Method for high yield alpha, omega-n-long chain tetradecabinary acid by utilizing microbe fermentation

A tetradecane dibasic acid, long-chain technology, applied in the field of ω-normal long-chain tetradecane dibasic acid, simultaneous fermentation of n-tetradecane high-yield α field, can solve the problem that is not suitable for large-scale production of tetradecane dibasic acid Acid biological methods and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] small scale fermentation

[0046] (1) Take an inoculum loop strain (Candida Tropicalis mutagenic strain ES4-6-5, preservation number CCTCC M202042), spread it on the wort slope of the Kjerkner flask, and culture it at 29° C. for two days.

[0047] (2) Take a slant of the above-mentioned strain of Kjeldahl bottle, wash all the bacteria with 100mL of sterile water, insert it into a 10L stirring fermenter equipped with 6L alkane seed medium, and cultivate it at 29°C for 24 hours. The composition of the alkane seed medium is: glucose 15g / L, KH 2 PO 4 8g / L, yeast extract 2g / L, corn steep liquor 1g / L, urea 1.5g / L, NaCl 0.5g / L, C 14 Normal alkanes 40mL / L, prepared with tap water, pH natural.

[0048] (3) In a 10L fermenter equipped with 6L medium, 1.0L of the above-mentioned seed solution was inserted to start fermentation. The composition of the fermentation medium is: glucose 10g / L, KH 2 PO 4 8g / L, yeast extract 1g / L, corn steep liquor 1.5g / L, urea 1g / L, NaCl 1g / L, KNO...

Embodiment 2

[0049] Embodiment 2 large-scale fermentation

[0050] According to the process control of embodiment 1, carry out 5M 3 Tank pilot production. The primary seed tank is 200L, inoculate two Kelvin flasks, the cultivation time is 24-32 hours, the secondary seed tank is 1M 3 , cultivated for 18-24 hours. After 148 hours of fermentation, a total of 905.83kg of alkanes were added, and the volume of the tank was 4.224M 3 ,

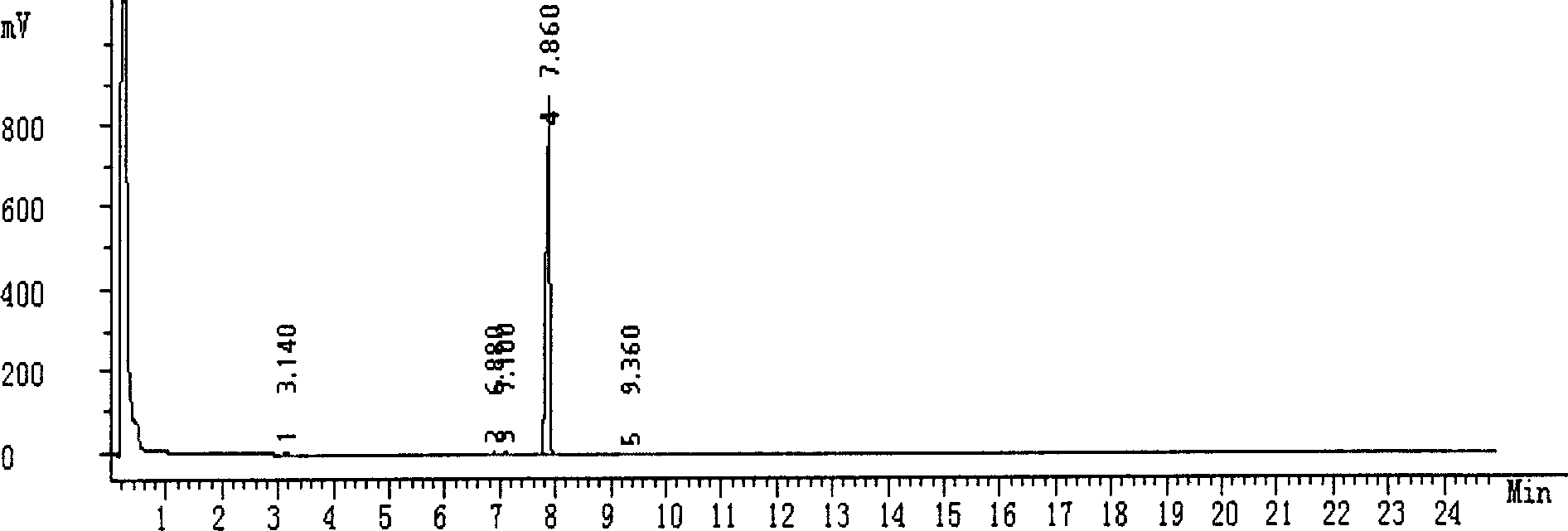

[0051] The content of DC14 in the fermentation stock liquid was determined by gas chromatography to be 197.4g / L, the weight yield of fermentation was 92.18%, and the molar yield was 70.74%. Back extraction obtains 779kg product altogether, and yield is 93.3%, and product is 98.9% through gas chromatography analysis total acid purity, and monoacid content is 98.5% ( figure 1 ).

Embodiment 3

[0053] Small-scale production without adding sugar during fermentation

[0054] Fill 6.0L of liquid in a 10L fermenter to carry out tetradecane dibasic acid fermentation, the composition of the fermentation medium is: sucrose 20g / L, KH 2 PO 4 8g / L, yeast extract 1g / L, corn steep liquor 1.5g / L, urea 1g / L, NaCl 1g / L, KNO 3 7g / L, 20% C14 alkanes, prepared with tap water, natural pH, sterilized at 121°C for 20 minutes. After 24, 48, 72, and 96 hours of fermentation, 300 mL of alkane was added in four batches, and no sugar was added during the process. The rest of the process conditions and controls were the same as in Example 1. After 160 hours of fermentation, the volume of the tank was 7.0 L, and a total of 2400 mL of alkane was added.

[0055] The acid production of the fermentation stock solution was extracted with ether and the NaOH titration method measured the concentration to be 177g / L, the residual hydrocarbon was 2.7%, and the fermentation weight yield was 85%. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com