R-T-B system rare earth permanent magnet

A permanent magnet, R-T-B technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of good magnetization characteristics and achieve the effect of improving magnetization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0120] Raw material alloys (low-R alloys and high-R alloys) having the composition shown in FIG. 1 were produced by strip casting.

[0121] Each of the obtained raw material alloys was allowed to store hydrogen at room temperature, and then dehydrogenated in an Ar atmosphere at 600° C. for 1 hour to perform a hydrogen pulverization treatment.

[0122] In order to obtain high magnetic properties, the oxygen content of the sintered body was controlled below 1000ppm in Experimental Example 1, so the protective atmosphere in each process from hydrogen pulverization (recovery after pulverization treatment) to sintering (putting into the sintering furnace) was controlled to be insufficient Oxygen concentration of 100 ppm (this point is also the same in Experimental Examples 2 to 11 below).

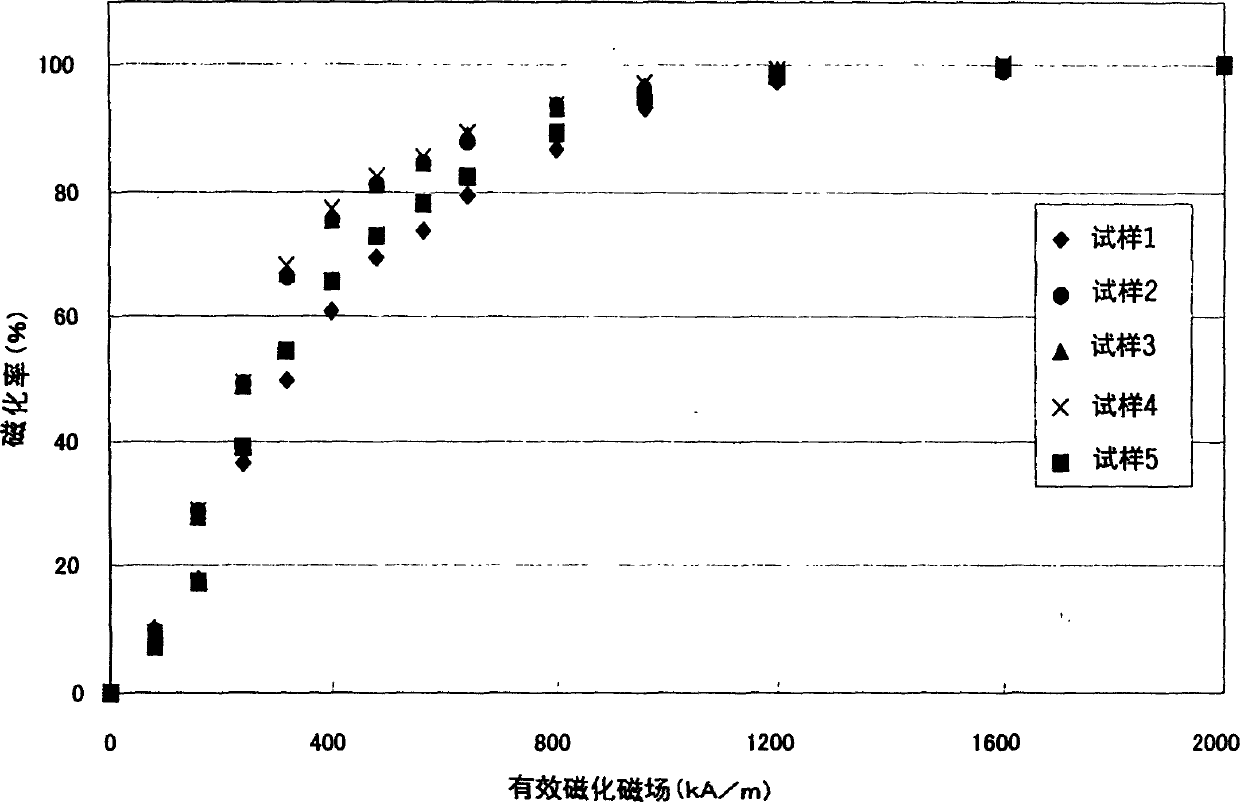

[0123] Generally, two-stage pulverization of coarse pulverization and fine pulverization is performed, and the coarse pulverization step was omitted in Experimental Example 1 (the same applies t...

