Method for preparing calcium phosphate series bioceramic nano-powder

A bio-ceramic and nano-powder technology is applied in the preparation of calcium phosphate-based bio-ceramic nano-powder and the field of calcium phosphate-based bio-ceramic nano-powder, which can solve the problems of unsatisfactory powder particle size and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The preparation method of the present invention is: according to the Ca / P molar ratio is 1.5-1.67 and takes the calculated amount of calcium nitrate Ca (NO 3 ) 2 4H 2 O and trimethyl phosphate (CH 3 O) 3 PO, dissolved in distilled water and alcohol respectively; then add citric acid C 6 h 8 o 7 After fully dissolving, mix the calcium nitrate aqueous solution and the trimethyl phosphate alcohol solution, adjust the pH of the mixture to 3-11 with ammonia water, and age at room temperature for 12-48 hours; then dry at 80-190°C for 2-10 hours to generate xerogels; and finally calcined at 500-600°C for 1-3 hours to obtain the required nano powder.

[0010] By controlling the Ca / P atomic ratio between 1.5 and 1.67, calcium phosphate-based bioceramic nanopowders, such as hydroxyapatite Ca 10 (PO 4 ) 6 (OH) 6 , Ca / P=1.67; β-tricalcium phosphate β-Ca 3 (PO 4 ) 2 , Ca / P=1.5; or a biphasic bioceramic composed of hydroxyapatite and β-tricalcium phosphate. In biphasic ...

Embodiment 1

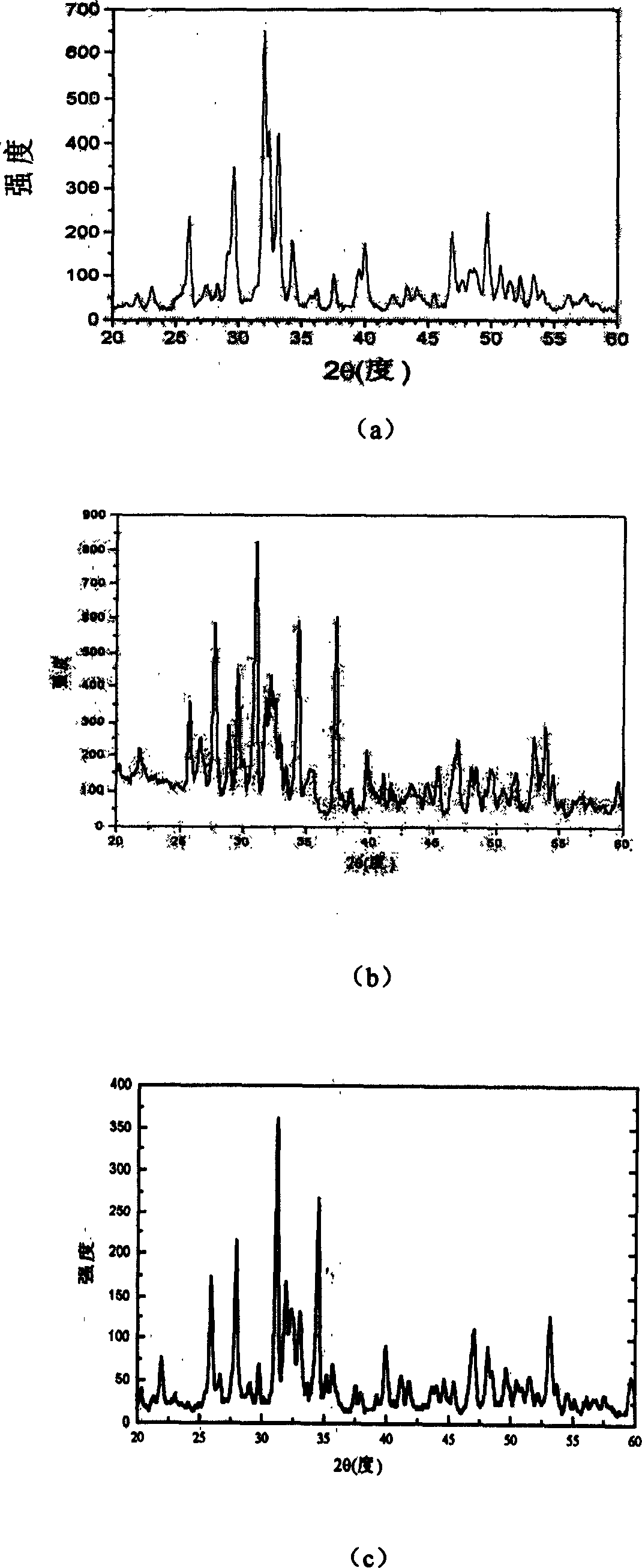

[0013] Weigh the calculated amount of calcium nitrate 19.706g (0.0835mol) and trimethyl phosphate 7.05g (0.05mol) according to the Ca / P molar ratio of 1.67, dissolve them with 80ml of distilled water and 30ml of alcohol respectively, and then add them to the calcium nitrate aqueous solution After fully dissolving 16.032g of citric acid in an equimolar amount with calcium ions, mix calcium nitrate aqueous solution and trimethyl phosphate alcohol solution, adjust the pH of the mixture to 7.5 with ammonia water, age at room temperature for 48 hours, and then at 190°C Drying at low temperature for 2 hours to form a xerogel, and finally calcining at 600°C for 1 hour to obtain the desired hydroxyapatite nanopowder. like figure 1 As shown in (a), X-ray diffraction XRD phase composition analysis shows that the main crystal phase of the prepared product is hydroxyapatite. figure 2 It is a transmission electron microscope TEM photograph of the hydroxyapatite nanopowder. It can be seen...

Embodiment 2

[0015] Weigh 17.7g (0.075mol) of calcium nitrate and 7.05g (0.05mol) of trimethyl phosphate according to the Ca / P molar ratio of 1.5, dissolve them in 80ml of distilled water and 30ml of alcohol, and then add them to the calcium nitrate aqueous solution. After fully dissolving 14.4g of citric acid with an equimolar amount of calcium ions, mix calcium nitrate aqueous solution and trimethyl phosphate alcohol solution, adjust the pH of the mixture to 11 with ammonia water, age at room temperature for 48 hours, and then dry at low temperature for 3 hours to form a xerogel, and finally calcined at 600°C for 2 hours to obtain the desired β-tricalcium phosphate nanopowder. like figure 1 As shown in (b), X-ray diffraction XRD phase composition analysis shows that the main crystal phase of the prepared product is β-tricalcium phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com