Production method of corrugated wire

A processing method and corrugated technology, which is applied in the processing field of corrugated brush filaments, can solve problems such as indentation, uneven quality corrugation, poor straightness, etc., and achieve less waste, good quality, and convenient production and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

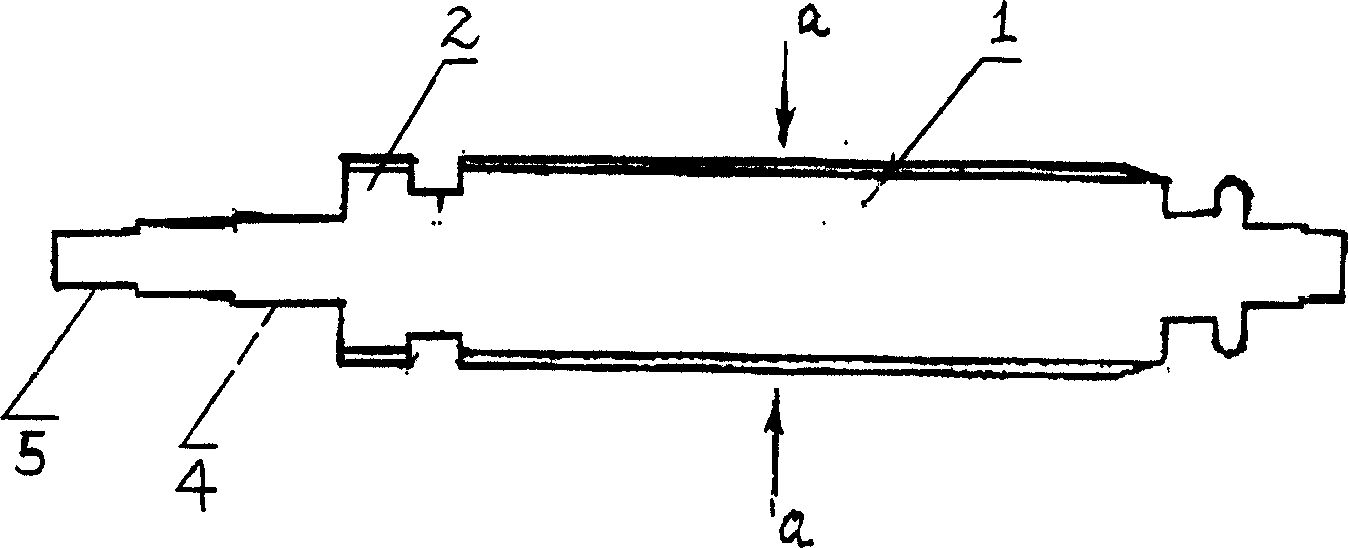

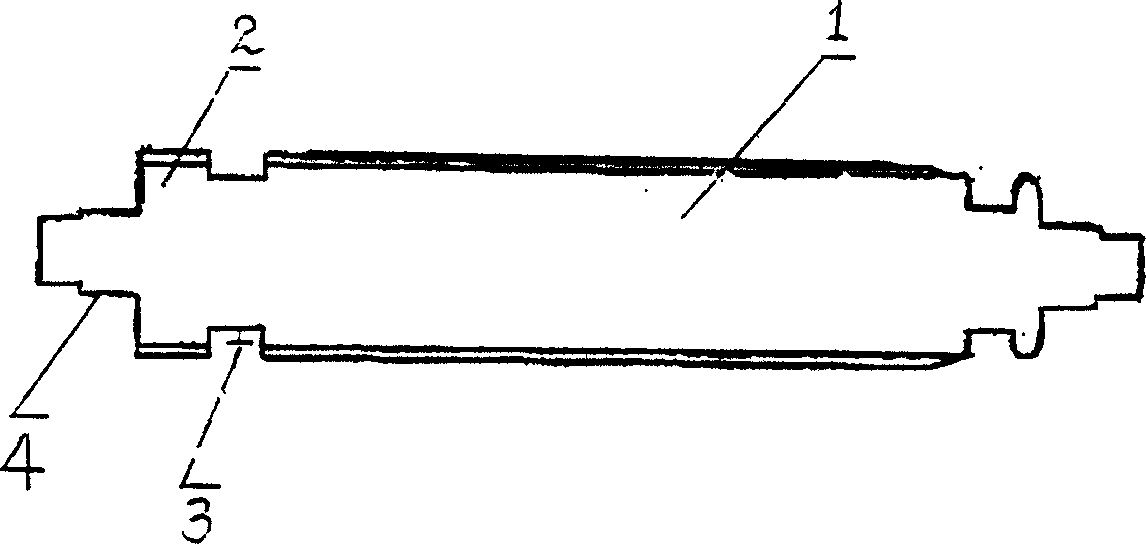

[0020] Select the gear hobbing machine according to the requirements, place the gear hobbing machine in front of the winding machine, and adjust the speed to make it consistent with the winding speed of the brush wire.

[0021] Pull the brush wire between the active hob and the passive hob, and adjust the height of the passive hob to a suitable position.

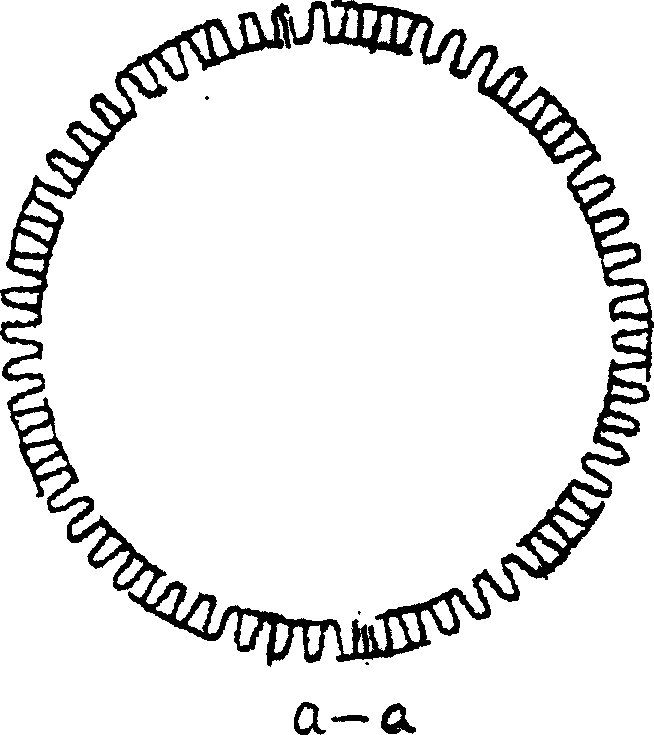

[0022] The tooth peaks are processed into a certain arc shape; the tooth pitch can be selected within the range of 1 inch 1.5 curvature - 1 inch 25 curvature in order to adjust the corrugation span. There is a certain gap between the teeth and the teeth in the kiss, and it is not easy to collide sharply with each other to interrupt the brush wire during transmission; the tooth depth range is between 4mm-10mm, and the corrugation effect is not obvious below 4mm, and the corrugation depth is higher than 10mm. It is easy to be crushed; the hobbing gear can be shifted up and down through the roller shaft; the electric speed regu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com