High-temperature slap discharging valves

A slag discharge valve, high temperature technology, applied in sliding valves, valve devices, combustion methods, etc., can solve problems such as poor high temperature resistance, performance failure, slag material sticking and jamming, and achieve low price and increased reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

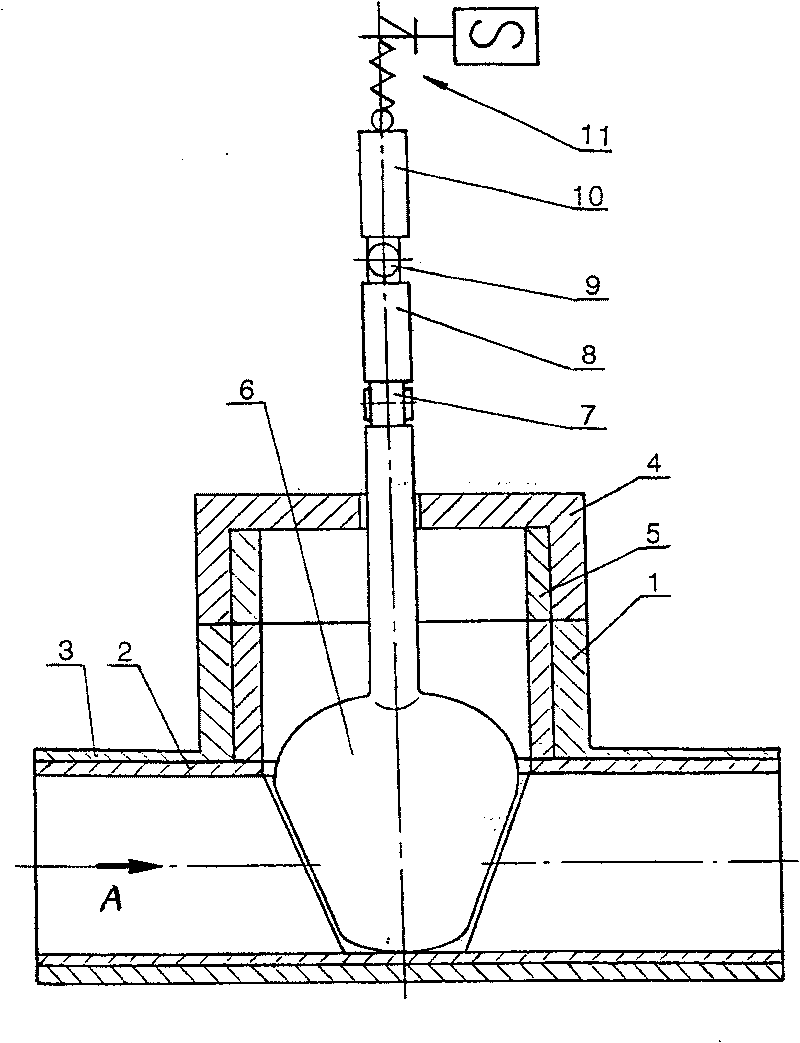

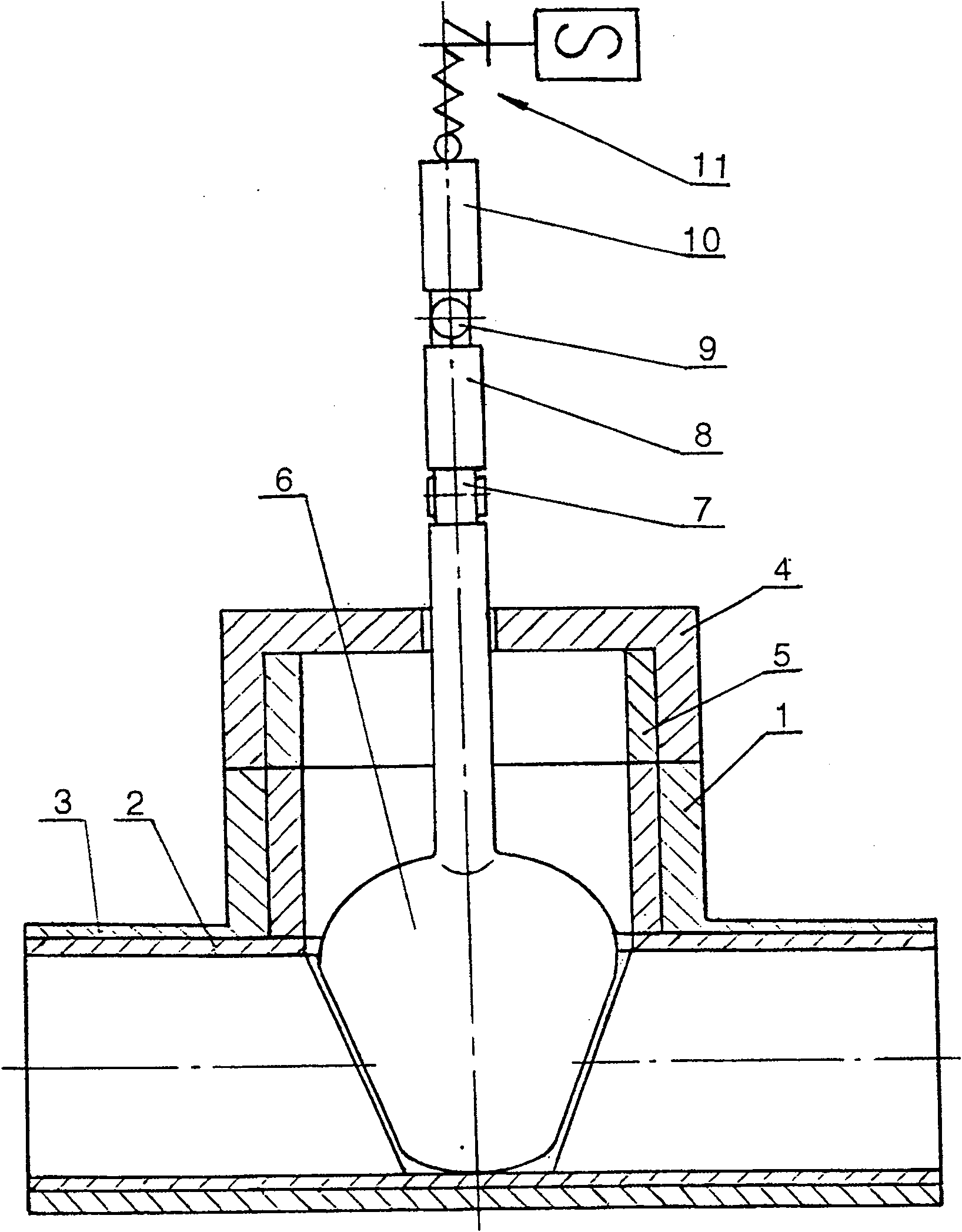

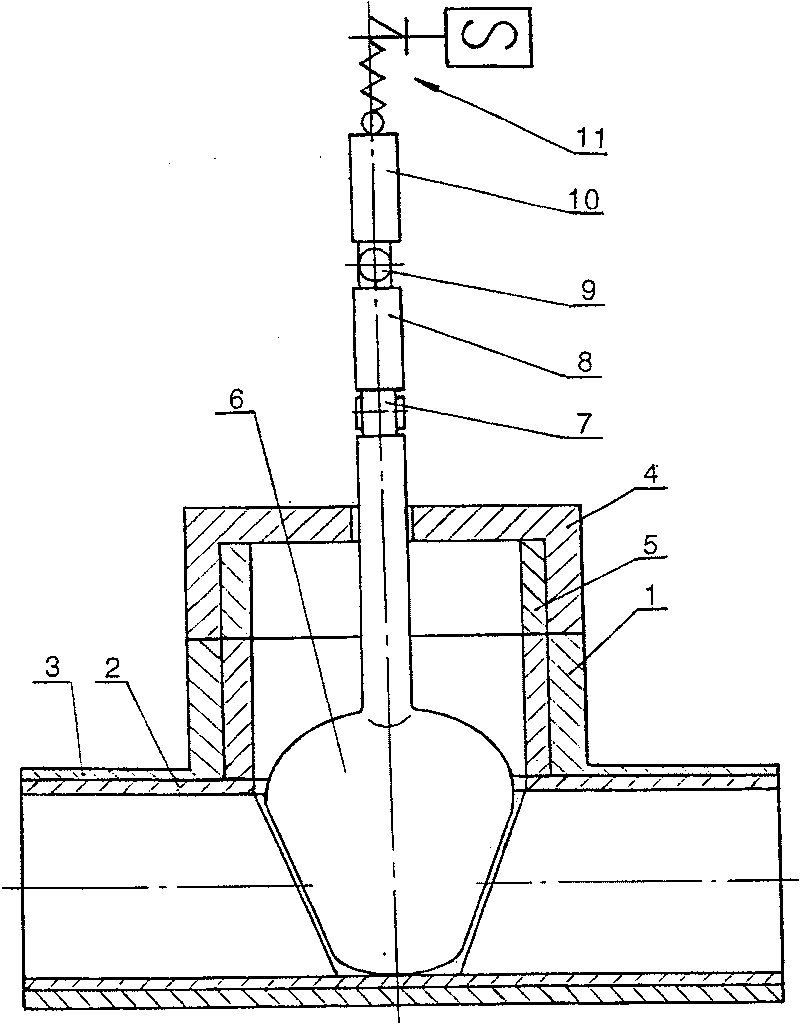

[0066] An embodiment structure of a high temperature slag discharge valve is as follows: a valve body 1 is provided with a vertical upward opening and two horizontal end openings, the valve body 1 has an inner layer 2 and an outer layer 3; The top of 1 is equipped with a bonnet 4, and the inner wall of the bonnet 4 is provided with a bonnet inner layer 5; a valve core 6 is installed in the cavity formed by the valve body 1 and the bonnet 4, and the spool 6 has an elliptical cone shape. The head and a core rod, the upper end of the core rod is connected with a heat-resistant connecting rod 8 through a universal joint 7, and the latter is connected with another heat-resistant connecting rod 10 through another universal joint 9. The upper end of the connecting rod 10 is connected with the power transmission device 11 which can be rotated and lifted.

[0067] The production process of the high temperature slag discharge valve is as follows:

[0068] (1) Valve body 1 and bonnet 4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com