Slow corrosion bactiriocide

A fungicide and corrosion-inhibiting technology, used in biocides, animal repellents, plant growth regulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In a four-necked flask equipped with a thermometer and a reflux condenser, add 0.1 mol (47.6 g) of an ethoxyimidazoline compound, and under stirring, slowly add 0.1 mol (17.4 g) of benzyl bromide. , slowly heat up to 60~100 ℃, heat preservation reaction 6~8 hours, heat preservation is finished, add 20g imidazoline derivatives, 25g ethylene glycol, 45g water, can make the corrosion inhibitor and fungicide of the present invention.

[0038] Its use effect is as follows:

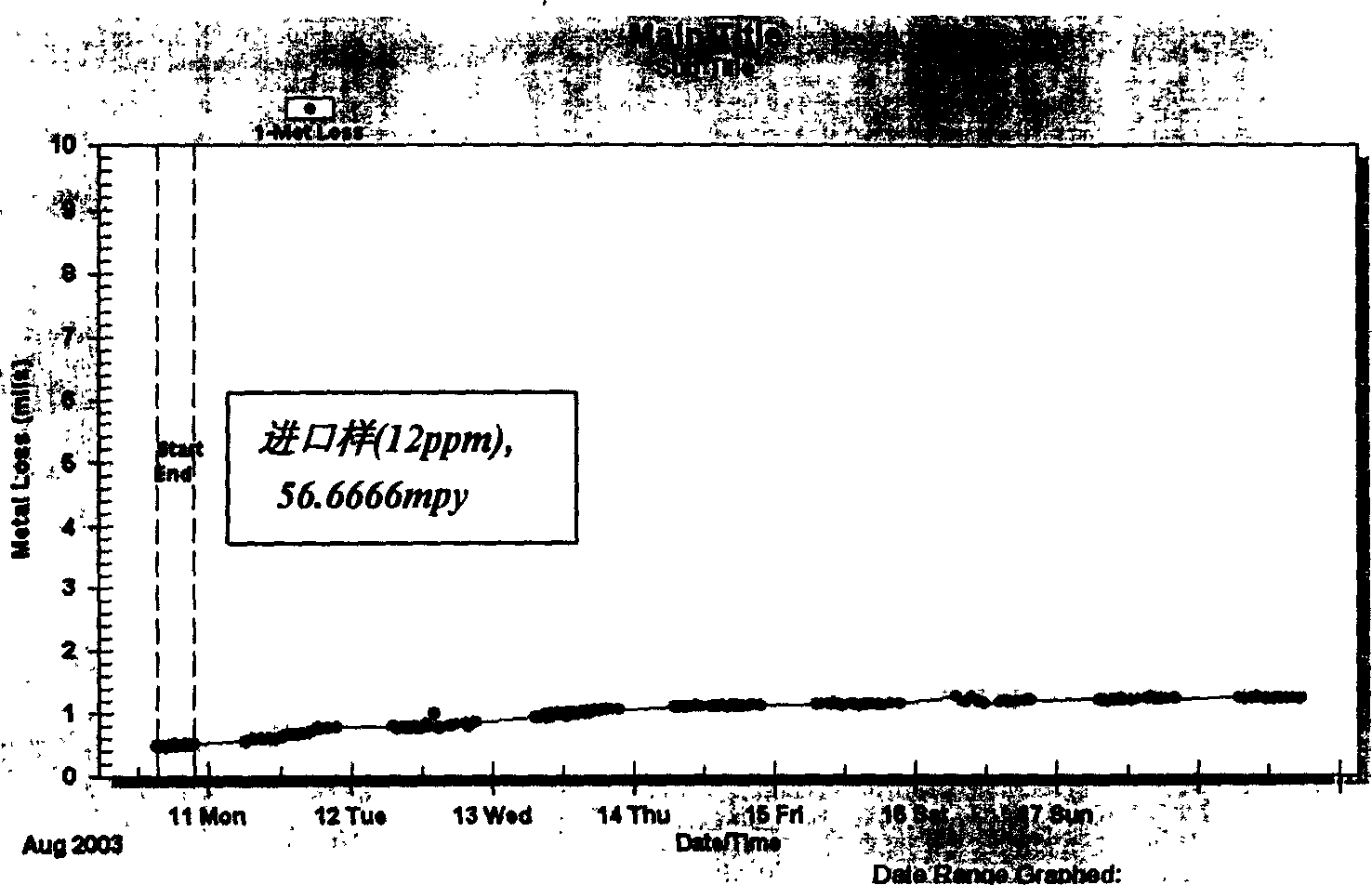

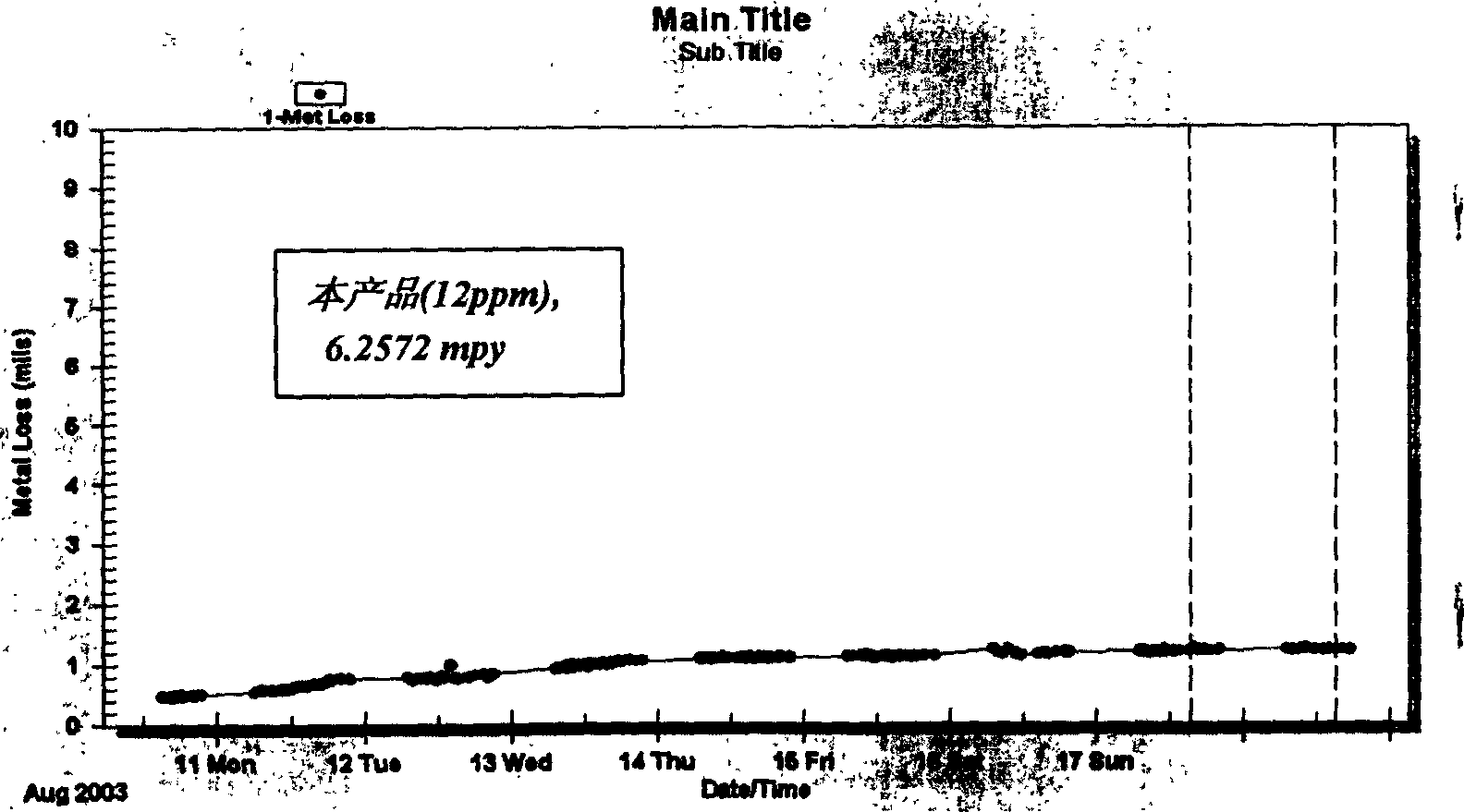

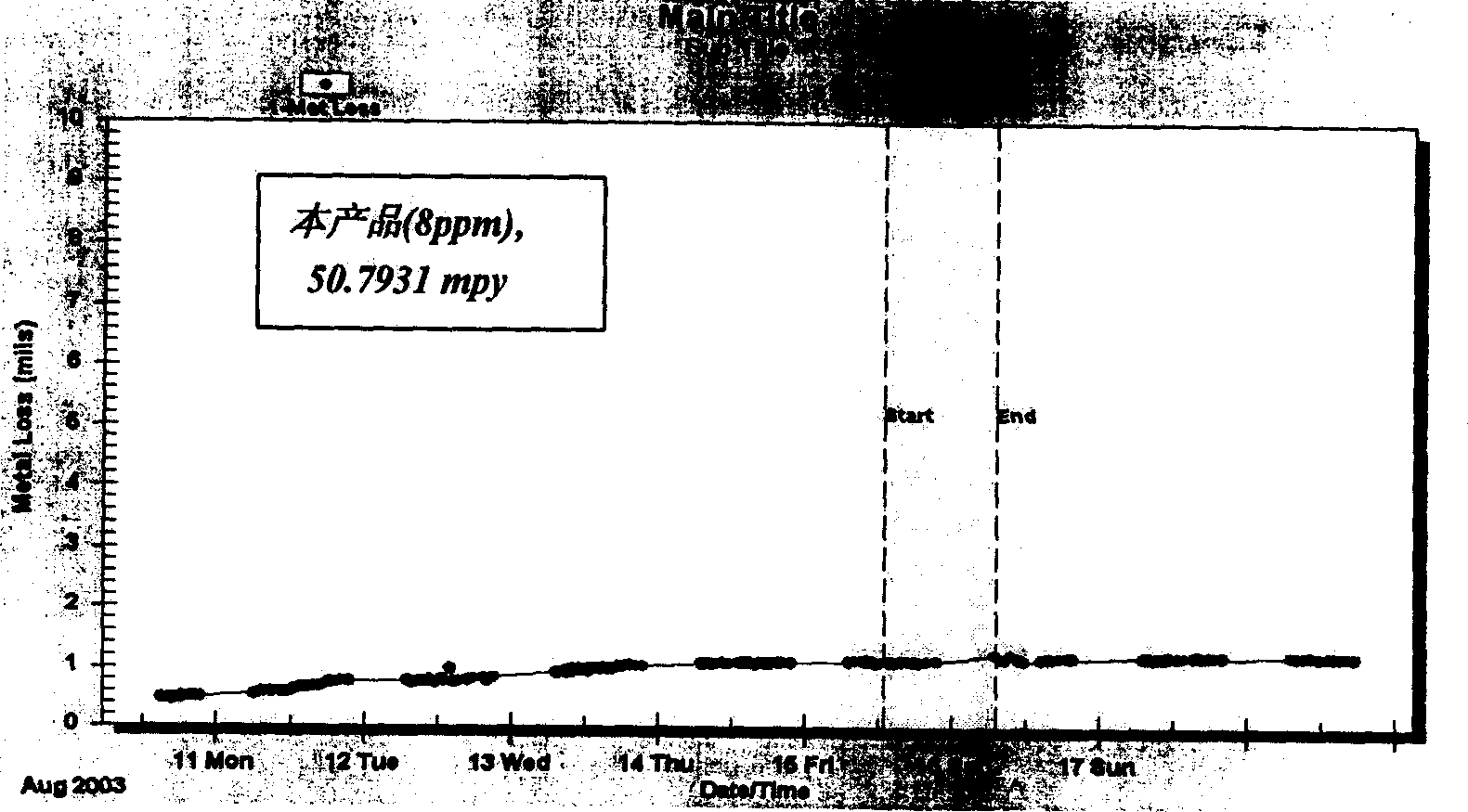

[0039] (1) Corrosion inhibition performance

[0040] Experimental conditions: oily sewage in an oilfield, supplemented with [S 2- ]: 50ppm;

[0041] Mounting time: 48 hours; temperature: 80°C; CO 2 Pressure: 0.04~0.06MPa.

[0042] Experimental method: weightlessness method.

