Urushi polysaccharide extracting method

A technology of raw lacquer and polysaccharides, which is applied in the field of extracting natural lacquer polysaccharides that can inhibit tumors. It can solve the problems of being unsuitable for mass production, poor separation and purification efficiency, and troublesome grading operations, and achieves low cost, inhibition of biological activity, and good purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

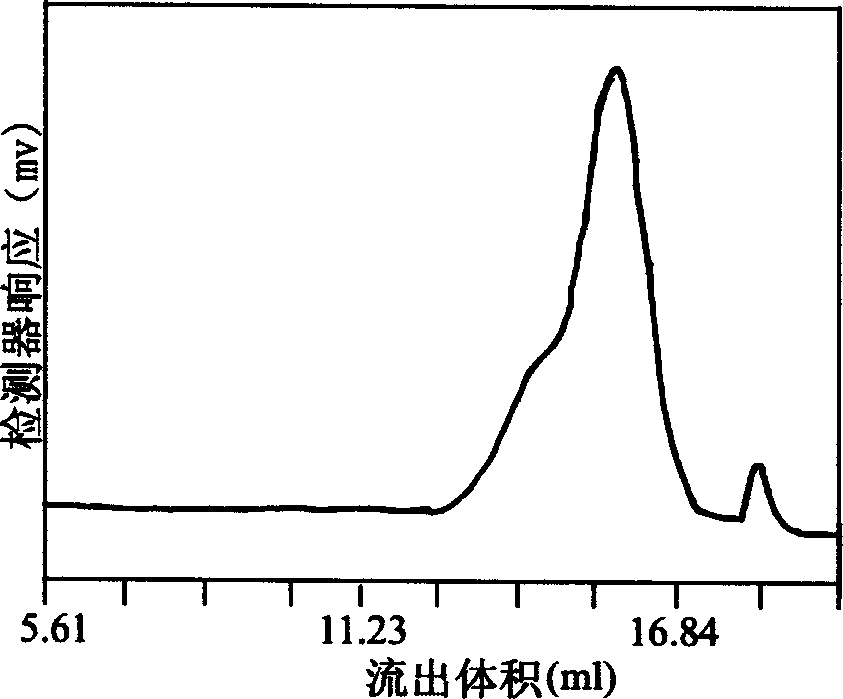

[0015] Example 1: Add 5 times the amount of acetone to 1kg sumac sap to soak and fully stir. After standing still, polysaccharides and glycoproteins, etc. will precipitate out with gray powder, pour off the black acetone solution, and repeatedly wash the precipitate with acetone several times until the acetone washes out Nearly colorless. The acetone solution was removed by suction filtration, and the precipitate was quickly dried at room temperature to obtain 102 g of gray acetone powder. Add appropriate amount of distilled water to acetone powder, stir overnight, centrifuge and filter to remove insoluble matter. Filtrate plus (NH 4 ) 2 SO 4 To saturation, after standing still for a period of time, centrifuge and suction filter to remove the precipitate, the filtrate is desalted by ultrafiltration with 3kDa membrane, and then concentrated by rotary evaporation at 50°C under reduced pressure, then add absolute ethanol to precipitate the polysaccharide, P 2 o 5 Vacuum-drie...

