Preparation method of nanometer modified corona-tolerant enamel of enameled wire

A wire enamel and nano-modification technology, which is applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve problems such as difficult dispersion, improve dispersion state, improve flexibility and adhesion, and store stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method for nano-modified corona-resistant wire enamel, comprising the following steps:

[0053] (1) dispersion of nanomaterials: get 14 parts (weight, the same afterward) nano-titanium oxide, add 70 parts of organic solvents (cresol: dehydrated alcohol=6: 4), adopt the method for high-speed shearing to make inorganic oxidation at room temperature The substance is dispersed to a uniform nano-dispersion state;

[0054] (2) Nanomaterial modification: Add 0.6 parts of modifier KH550 and react at 120°C for 1.5 hours to obtain modified nanomaterial slurry emulsion;

[0055] (3) Preparation of nanomaterial / insulating resin composite: Add 100 parts of DF-127 polyesterimide resin (40% solid content) into the modified nanomaterial slurry, heat to 120°C, and keep warm at 120°C for 2.0 Hour;

[0056] (4) Preparation of corona-resistant wire enamel: then lower the temperature to 70°C, add various additives required for wire enamel (consistent with the composition, do...

Embodiment 2

[0059] (1) The composition of the nanoparticles is 1.75 parts of nano-zinc oxide, 0.7 parts of nano-silicon-based oxide, and 11.55 parts of nano-titanium oxide. The rest are the same as in Example 1 and omitted.

[0060] (2) The prepared varnish was coated with a three-layer composite magnet wire according to the method of the comparative example.

[0061] (3) Use the paint prepared in Example 2 as the middle layer paint, and coat the double-layer composite magnet wire according to the method of Comparative Example 2.

[0062] The technical indicators of the corona-resistant electromagnetic wire varnish prepared by comparative example 2, embodiment 1, 2 are as follows:

[0063] Viscosity: 20℃, 500~800mPa·s

[0064] Solid content: 1.0g sample, 200℃, 1.0h, ≥35%

[0065] 2. Coating of corona-resistant magnet wire

[0066] Coating equipment: Italian SICME SEL-SP horizontal coating testing machine,

[0067] Austria MAG VN6 / 2H vertical wire coating machine.

[0068] Furnace tem...

Embodiment 3

[0080] A preparation method for nano-modified corona-resistant wire enamel, comprising the following steps:

[0081] (1) dispersion of nanomaterials: get 20 parts (weight, the same below) of nano-alumina, add 100 parts of organic solvent (cresol: dehydrated alcohol=1: 1), adopt the method for high-speed shearing to make inorganic oxidation at room temperature The substance is dispersed to a uniform nano-dispersion state;

[0082] (2) Nanomaterial modification: add 1.0 parts of modifier KH560, and react at 140°C for 3 hours to obtain a modified nanomaterial slurry emulsion;

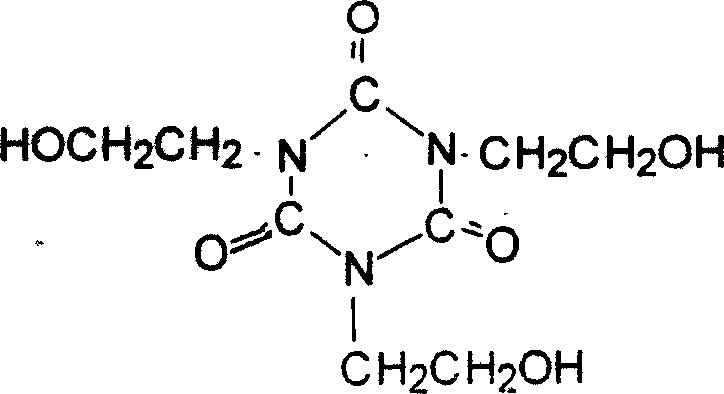

[0083] (3) Preparation of nanomaterial / insulating resin composite: add 100 parts of trihydroxyethylisocyanate-modified polyesterimide resin (40% solid content) into the modified nanomaterial slurry, heat to 120°C, Incubate at 120°C for 6 hours;

[0084] (4) Preparation of corona-resistant wire enamel: then lower the temperature to 70°C, add various additives required for wire enamel (consistent with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com