experiment example 2

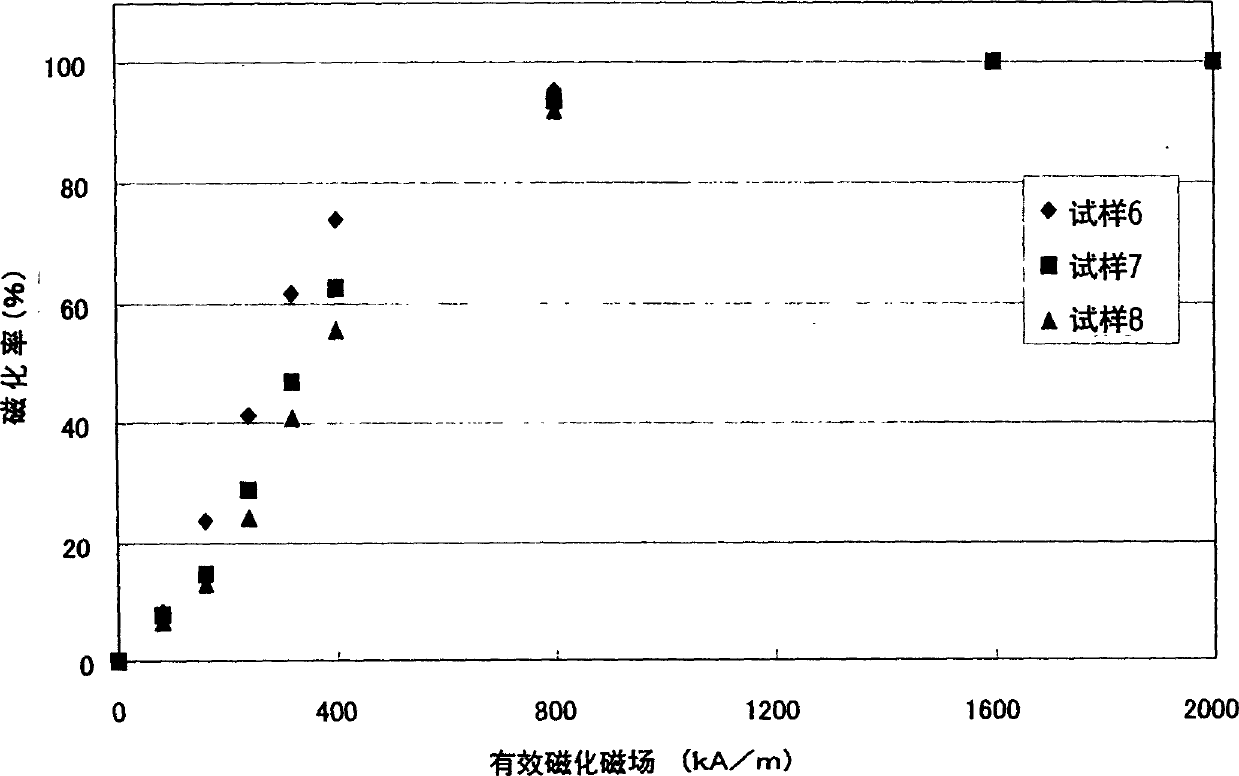

[0133] By using the raw material alloy of the composition shown in Figure 6 and controlling the oxygen content in the pulverization gas (nitrogen) when making the fine powder to change the oxygen content in the final sintered body, the other was obtained in the same manner as in Experimental Example 1. 3 types of permanent magnets (samples 6 to 8). Magnetic properties and the like were measured in the same manner as in Experimental Example 1 for the obtained three types of permanent magnets. The results are shown in Fig. 7 . In addition, Ts in FIG. 7 means a sintering temperature, and other symbols are the same as those in FIG. 2 .

[0134] As shown in Fig. 7, it can be seen that all the permanent magnets of samples 6 to 8 have a residual magnetic flux density of 1.4T or more, a coercive force of around 1000kA / m, and a coercive force of 400kJ / m 3 near the higher maximum energy product.

