Method for extracting glycerrhizic acid from licorice

A technology of glycyrrhizic acid and licorice, applied in the directions of steroids, organic chemistry, etc., can solve the problems of high energy consumption of glycyrrhizic acid hydrolysis and oxidative denaturation, long time consumption, and high cost, and achieve simplified operation, high extraction efficiency, and recovery rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

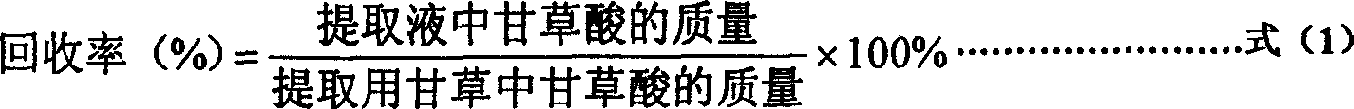

[0022] Embodiment 1. extract glycyrrhizic acid from Radix Glycyrrhizae

[0023] After the fresh licorice with a diameter of 0.5-1.5 cm was air-dried, it was processed into licorice samples of different particle sizes. Weigh 5 grams of licorice sample and place in a flask, add 100ml of water to mix, put into microwave-assisted extraction equipment, microwave heating power is 700W, carry out microwave interval heating for 4 minutes, filter while hot, and obtain glycyrrhizic acid extract. After cooling, fix the solution, adopt HPLC method to analyze the content of glycyrrhizic acid in the extract, and calculate the recovery rate of glycyrrhizic acid according to formula (1) to be 80.3%.

[0024]

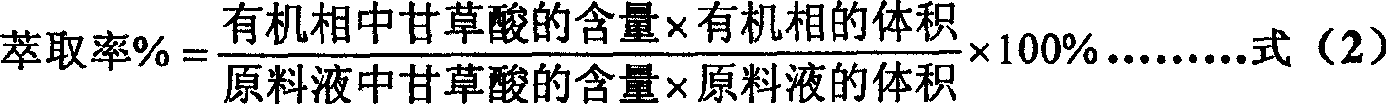

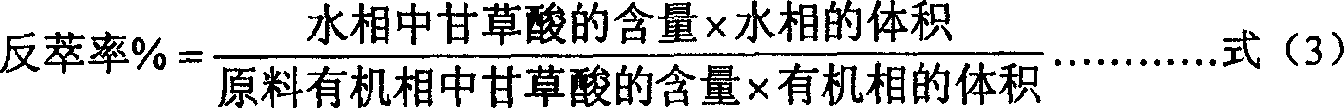

[0025] 100ml of the glycyrrhizic acid extract and 20ml of petroleum ether containing 10% TRPO were added respectively to a beaker and magnetically stirred. Add sulfuric acid while stirring to adjust the pH value of the mixture to 3.0, then transfer the mixture to a centrifuge tube, ...

Embodiment 2

[0032] Embodiment 2. extract glycyrrhizic acid from Radix Glycyrrhizae

[0033] After the fresh licorice with a diameter of 0.5-1.5 cm was air-dried, it was processed into licorice samples of different particle sizes. Weigh 5 grams of licorice sample and place in a flask, add 100ml of water to mix, put into microwave-assisted extraction equipment, microwave heating power is 500W, carry out microwave interval heating for 6 minutes, filter while hot, and obtain glycyrrhizic acid extract. After cooling, the solution was fixed, and the HPLC method was used to analyze the content of glycyrrhizic acid in the extract, and the recovery rate of glycyrrhizic acid calculated by formula (1) was 70%.

[0034] 100ml of this glycyrrhizic acid extract and 100ml of TBP petroleum ether containing 50% were added into a beaker respectively, and magnetically stirred. While stirring, add hydrochloric acid to adjust the pH value of the mixture to 3.0, then transfer the mixture to a centrifuge tube,...

Embodiment 3

[0038] Embodiment 3. extract glycyrrhizic acid from Radix Glycyrrhizae

[0039] After the fresh licorice with a diameter of 0.5-1.5 cm was air-dried, it was processed into licorice samples of different particle sizes. Weigh 5 grams of licorice sample and place it in a flask, add 100ml of water to mix, put into microwave-assisted extraction equipment, microwave heating power is 200W, carry out microwave interval heating for 10 minutes, filter while hot, and obtain glycyrrhizic acid extract. After cooling, the solution was fixed, and the HPLC method was used to analyze the content of glycyrrhizic acid in the extract, and the recovery rate of glycyrrhizic acid calculated by formula (1) was 65%.

[0040] 100ml of the glycyrrhizic acid extract and 50ml of n-hexanol were added to the beaker respectively, and magnetically stirred. While stirring, add hydrochloric acid to adjust the pH value of the mixture to 2.5, then transfer the mixture to a centrifuge tube, centrifuge for 3 min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com