Light-emitting component capable of increasing light-emitting active area

A technology of light-emitting element and active area, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of reducing the amount of light output, light-emitting brightness, occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

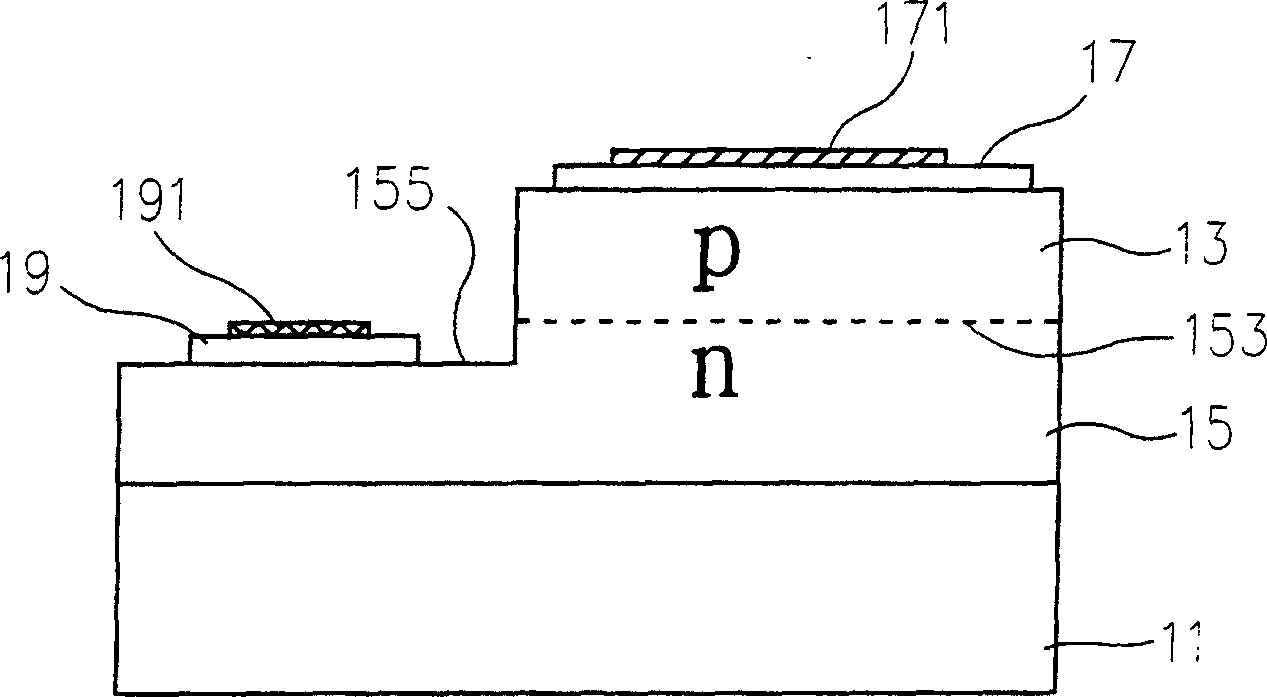

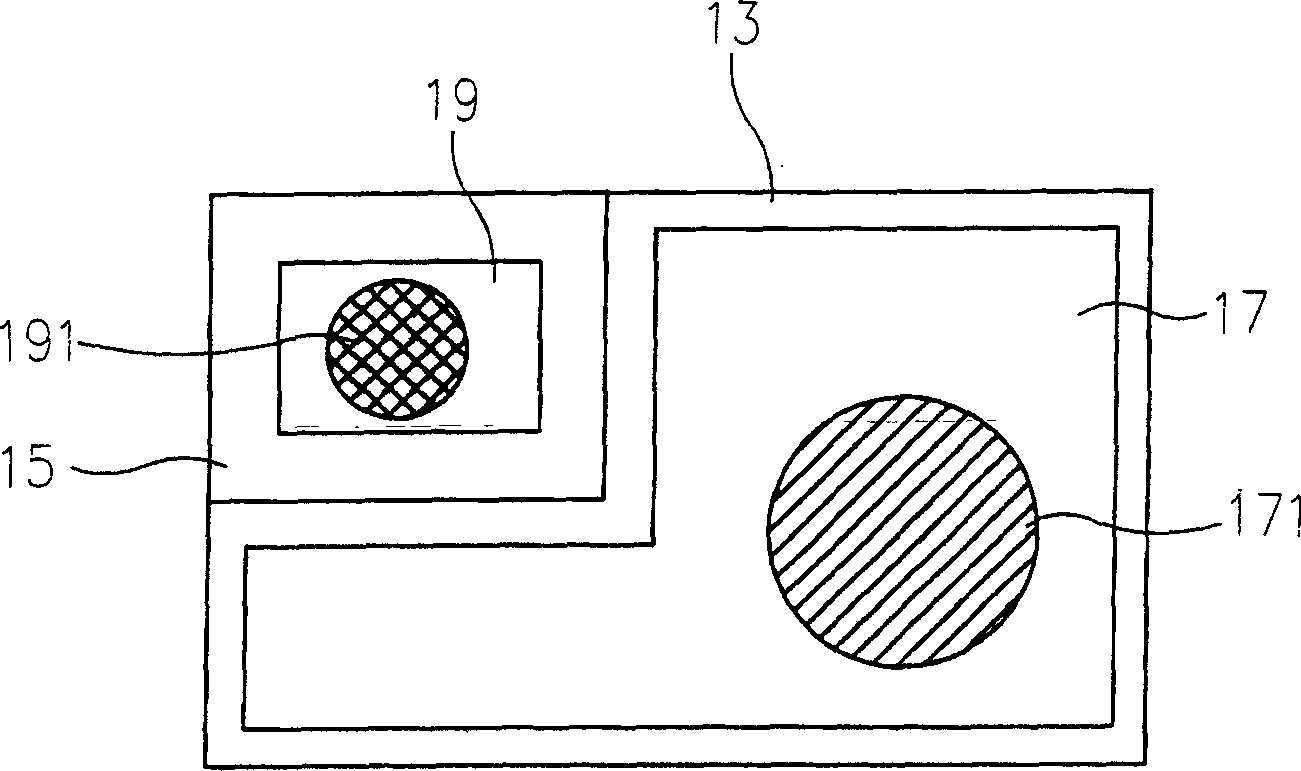

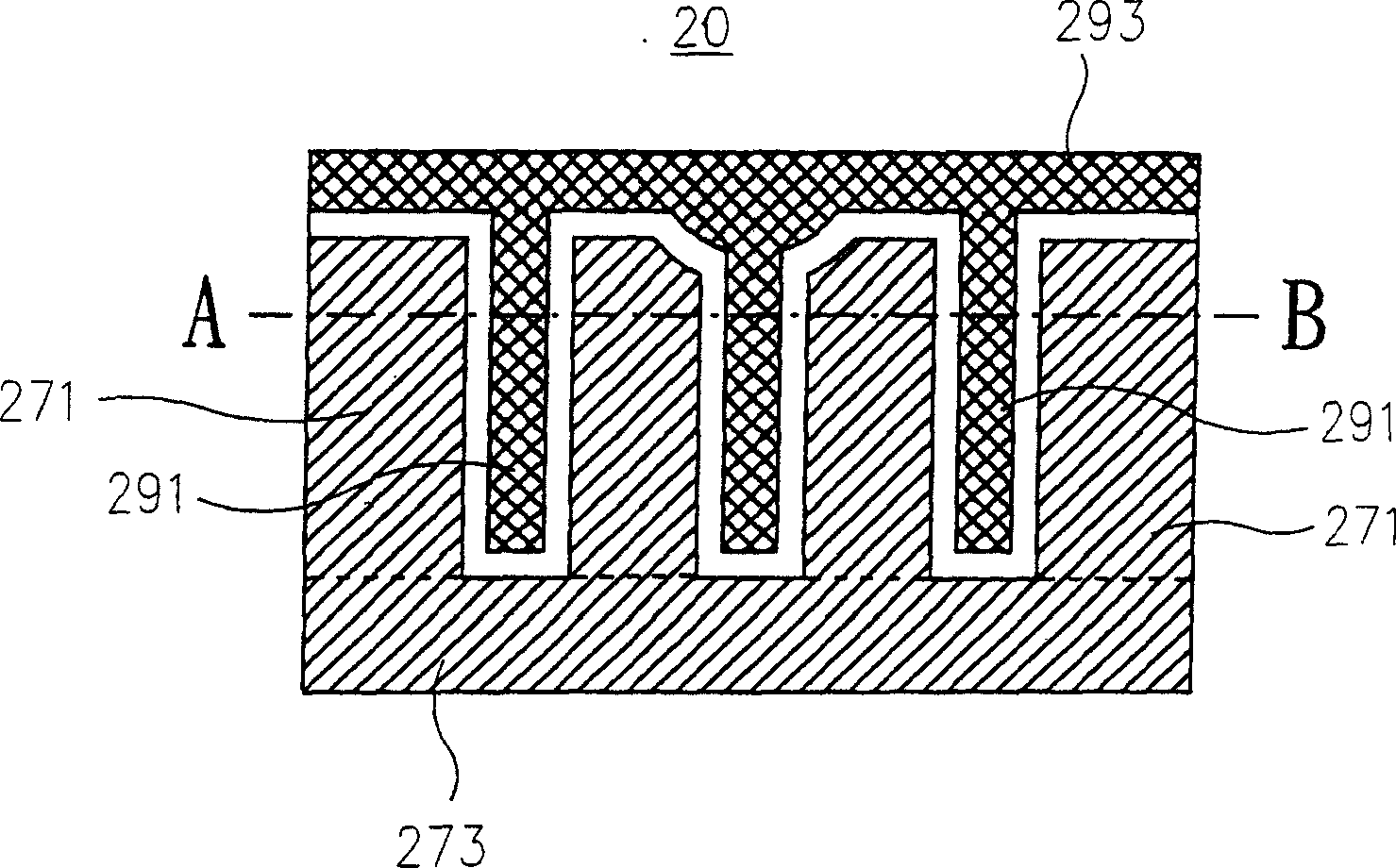

[0044] First, see Figure 3A to Figure 3C , are respectively a top view of the structure of a preferred embodiment of the present invention, a schematic cross-sectional view along line C-D, and a top view of the structure of the power supply substrate. As shown in the figure, the LED element that can increase the light-emitting active area is mainly composed of an LED chip 30 and a power supply substrate 41 . Wherein, the LED die 30 mainly forms a second epitaxial layer 35 on a die substrate 31, and the second epitaxial layer 35 can define a relatively convex first surface 353 and a relatively concave second surface. surface 355 , and a first epitaxial layer 33 is formed above the first surface 353 , so that a light-emitting region (namely the first surface 353 ) is naturally formed between the first epitaxial layer 33 and the second epitaxial layer 35 . Generally, the grain substrate 31 can be made of silicon carbide, gallium arsenide, sapphire, gallium nitride and other mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com