High-resisting silicon carbide substrate for semiconductor devices with high breakdown voltage

A technology of silicon carbide substrate and silicon carbide, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of difficult and ineffective manufacturing and growth processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

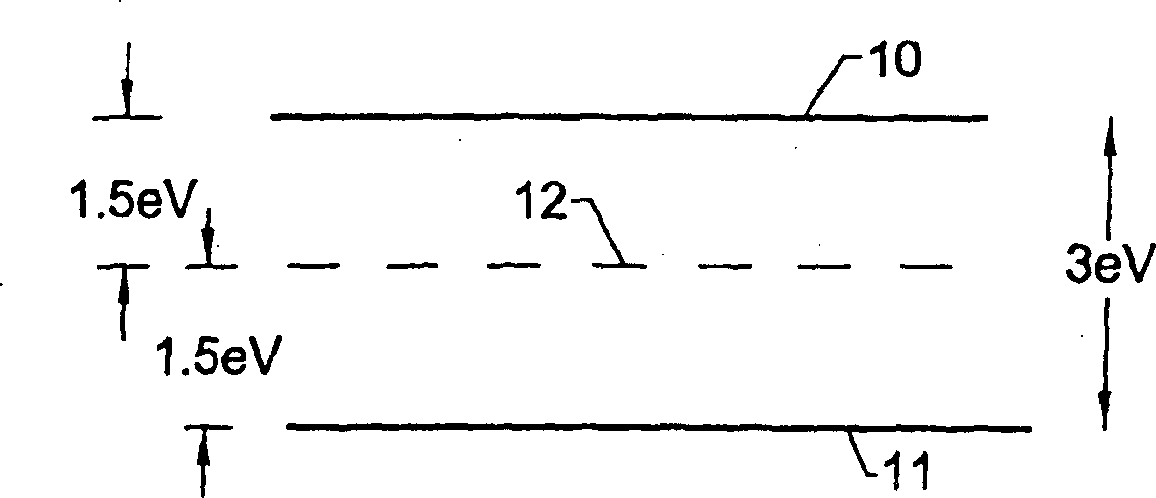

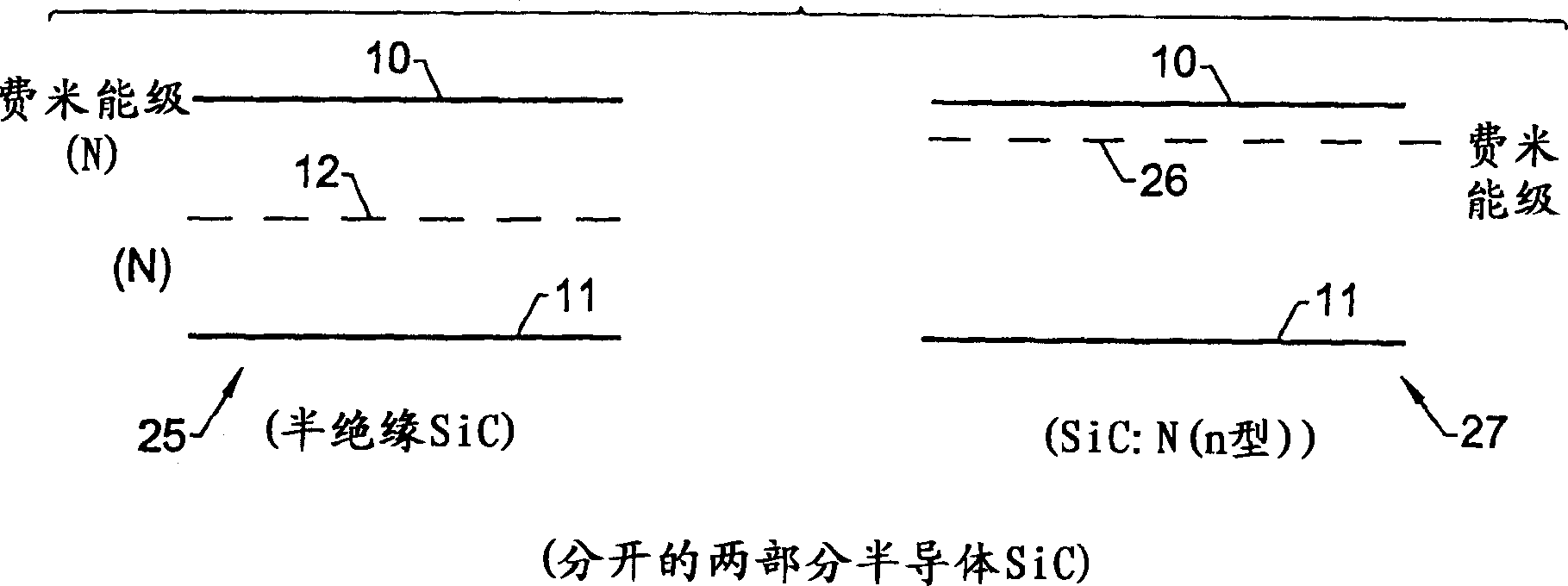

[0030]The present invention is a high-resistance silicon carbide single crystal, the single crystal contains at least one compensating dopant, the electronic energy level of which is far away from the edge of the silicon carbide band gap to avoid conductive behavior, when the substrate is in contact with the doped silicon carbide epitaxial