Machine cutting flutter on-line intelligent control system

An intelligent control system and flutter technology, applied in non-rotational vibration suppression, manufacturing tools, metal processing machinery parts, etc., can solve the difficulties in the mathematical model of the cutting processing system, the inability to control cutting stability online, and the inability to eliminate chatter phenomena And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

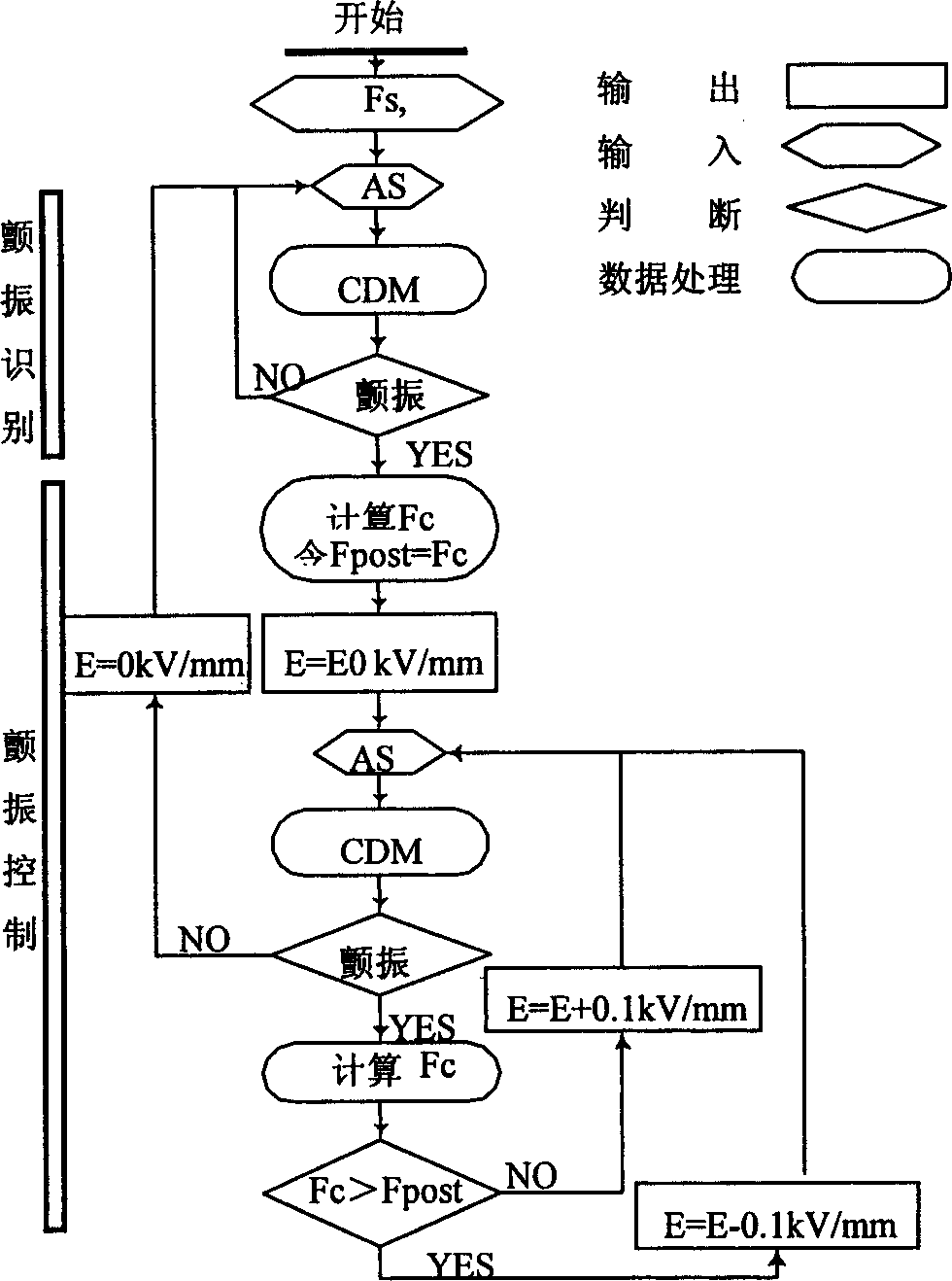

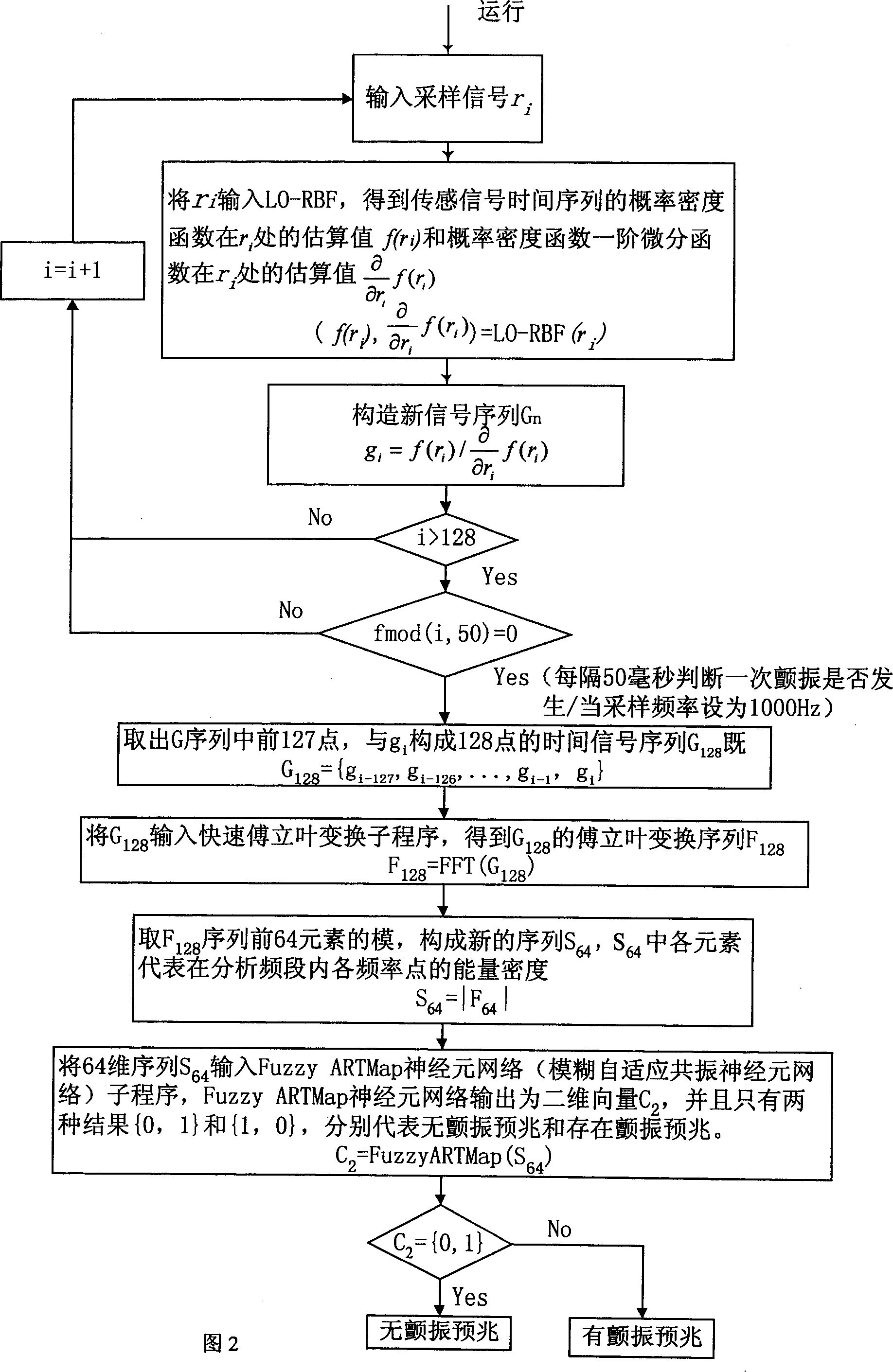

