Multilayer winding device of continuous tube

A winding device and coiled tubing technology, applied in directional drilling, liquid/gas jet drilling, etc., can solve the problems of limited length of continuous steel pipes, difficult completion and implementation of ultra-deep drilling construction, etc., to reduce the limit, increase Effect of Winding Length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

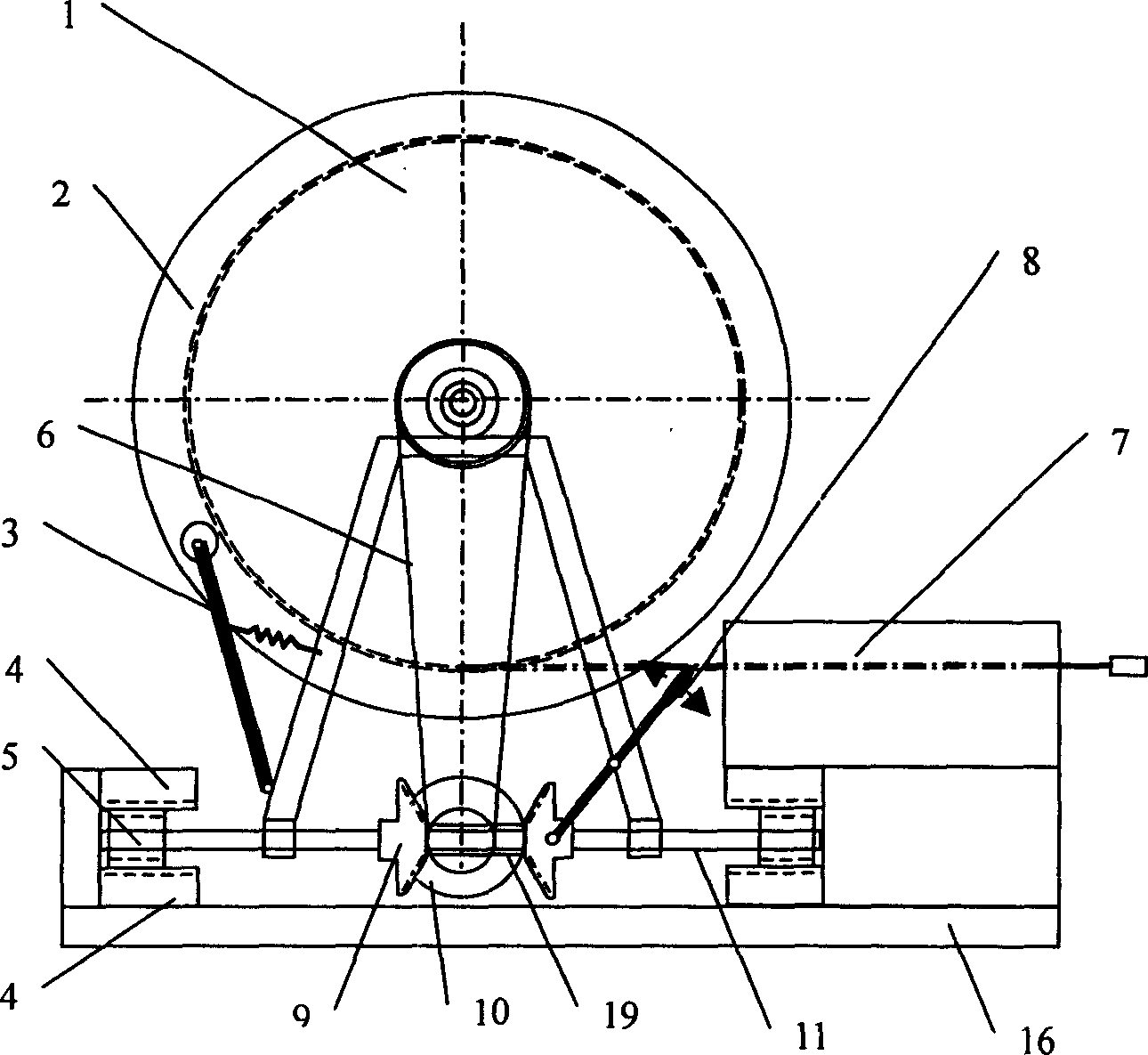

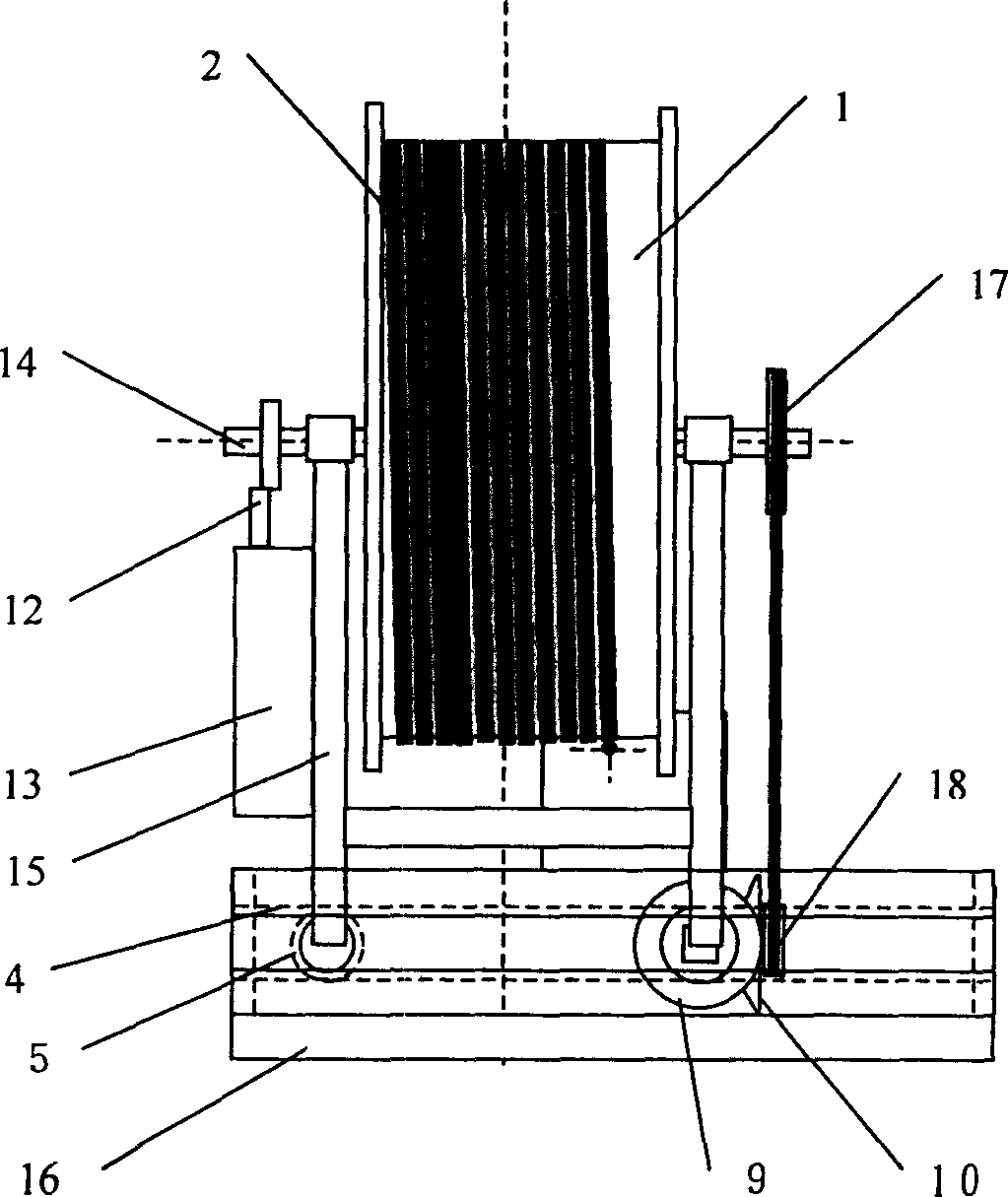

[0017] Such as figure 1 , 2 As shown, a multi-layer winding device for coiled tubing used in a "water jet continuous propulsion directional drilling rig" includes: a drilling rig base 16, a frame 15 connected to the base, and a drum 1 supported on the frame by a drum rotating shaft 14 , and steel pipe pressing mechanism 3, power mechanism 13. The drum rotating shaft 14 is connected with the power mechanism 13 through the drum driving clutch 12, the drum rotating shaft 14 and the drum 1 are connected with the frame drive shaft 11 through the transmission mechanism, and two traveling gears 5 are respectively fixed at both ends of the frame drive shaft 11. , and is mounted on a pair of racks 4 on the rig base 16 for meshing transmission to drive the frame 15 to move.

[0018] The transmission mechanism includes: the drum sprocket 17 is coaxially connected with the drum rotating shaft 14, and is transmitted through the chain 6 and the frame driving sprocket 18, the frame driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com