Manufacture of forging decorative door or window frame with straight bars

A manufacturing method and straight rod technology, which can be applied to household components, household utensils, and other household utensils, etc., which can solve problems such as complicated manufacturing process, difficulty in completely covering, and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

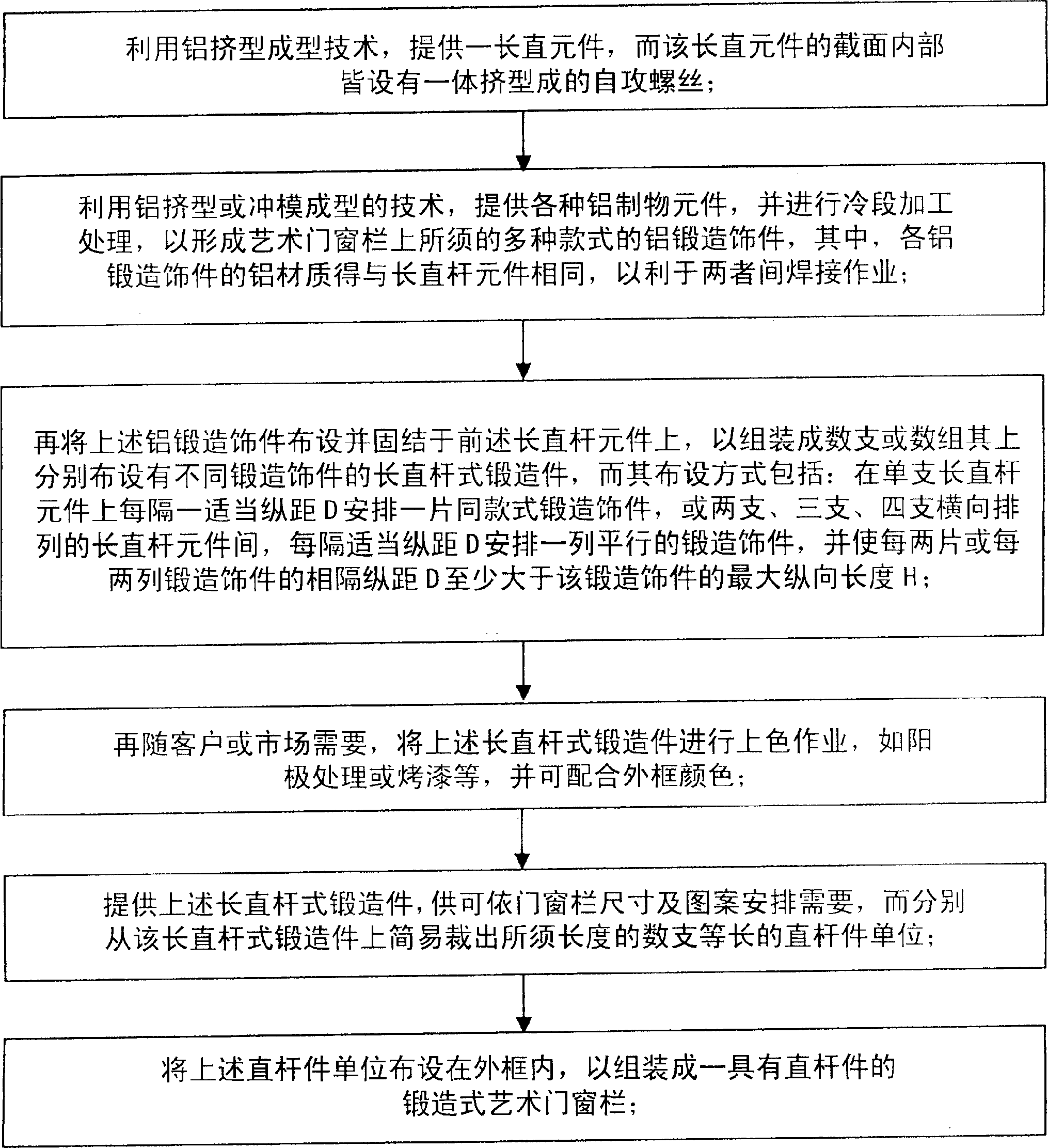

[0046] like figure 1 Shown, the present invention has the manufacture method of the forged type artistic door and window column of straight bar, comprises the following steps:

