Method for preparing carbon coated nano metal material using biological material-starch as substrate

A biomaterial and nano-metal technology, applied in the petroleum industry, coke ovens, etc., can solve the problems of many by-products and complex processes, and achieve the effect of easy process, low equipment requirements, and easy parameter control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 2.00 g of soluble starch, add it to a small beaker (50 ml) containing 5 ml of deionized water, and stir it into a paste with a glass rod. Then weigh 0.10g Fe(NO 3 ) 3 9H 2 O and dissolve it in 50ml deionized water, then slowly add 0.1mol / L NaOH with a molar ratio of 3:1 to this solution to obtain Fe(OH) 3 Precipitation, the Fe(OH) 3 The precipitate was added to the starch paste obtained above, and the tan paste was obtained after being fully stirred, put into an oven and dried at 100°C for 2 hours, and the dried sample was ground into a fine powder with a mortar.

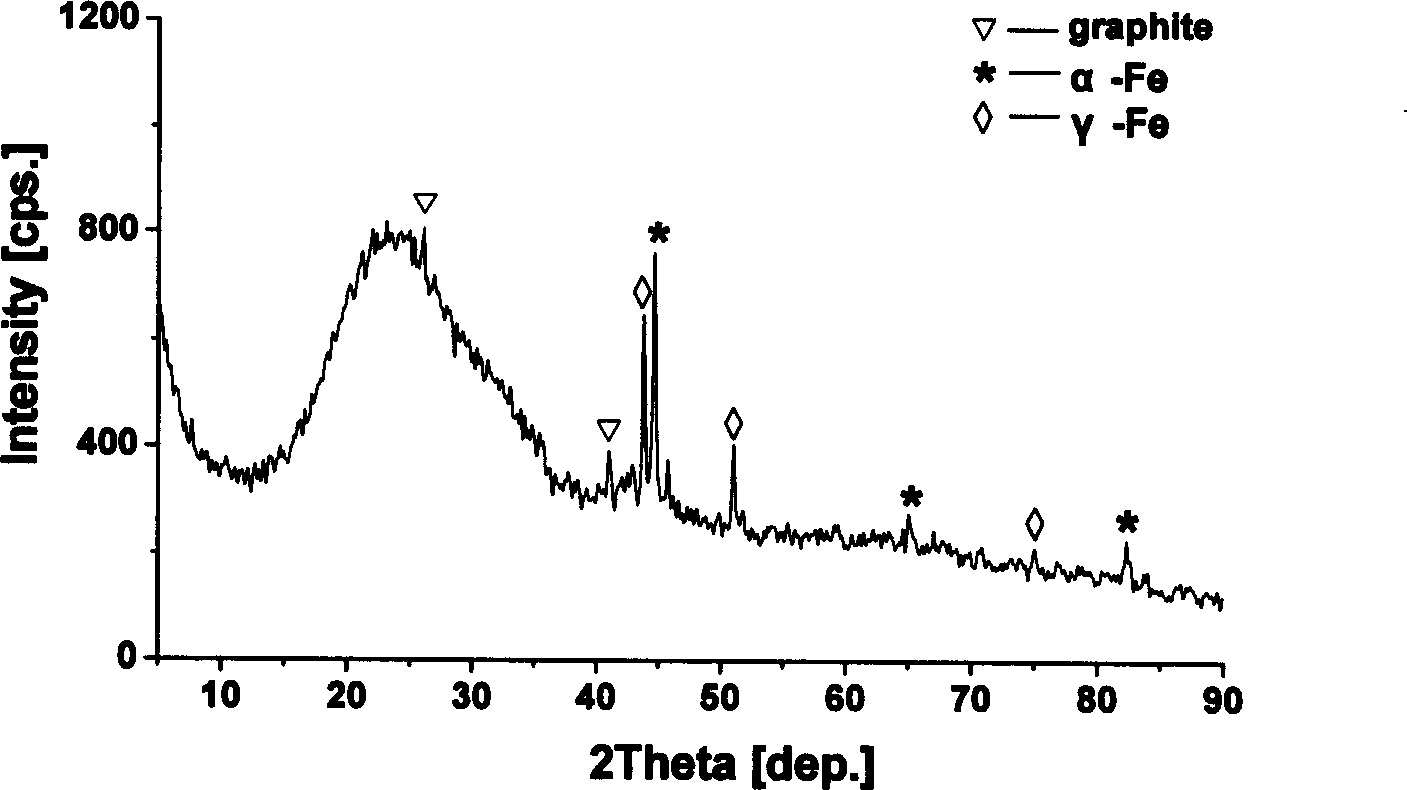

[0029] The above-mentioned fine powder of 1.00g is put into quartz boat, then places the center of the quartz reaction tube (diameter 30mm, length 600mm) in the tubular carbonization furnace; 3 / min rate into the reaction tube, and then at a rate of 5 °C / min, the carbonization furnace was heated to 900 °C and kept at a constant temperature for 4 hours. After the carbonization reaction, switch the h...

Embodiment 2

[0031] Weigh 20.00 g of soluble starch, add it into a small beaker (100 ml) containing 30 ml of deionized water, and stir it into a paste with a glass rod. Then weigh 1.00g Fe(NO 3 ) 3 9H 2 O and dissolve it in 50ml of deionized water, slowly add 0.1mol / L NaOH with a molar ratio of 3:1 into this solution to generate Fe(OH) 3 Precipitation, the Fe(OH)3 The precipitate was added to the above starch paste, and after being fully stirred to obtain a tan paste, it was put into an oven and dried at 100°C for 2 hours, and the dried sample was ground into a fine powder with a mortar.

[0032] Put 1.00 g of the above-mentioned fine powder into a quartz boat, then place it in the center of a quartz reaction tube (30 mm in diameter, 600 mm in length) in a tubular carbonization furnace, and then feed hydrogen into the reaction tube (20 cm 3 / min), then raise the temperature of the carbonization furnace to 300°C at a rate of 5°C / min, and keep the temperature constant for 1h, then heat th...

Embodiment 3

[0034] Weigh 20.00 g of soluble starch, add it into a small beaker (100 ml) containing 30 ml of deionized water, and stir it into a paste with a glass rod. Then weigh 1.00g Fe(NO 3 ) 3 9H 2 O, join in 50ml of deionized water, then slowly add 0.1mol / L NaOH with a molar ratio of 3:1 to generate Fe(OH) 3 Precipitation, the Fe(OH) 3 The precipitate was added to the above starch paste, and the tan paste was obtained after being fully stirred, and dried in an oven at 100°C for 2 hours, and the dried sample was ground into a fine powder with a mortar.

[0035] 2.00 g of the above fine powder was put into a quartz boat, and then placed in the center of a quartz reaction tube (diameter 30 mm, length 600 mm) in a tubular carbonization furnace. Then the hydrogen was injected at 20cm 3 The flow rate of / min is passed into the reaction tube, and the temperature of the carbonization furnace is raised to 900°C at a rate of 7.5°C / min and kept at a constant temperature for 4 hours; 3 / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com