Fuel cell having thermo-responsive polymer

A fuel cell and polymer technology, applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve problems such as non-transmission, fuel cell performance degradation, and poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

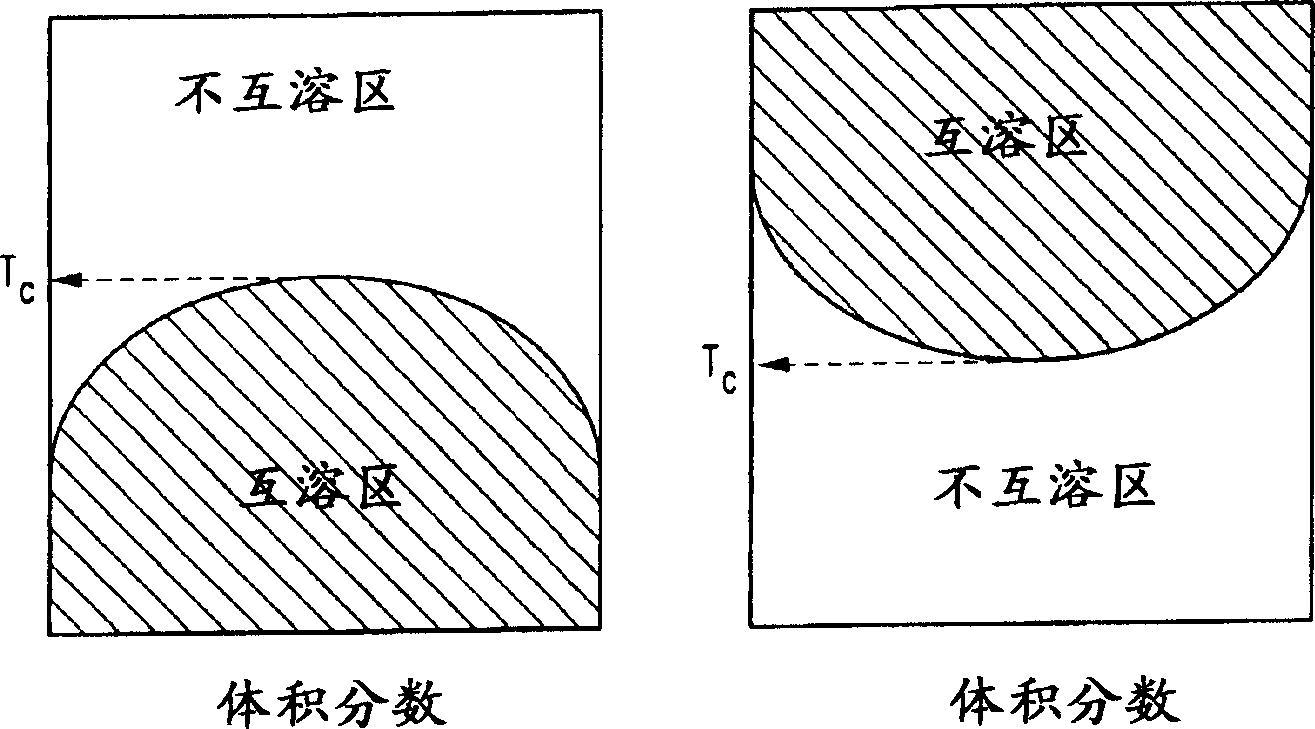

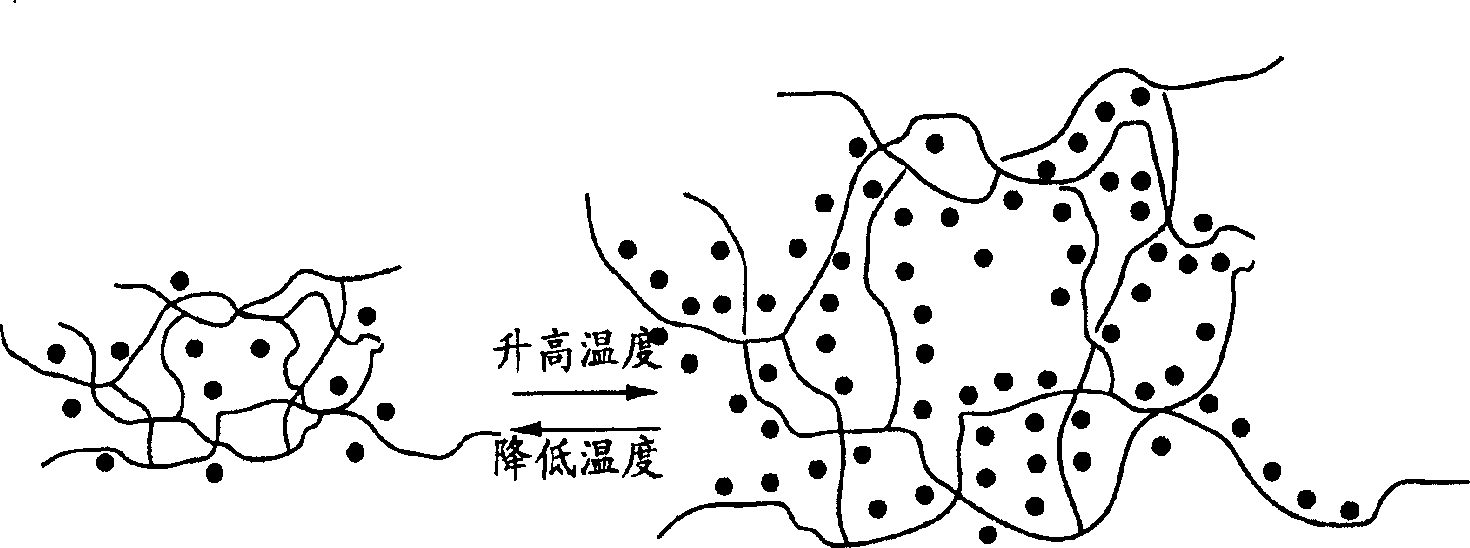

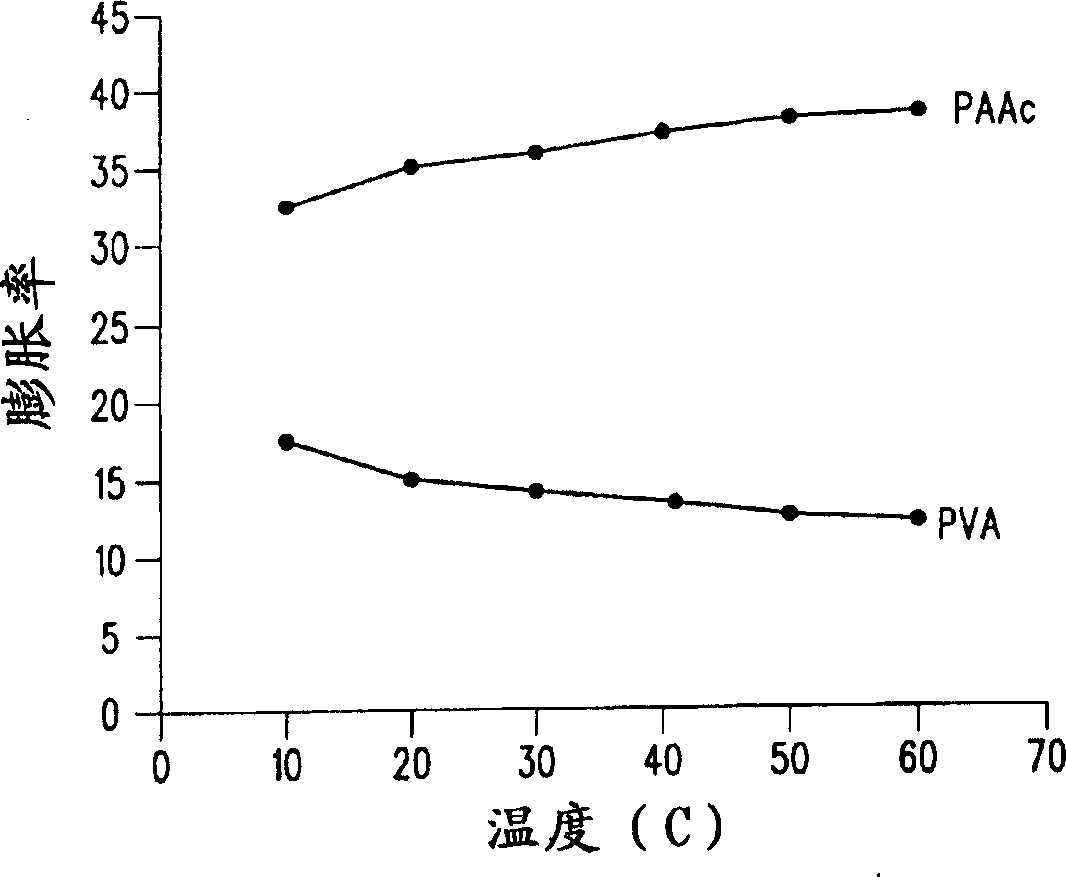

[0014] Although this specification can draw the conclusion that the claims defining the features of the present invention are considered novel, it is believed that the structure, operation method and advantages of the present invention will be better understood by considering the following description in conjunction with the diagrams. Thermal polymers can compensate for hydration by taking advantage of the elevated temperature experienced by the fuel cell during operation and the transition from hydrophobic to hydrophilic (and vice versa) the fuel cell undergoes at elevated temperatures. In order to maintain the optimal hydration of the polymer electrolyte membrane, a thermosensitive polymer is included in the fuel cell. The thermal polymer is close to the membrane electrode assembly, so that the fuel and oxidant gas pass through the thermal polymer to reach the membrane electrode assembly. In response to changes in the operating temperature of the membrane electrode assembly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com