Coagulate method of water treatment purifying technology

A purification process and water treatment technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor relative molecular weight and particle size flocculation bridging ability, unsatisfactory effect, and insufficient stability of water purification effect, etc., to achieve The effect of water purification is remarkable, the treatment effect is stable, and the effect of short storage time is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

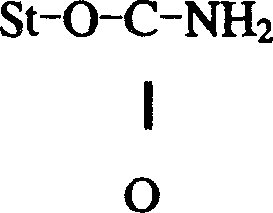

Image

Examples

Embodiment approach 1

[0016] The first embodiment of the method of the present invention is: an inorganic polymer metal salt flocculant—a coagulation method combining polyferric phosphate sulfate and urea starch.

[0017] The preparation method of polymeric ferric phosphate sulfate in this embodiment is as follows: (1) At room temperature, the mixture of ferrous sulfate and concentrated sulfuric acid is mixed and reacted with an aqueous solution of chlorine dioxide for more than 30 minutes; wherein the concentration of the aqueous solution of chlorine dioxide is 1.8 -2.2%, ferrous sulfate is FeSO 4 ·NH 2 The value range of O, n is between 0-8, and the concentration of concentrated sulfuric acid is above 98%; the mass ratio of ferrous sulfate, concentrated sulfuric acid, and chlorine dioxide aqueous solution is (5.8-6.1):1:( 3.8-4.0); (2) Add inorganic phosphate to the product obtained in (1) for polymerization, PO 4 3- / Fe mole ratio is 0.08-0.11; (3) to prepare polyferric phosphate sulfate (liquid). ...

Embodiment approach 2

[0021] The method embodiment of the present invention 2: Use inorganic polymer metal salt flocculant-polyaluminum chloride ([Al 2 (OH) n (SO 4 ) (3-n) / 2 ] m , N3) and urea starch are mixed in the form of an aqueous solution, and then directly added to the raw water to be treated; the mass ratio of polyaluminum chloride and urea starch is 10:1.

Embodiment approach 3

[0022] The method embodiment of the present invention 3: Use inorganic polymer metal salt flocculant——Polyferric sulfate ([Fe 2 (OH) n (SO 4 ) (3-n) / 2 ] m , N3) and urea starch are mixed in the form of an aqueous solution, and then directly added to the raw water pipeline for mixing. The dosage of these two coagulants is controlled by a metering pump. The mass ratio of polyferric sulfate and urea starch is 6:1.

[0023] In the above embodiment of the method of the present invention, the total dosage of metal salt flocculant and urea starch is generally about 1.8 kg / ton of raw water (low turbidity), and 2-2.7 kg / ton of raw water (high turbidity).

[0024] The preparation method 1 of urea starch in the present invention is: after mixing urea, dried corn starch, and aqueous solution, the resulting compound is kept under stirring at a temperature of 90°C for 4 hours and dried, and the quality of the urea, dried corn starch, and aqueous solution They are 1 kg, 20 kg, and 20 kg respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com