[0135] Next, the magnetic susceptibility (Pc=2) of the permanent magnets of samples 6 t...

experiment example 3

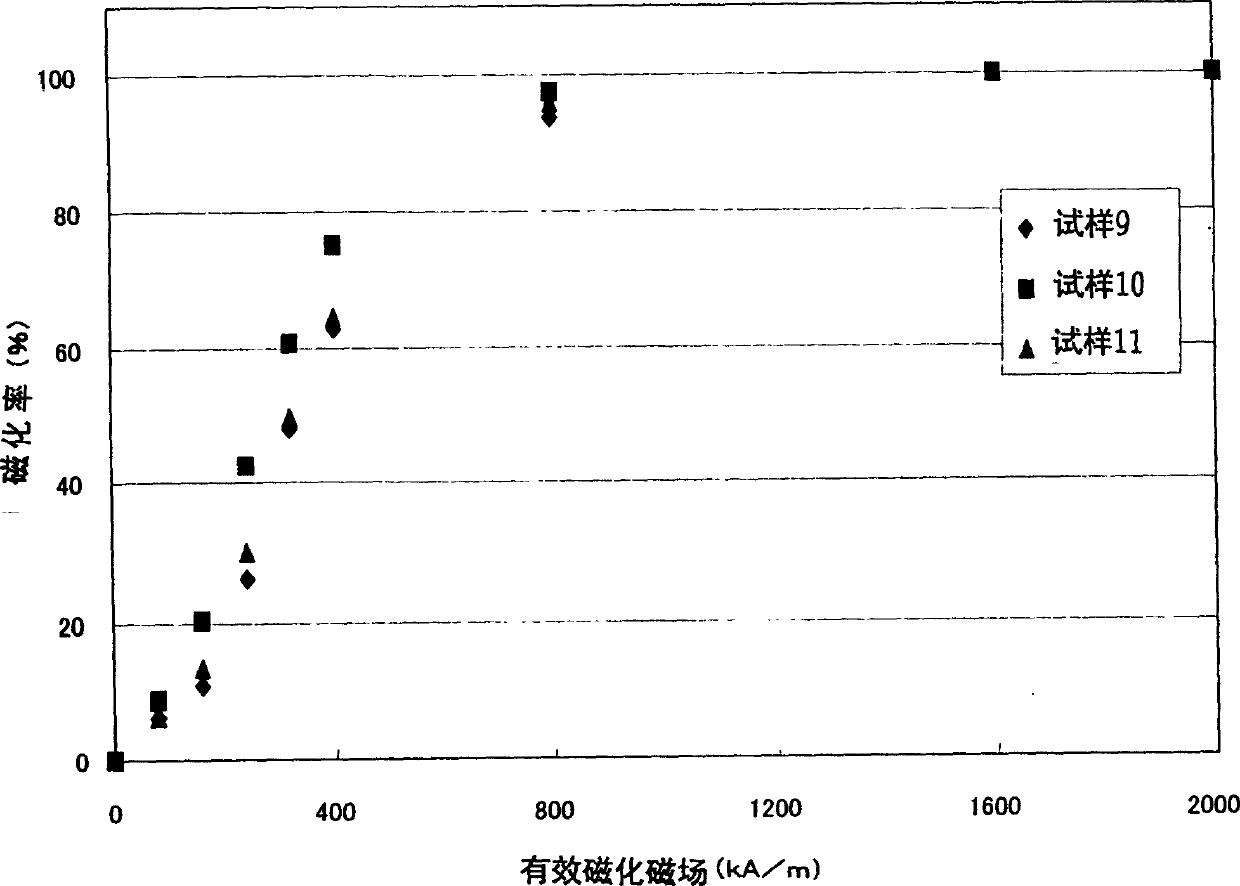

[0138] Three types of permanent magnets (samples 9 to 11) were obtained in the same manner as in Experimental Example 1 except that the raw material alloys shown in FIG. 10 were used. Magnetic properties and the like were measured in the same manner as in Experimental Example 1 for the obtained permanent magnets. The results are shown in Fig. 11 . In addition, the symbols in FIG. 11 are the same as those in FIG. 7 .

[0139] As shown in Fig. 11, it can be seen that sample 9 which does not contain M element has a very low square ratio of 60.22%, and is not a practical permanent magnet; sample 10 containing Zr as M element and sample 11 containing Ti, All have a residual magnetic flux density above 1.4T, a coercive force near 1100kA / m, and a coercive force of 400kJ / m 3 Around this higher maximum energy product.

[0140] The microstructure of Sample 9 was observed, and in Sample 9, abnormally grown crystal grains up to about 100 μm were observed in the sintered body. This is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com