Weld metals with superior low temperature toughness jfor joining high strength, low alloy steels

A technology of weld metal and alloy elements, which is applied in the field of weld metal, can solve problems such as suboptimal pipelines, achieve good hydrogen-induced cracking resistance, high strength, and avoid hydrogen-induced cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

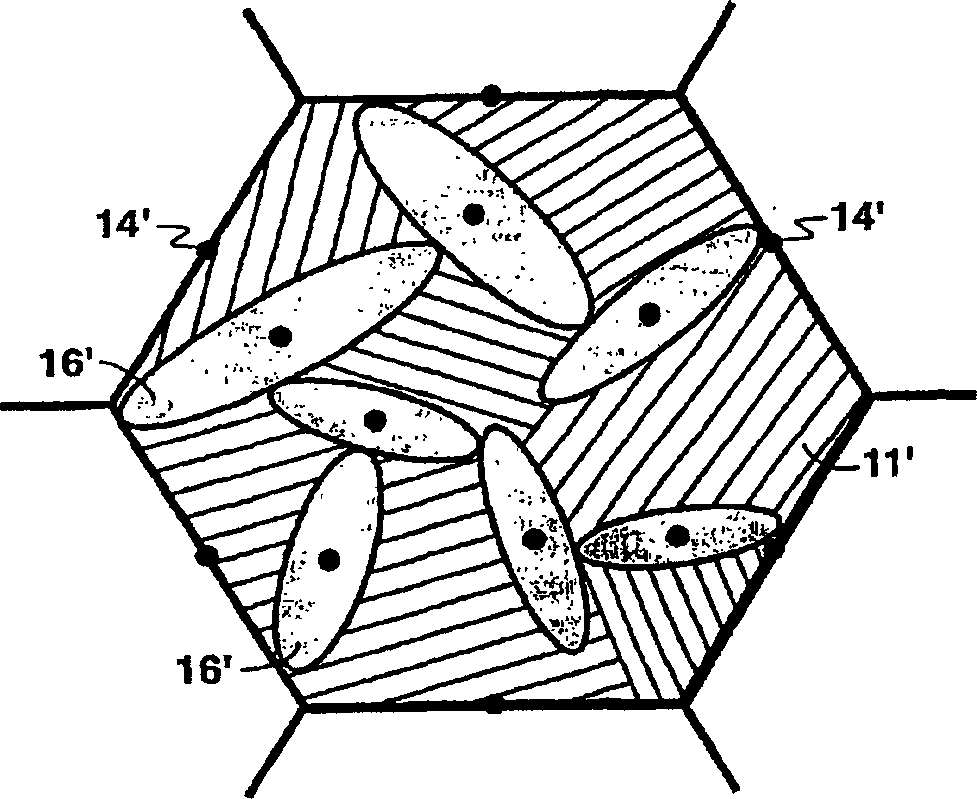

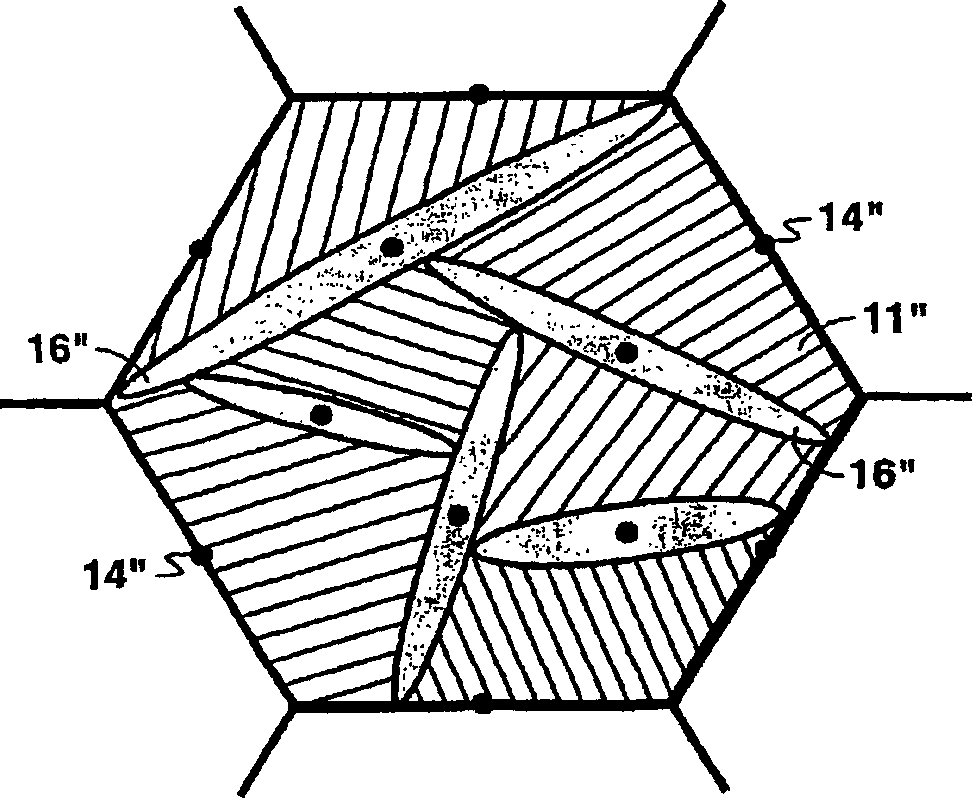

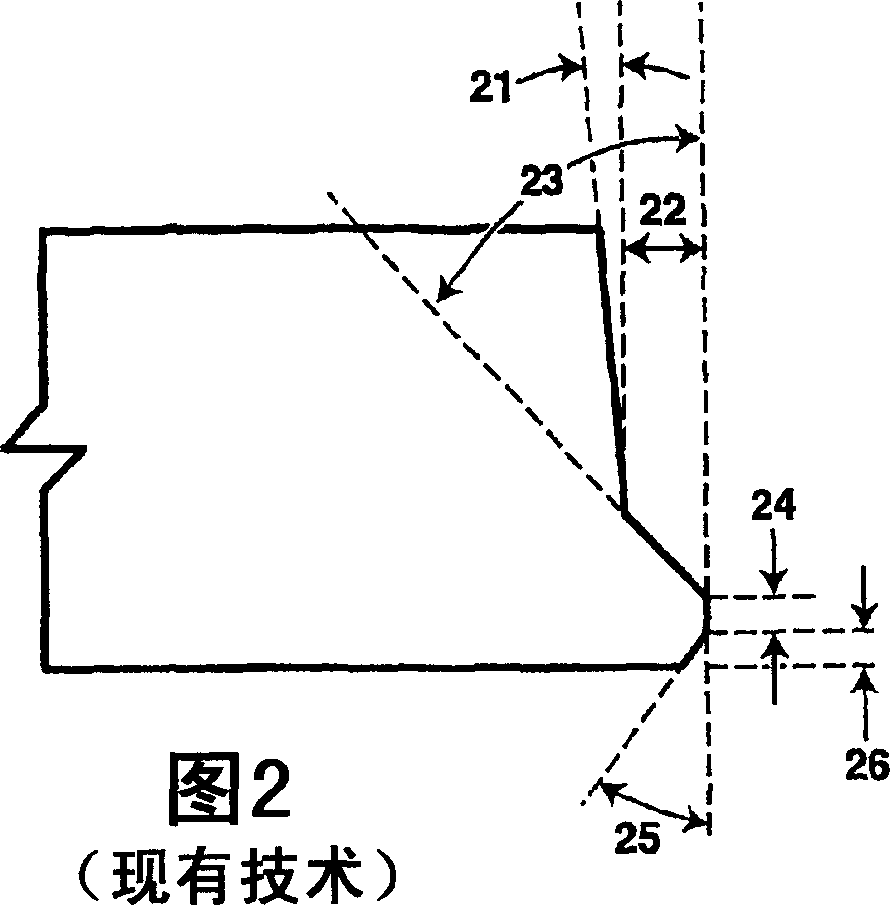

[0046] A weld metal is provided comprising: iron, about 0.04-0.08 wt% carbon, about 1.0-2.0 wt% manganese, about 0.2-0.7 wt% silicon, about 0.30-0.80 wt% molybdenum, about 2.3 - 3.5 wt% nickel, about 0.0175-0.0400 wt% oxygen, and at least one of the following additional elements: up to about 0.04 wt% zirconium and up to about 0.02 wt% titanium. The weld metal according to the present invention may also contain less than about 0.01 wt % phosphorus, less than about 0.01 wt % sulfur, up to about 0.03 wt % aluminum and less than about 0.020 wt % nitrogen. Additionally, the weld metal may contain at least one of up to about 0.60 wt% chromium, up to about 0.60 wt% copper, up to about 0.040 wt% vanadium, and up to about 0.0012 wt% boron. Given the chemical composition of the desired weld metal and the chemical composition of the steel to be welded, one skilled in the art can use known methods to determine the necessary composition of the molten welding wire. The microstructure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com