Process for preparing titanium dioxide film on metal Ti surface and Ti plate with titanium dioxide film coated surface prepared thereby

A technology of titanium dioxide and nano-titanium dioxide, which is applied in chemical instruments and methods, catalyst activation/preparation, metal material coating technology, etc., can solve the problems of titanium dioxide grain growth and specific surface area reduction, and achieve good crystallization and low cost , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of pure anatase crystal nano-titanium dioxide film on the surface of titanium sheet

[0056] The size of step 1 is 5×5×0.01(cm 3 ) The surface of the metal titanium plate is pickled with 10% (mass percentage) HF acid at room temperature, and then cleaned with water;

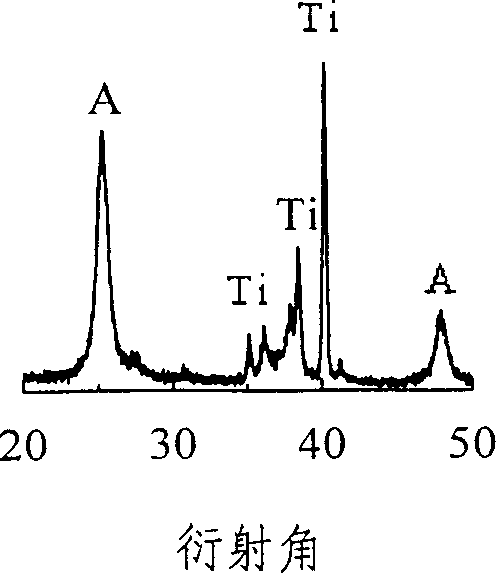

[0057] Step 2: immerse in 50 ml of 30% (mass percent) hydrogen peroxide solution, and react at 80° C. for 72 hours. Reaction result: The surface of the titanium plate uniformly produces a pure anatase crystal nanometer with a thickness of about 3 μm (calculated according to Table 1, and using a scanning electron microscope to observe and measure the morphology, the following examples are the same), and a grain size of about 10 nm. Titanium dioxide film (see figure 1 and 2 ). At the same time, about 37.7 mg of uniform titania nanorods with a diameter of about 20 nm and a length of about 100 nm were precipitated in the solution.

[0058] Table 1: Theoretical calculation...

Embodiment 2

[0077] Embodiment 2: Preparation of pure anatase crystal nano-titanium dioxide film on the surface of titanium sheet

[0078] The size of step 1 is 5×5×0.01(cm 3 ) The surface of the metal titanium plate is pickled with 10% (mass percentage) HF acid at room temperature, and then cleaned with water;

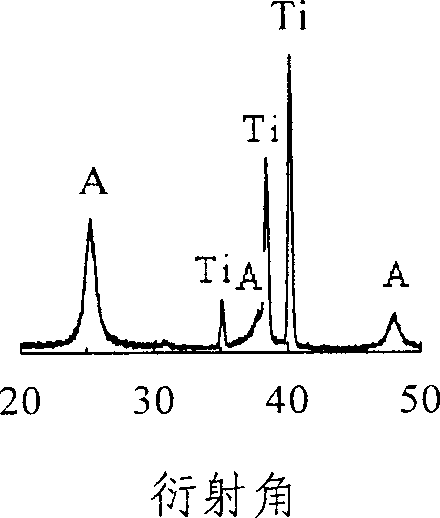

[0079] Step 2: immerse in 50 ml of 30% (mass percent) hydrogen peroxide solution, react at 80° C. for 48 hours, and prepare a titanium sheet covered with a pure anatase crystal nano-titanium dioxide film on the surface. The film grain size is about 10 nm, see image 3 .

Embodiment 3

[0080] Example 3: Preparation of pure anatase crystal nano-titanium dioxide film on the surface of titanium sheet

[0081] The size of step 1 is 5×5×0.01(cm 3 ) The surface of the metal titanium plate is pickled with 10% (mass percentage) HF acid at room temperature, and then cleaned with water;

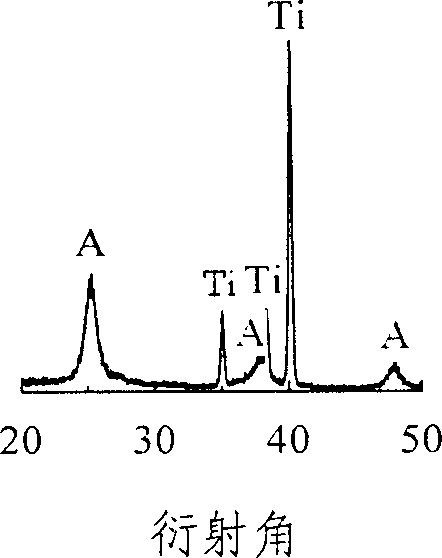

[0082] Step 2: immerse in 50 ml of 30% (mass percent) hydrogen peroxide solution, react at 80° C. for 24 hours, and prepare a titanium sheet covered with a pure anatase crystal nano-titanium dioxide film on the surface. The film grain size is about 10 nm, see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com