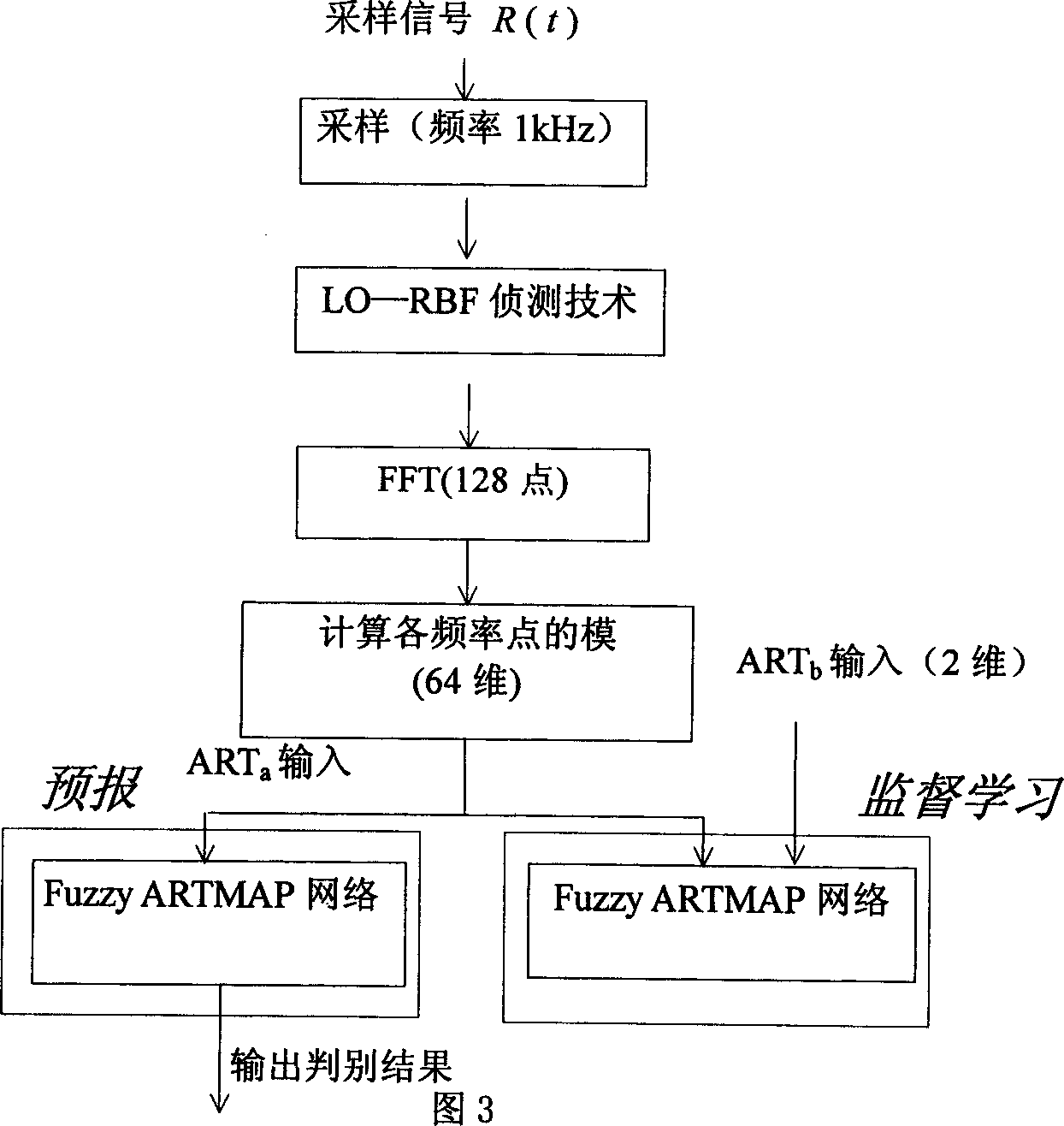

Method used

Image

Examples

Embodiment Construction

[0062] The present invention can be used in boring machining. Because boring is inner hole processing, the boring bar is generally designed as a slender cantilever beam structure, which has poor rigidity and is prone to bending deformation under force, and chatter is often unavoidable when subjected to dynamic cutting forces. In order to overcome the weakness that the rigidity of the boring bar cannot be fundamentally improved, the present invention adds a smart material——electrorheological material to its structural design. By applying an electric field to the electrorheological material, the overall dynamic characteristics of the boring bar can be changed online, combined with flutter The online prediction technology adjusts the dynamic characteristics of the boring bar online according to the sensor signal to avoid the occurrence of chatter.

[0063] In this embodiment, the system is based on Figure 4 Assembled according to conventional technology, the accessories used an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com