Embodiment 2

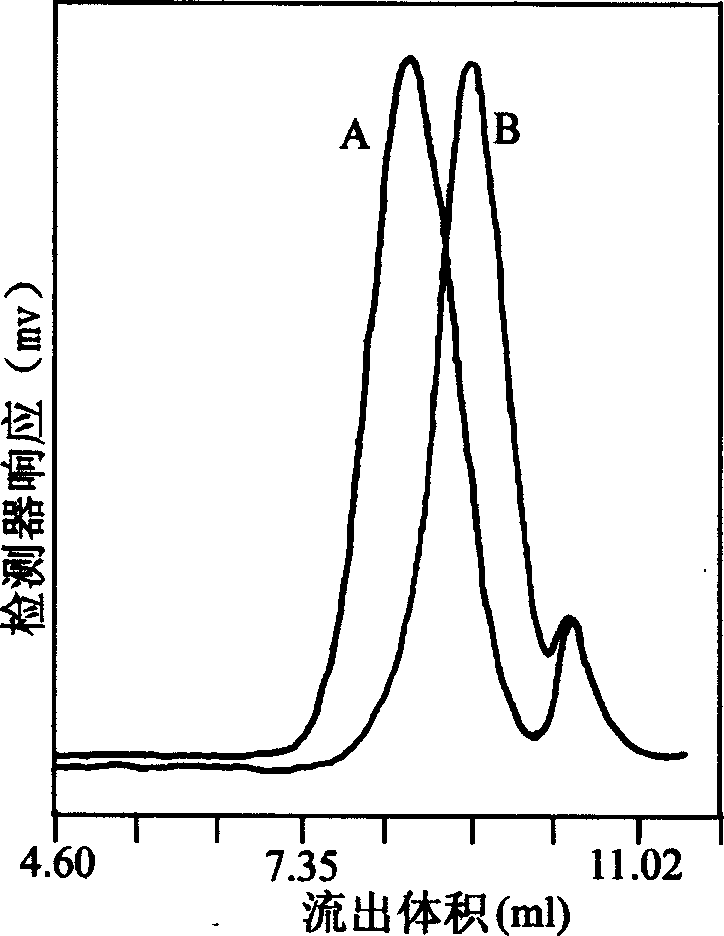

[0017] Example 2: Add appropriate amount of distilled water to the above acetone powder, add ammonium sulfate to 30% (w / w), stir overnight, then centrifuge and suction filter to remove insoluble matter. The filtrate was desalinized with a 3kDa membrane ultrafiltration, and passed through 732 (H + Type) cation exchange resin column, flow rate 10-15ml / h, phenol-sulfuric acid method to detect and collect the polysaccharide solution, neutralize it with dilute NaON solution to pH6-7, use 3kDa membrane ultrafiltration to concentrate the solution, and then concentrate under reduced pressure below 50°C , ethanol precipitation, P 2 o 5 The pure lacquer polysaccharide was obtained by vacuum drying with a yield of 5.44%.

Embodiment 3

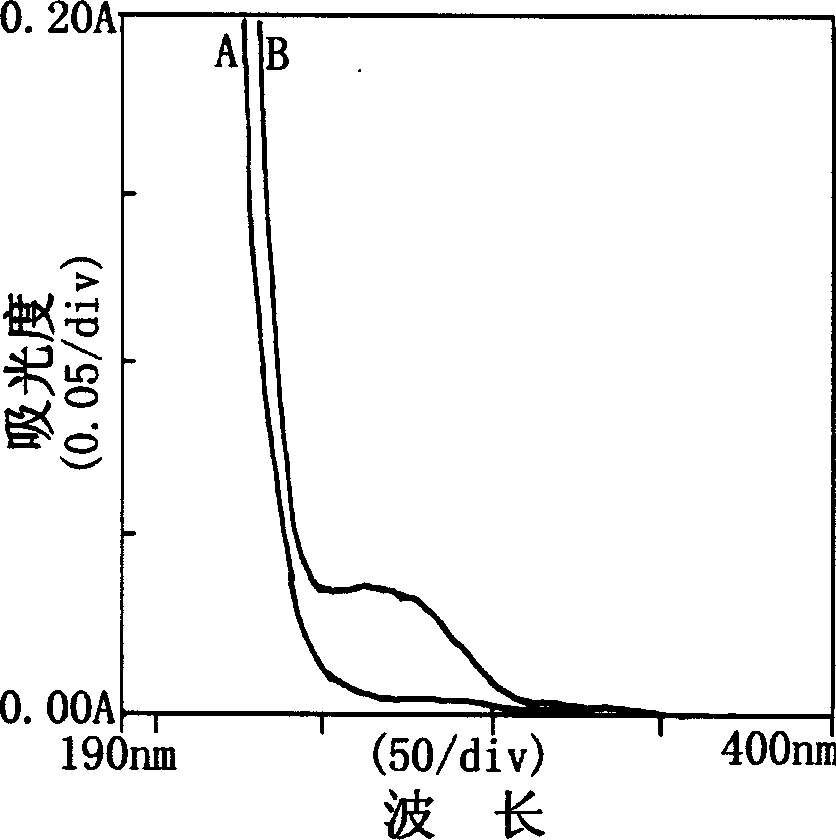

[0018] Example 3: Add an appropriate amount of distilled water to the above acetone powder, add ammonium sulfate to saturation, stir overnight, centrifuge and filter to remove insoluble matter. The filtrate was desalinized with a 3kDa membrane ultrafiltration, and passed through 732 (H + Type) cation exchange resin column, flow rate 30-45ml / h, phenol-sulfuric acid method to detect and collect polysaccharide solution, neutralize to pH6-7 with dilute NaON solution, concentrate the solution with 3kDa membrane ultrafiltration, and then concentrate under reduced pressure below 50°C , ethanol precipitation, P 2 o 5 The pure lacquer polysaccharide A was obtained by vacuum drying with a yield of 6.56%. The water-soluble glycoprotein absorption peak at 230-270nm in the pure polysaccharide UV spectrum disappears (attached figure 1 ), indicating a high purity polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com