membrane to filter mixed liquor of activated sludge

A sewage treatment method and activated sludge technology, which is applied in the field of environmental engineering, can solve the problems of difficult membrane fouling and high cost of membrane modules, and achieve the effects of low cost, low compressibility, and improved filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

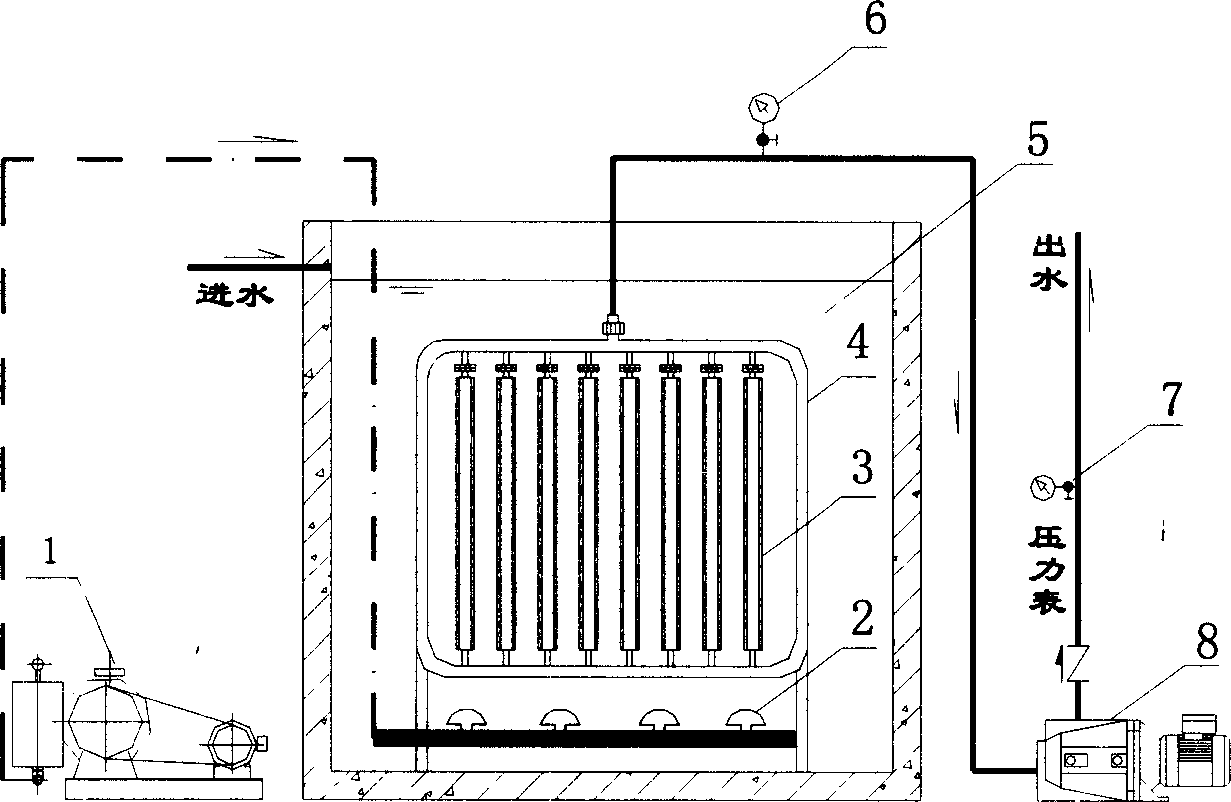

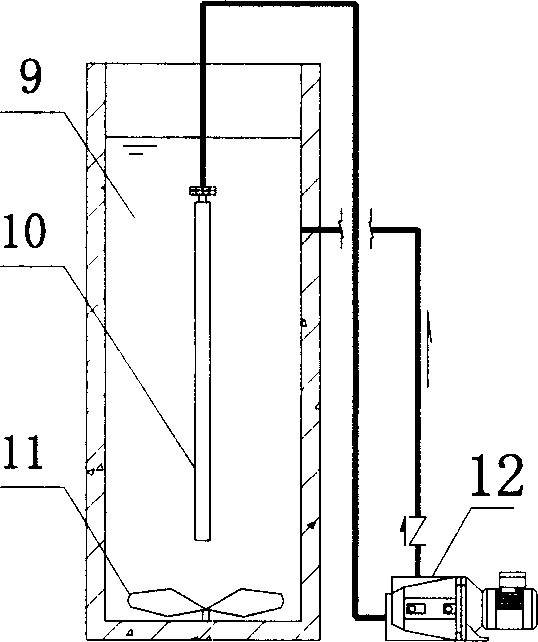

[0016] Treatment of domestic sewage water volume according to 45m 3 / d meter, COD concentration is 600mg / l. The flux of a single pre-coated dynamic membrane module is maintained at 80L / h m 2 , filter area is 3m 2 , with a single-sided area of 1.5m 2 , the specific dimensions are: height 1.5m, length 1.0m, then it is calculated that 8 filter components are required. Get a single filter assembly and place it in the pre-coating pool 9, which contains clear water and adds a pre-coating agent, which uses powdered activated carbon. The thickness of the pre-coating dynamic film is calculated as 1mm, so each filter module needs 3L of pre-coating agent. Turn on the mixer 11 to mix the pre-coating agent evenly, the suction pump 12 sucks the water out, and the water out circulates back to the pre-coating tank 9 . Circulate for 25 minutes to form a uniform pre-coated dynamic film on the surface of the filter assembly.

[0017] Eight pre-coated dynamic membrane modules 3 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com