Electrode member for plasma treating appts., plasma treating appts. and plasma treating method

A plasma and electrode element technology, applied in the field of plasma treatment, can solve the problems of inability to discharge electrodes, thermal shock damage of discharge electrode plates, etc., and achieve the effects of uniform etching without deviation, uniform injection pressure, and prevention of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Next, an embodiment of the present invention will be described with reference to the drawings.

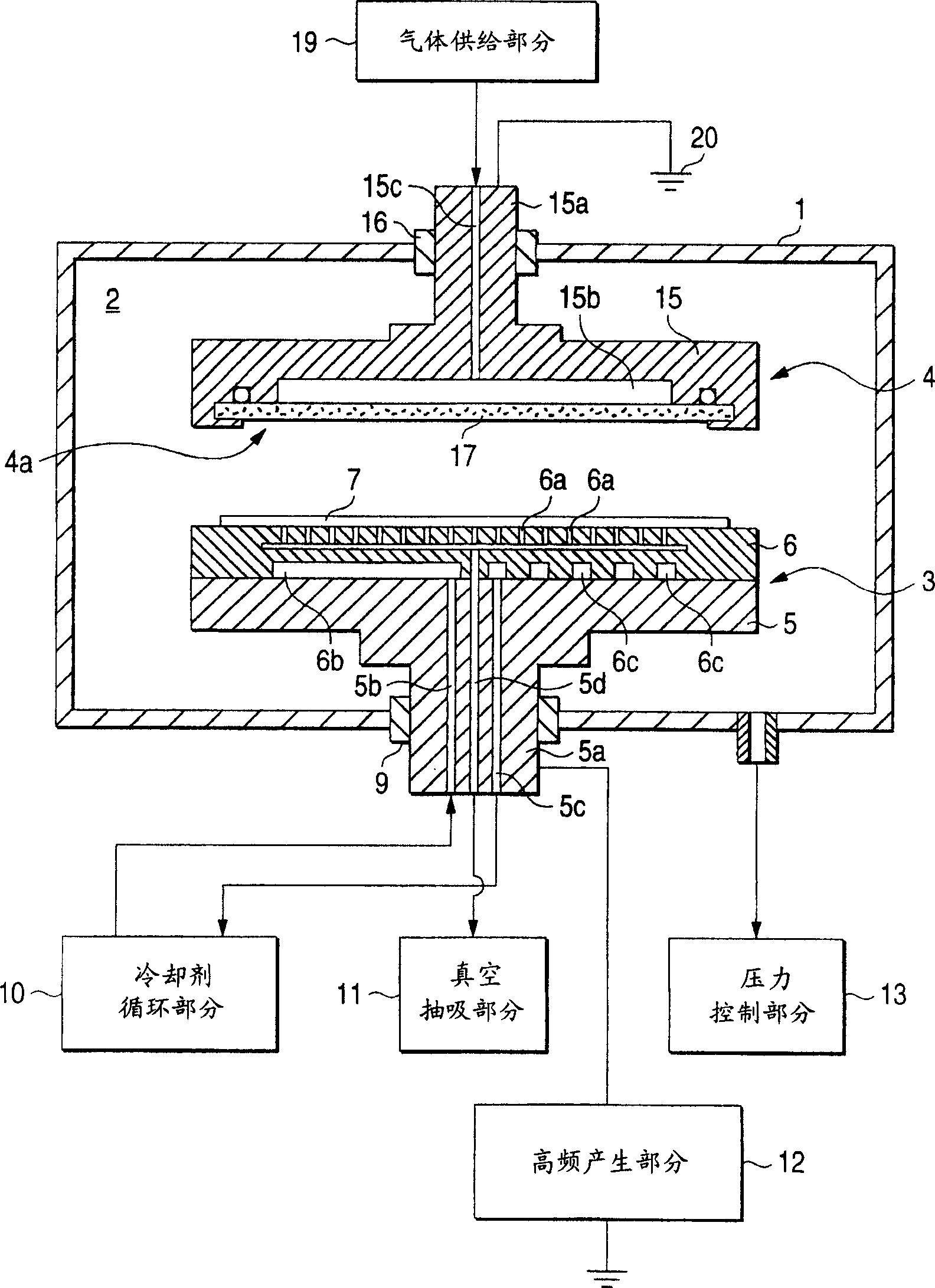

[0052] First, refer to figure 1 The plasma processing apparatus will be described. figure 1Among them, the inner side of the vacuum chamber 1 is a processing chamber 2 for performing plasma processing. The lower electrode 3 (first electrode) and the upper electrode 4 (second electrode) are lined up in the processing chamber 2 for plasma processing. The lower electrode 3 (first electrode) and the upper electrode 4 (second electrode) are vertically opposite to each other in the processing chamber 2 . The lower electrode 3 includes an electrode body 5 which is mounted on the vacuum chamber 1 with a supporting portion 5a through an insulator 9 made of polytetrafluoroethylene to extend downward. A holding part 6 made of high thermal conductivity material such as aluminum, stainless steel or other suitable materials is installed on the upper surface of the electrode body 5, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com