[0043] Table 1 Corrosion inhibition effect of corrosion inhibitor and fungicide

[0044] Agent concentration Blank 20 30 50

[0045] (mg / L)

[0046] Corrosion rate 40.96 5.32 0.68 0.53

[0047] (mpy)

[...

Embodiment 2

[0057] 70 g of sodium acetate ethoxy imidazoline quaternary ammonium salt, 50 g of imidazoline derivatives, 60 g of ethylene glycol and 20 g of water are added to the reactor in sequence, and stirred for 20 to 30 minutes to prepare the corrosion inhibitor and bactericide of the present invention. The agent has a higher corrosion inhibition rate for acidic concentrated brine at a lower concentration. Its use effect is shown in Table 3.

[0058] Experimental conditions: [NaCl]: 5%; supplemented with [S 2- ]: 40ppm; CO 2 except O 2 And maintain; water temperature: 50 ℃; hanging time: 48 hours.

[0059] Experimental method: weightlessness method.

[0060] Table 3 Corrosion inhibition effect of different dosage of corrosion inhibitor and fungicide

[0061] Agent concentration 5 10 20 30 40 Blank

[0062] (mg / L)

[0063] Corrosion rate (mpy) 5.039 2.732 1.896 0.932 0.800 16.36

[0064] Corrosion inhibition rate (%) 69.2 83.3 88.4 94.3 95.1 -

[0065] Surfa...

Embodiment 3

[0067] 50g of benzylethoxyimidazoline quaternary ammonium salt, 50g of imidazoline derivatives, 40g of ethylene acetal, and 60g of water were added to the reactor in turn and stirred for 20-30 minutes. The product has excellent properties as a pickling corrosion inhibitor. Corrosion inhibition properties. The anti-HCl corrosion inhibition effect is shown in Table 4, and the anti-H 2 SO 4 The corrosion inhibition effect is shown in Table 5.

[0068] (1) Experimental conditions: sample preparation with tap water; [HCl]: 7%; water temperature: 50°C; mounting time: 12 hours.

[0069] Experimental method: weightlessness method.

[0070] Table 4 Corrosion inhibition and fungicide resistance to HCl pickling corrosion inhibition performance

[0071] Chemical name Corrosion inhibitor and fungicide Blank Foreign control sample

[0072] Drug concentration (%) 0.2 Blank 0.2

[0073] Corrosion rate (mpy) 31 2625 32

[0074] Corrosion Inhibition Rate (%) 98.8 - 98.8

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com