layer , and when the net dopant content in the crystal is sufficient for the Fermi level to be pinned at the electronic level of the dopant, the electronic energy level far enough from the middle of the bandgap towards the band edge will be lower than the intermediate energy state (e.g., traps, defects, elements, etc.) produce a larger energy band difference, so that the resulting silicon carbide single crystal has a resistivity of at least 5,000 Ωcm at room temperature (298K).

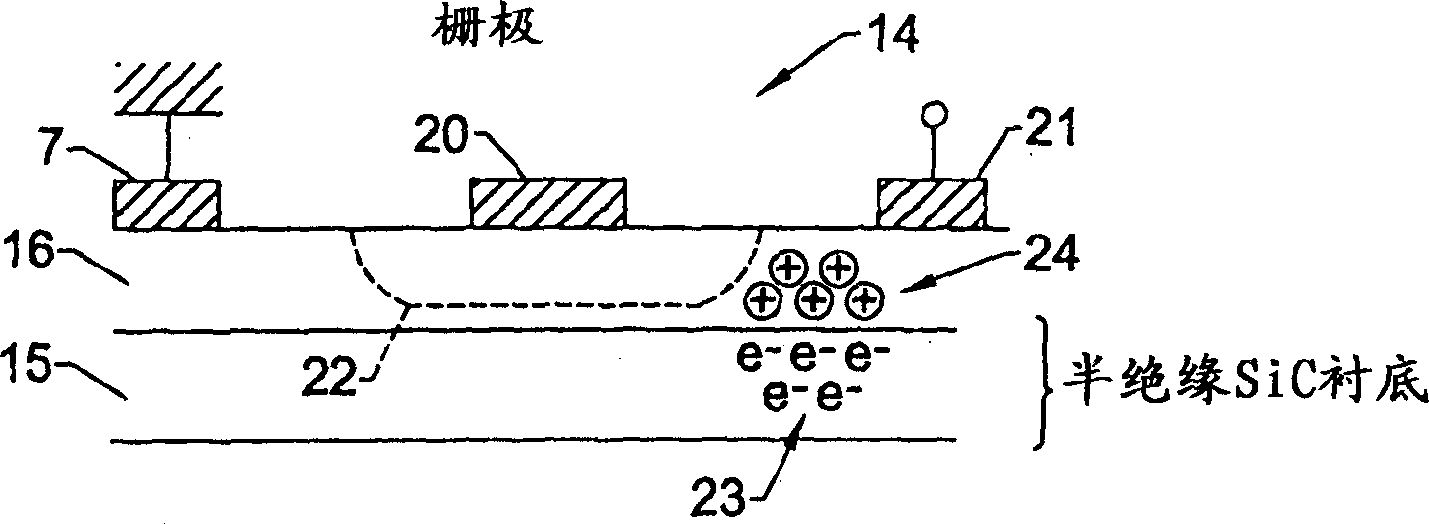

[0031] The present invention is particularly advantageous in a structure in which the epitaxial layer or a functionally equivalent active layer (for example, diffuse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com