Making process of spherical porous coaly biological filtering material for processing waste water

A technology for biological filter material and wastewater treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problems of high energy consumption, secondary pollution, no ceramsite quality indicators, etc. Achieve the effect of small bulk density, high specific surface area, and solving the problem of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

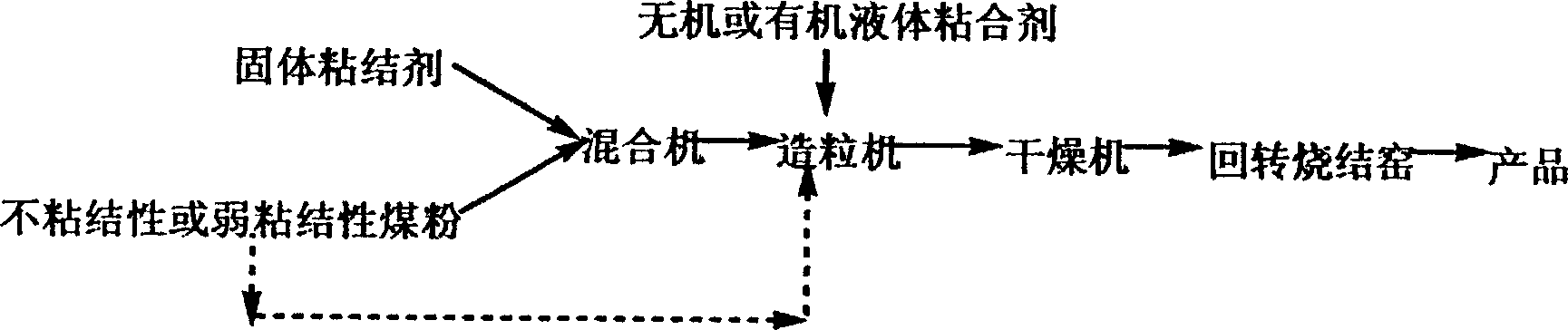

Method used

Image

Examples

Embodiment 1

[0021] The proportioning of embodiment 1 is: pulverized coal 900g, lime 50g, polyvinyl formal 50g.

[0022] The operation method of embodiment 1:

[0023] 1. Add 900g of raw coal powder and 50g of lime powder into the mixing kettle and mix for 10 minutes. Then add 200g of water and mix for 10 minutes, then add 50g of polyvinyl formal and mix for 10 minutes. Artificial granulation.

[0024] 2. Put the pellets into a muffle furnace with a temperature of 100°C for 60 minutes to keep warm and dry, then raise the temperature to 450°C for sintering for 90 minutes.

[0025] 3. The sintered coal-based biological filter material is naturally cooled to room temperature after being discharged from the furnace.

[0026] The proportion of Example 1 is shown in Scheme 1 in Table 1, which is a scheme in which a composite of an inorganic solid and an organic liquid binder is used as a binder. The product quality after sintering is shown in Scheme 1 in Table 2. The difference between embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com