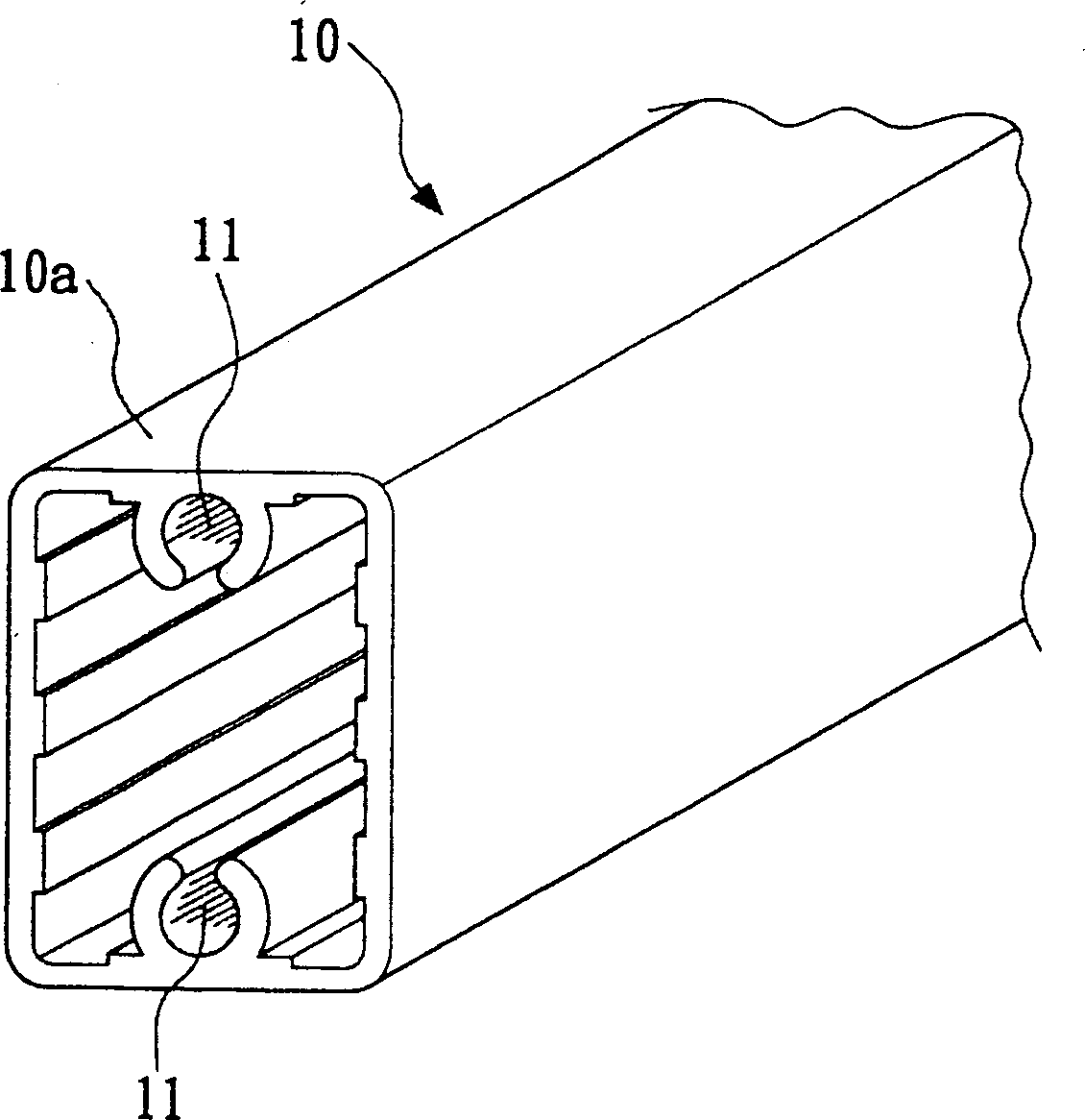

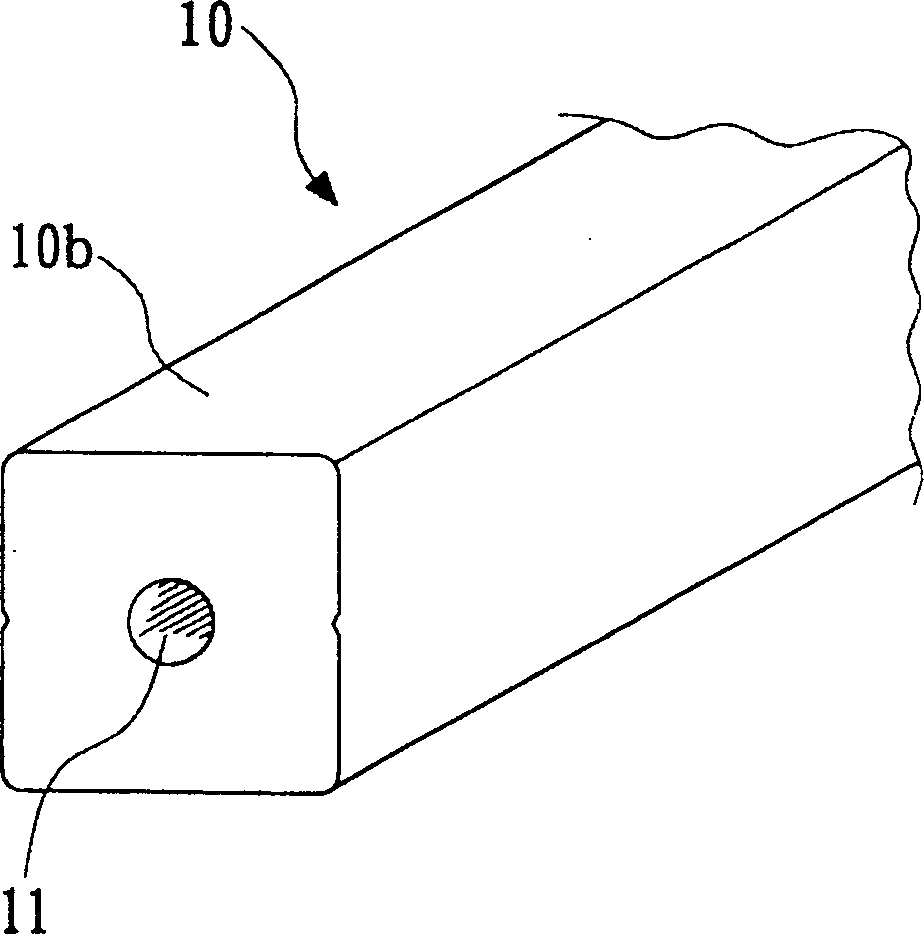

[0047] (1), utilize aluminum extruded molding technology, provide a long straight bar assembly 10, as figure 2 , Figure 2A As shown, its length is preferably 6m to meet the maximum specifications of the coloring equipment. For example, the maximum length and depth of the electroplating tank in a general aluminum electroplating field is 6m; The self-tapping screw seat 11 can be directly locked and combined with the outer frame; and the extruded section of the long straight rod component 10 can be shaped as a hollow frame material such as figure 2 The long straight rod assembly 10a shown, or the solid rod shape such as Figure 2A The long straight rod assembly 10b is shown, and if the long straight rod assembly 10b is used, the optional section of the rod body is rotated to produce a helical patter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com