Method for forming nano TiO2 light catalystic active agenbt coating on substrate

A technology of nano-titanium dioxide and activator, which is applied in metal material coating process, coating, device for coating liquid on the surface, etc., can solve the problems of difficult separation and recovery of photocatalysts, difficult to reuse, etc., and the method is simple and convenient. , The effect of the material coating is firm and the application prospect is broad.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

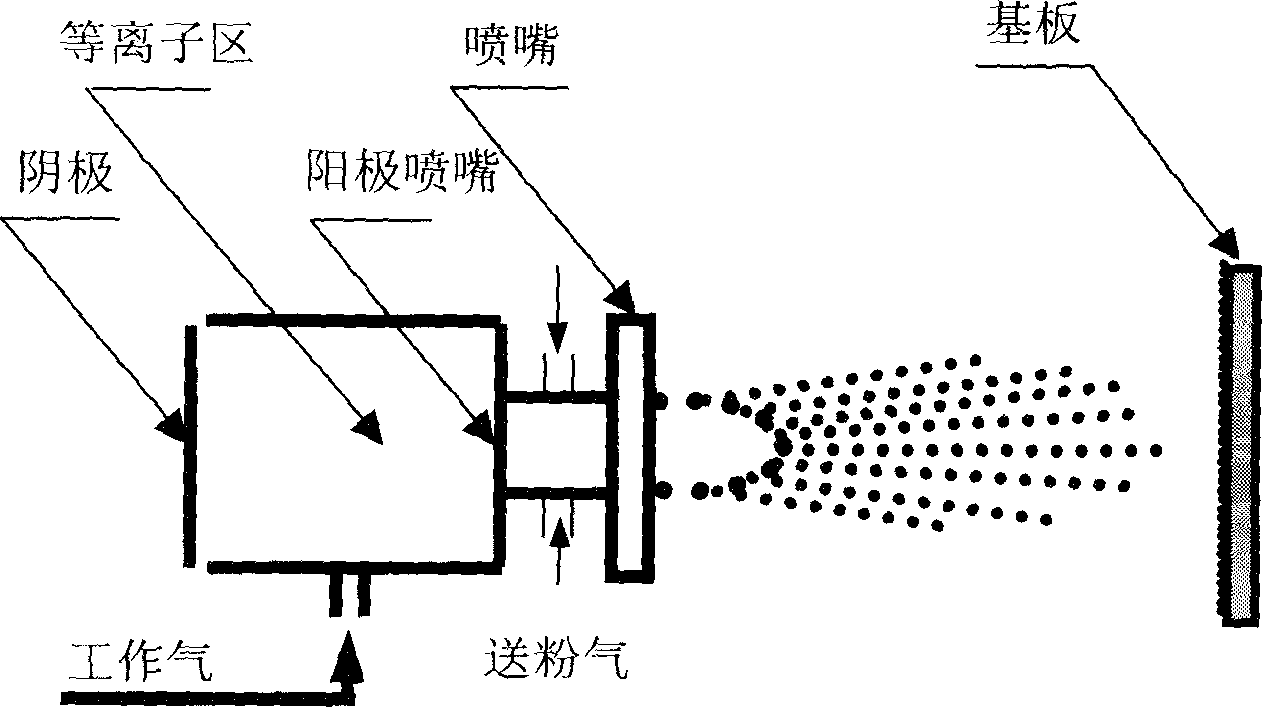

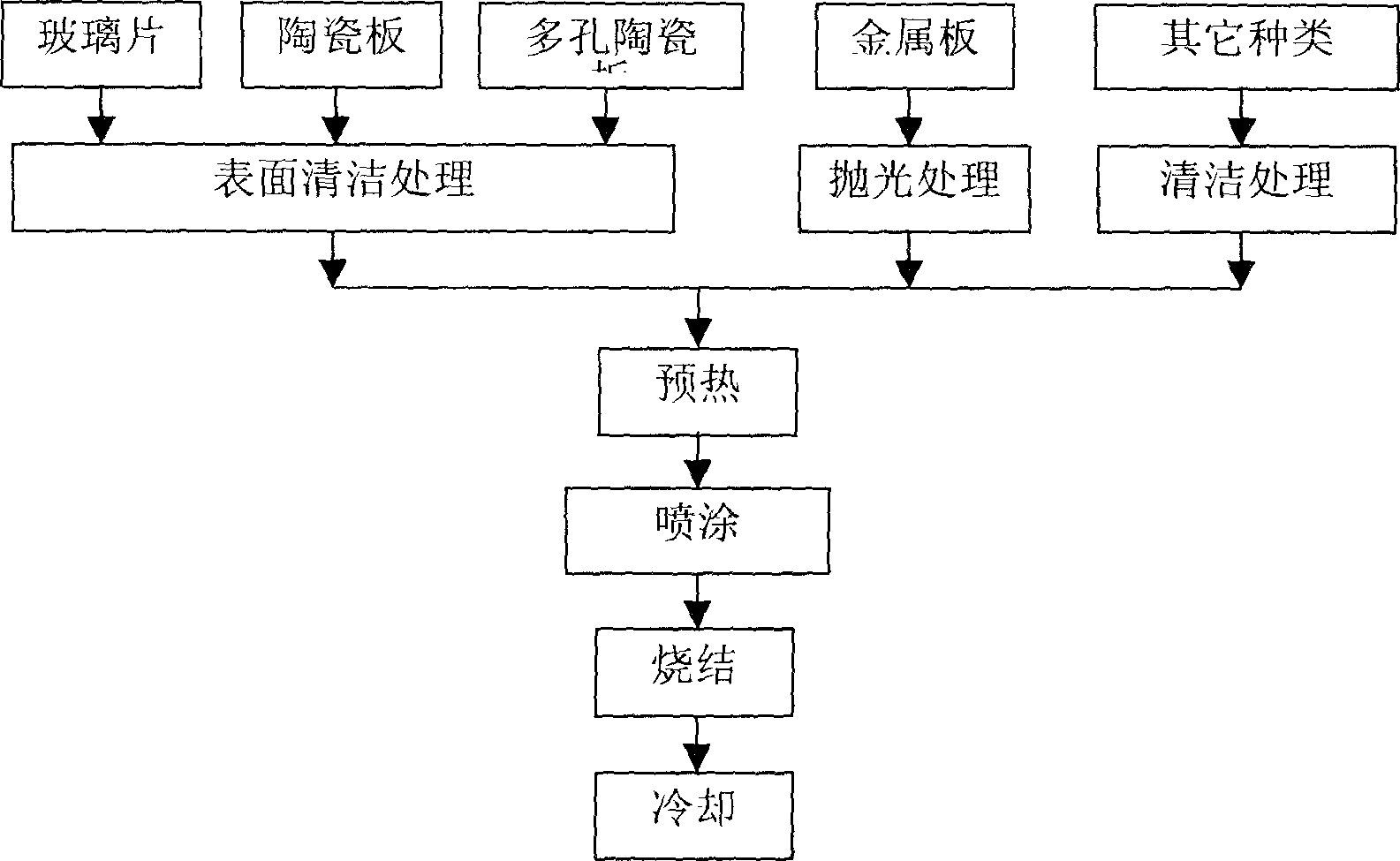

Method used

Image

Examples

Embodiment 1

[0029] Polish the metal aluminum plate first, then heat it to 500°C, keep the temperature for 3 hours, and use plasma spraying equipment to spray anatase phase nano-titanium dioxide powder on the polished side. Nitrogen used for spraying (N 2 ) and ordinary hydrogen (H 2 ) mixed gas, hydrogen accounts for 10% by volume of the mixed gas. The total gas flow of working gas is about 40m 3 / h, the pressure is 0.5MPa, with ordinary nitrogen (N 2 ) is powder gas. Its parameters are: spray distance 200mm, powder feeding flow rate 60g / min, power 27.5kW, control coating thickness at about 1.0μm. After spraying, keep the aluminum plate at a constant temperature of 300°C for 2 hours, and cool it down to room temperature naturally. Under the operating frequency of 20 Hz, the sprayed substrate is ultrasonically treated for 120 min, and the powder shedding rate is ≤5wt%.

Embodiment 2

[0031] Clean the glass sheet first, then heat it to 200°C, and after constant temperature for 2 hours, use plasma spraying equipment to spray anatase phase nano-titanium dioxide powder on its clean surface. Nitrogen used for spraying (N 2 ) and ordinary hydrogen (H 2 ) mixed gas, the proportion of hydrogen in the mixed gas volume is 15%. The total gas flow of working gas is about 40m 3 / h, the pressure is 0.7MPa, with ordinary nitrogen (N 2 ) is powder gas. Its parameters are: spray distance 150mm, powder feeding flow rate 50g / min, power 25.0kW, control coating thickness at about 0.8μm. After spraying, the glass sheet was kept at a temperature of 300°C for 3 hours, and then naturally cooled to room temperature. Under the operating frequency of 20 Hz, the sprayed substrate is ultrasonically treated for 120 min, and the powder shedding rate is ≤5wt%.

Embodiment 3

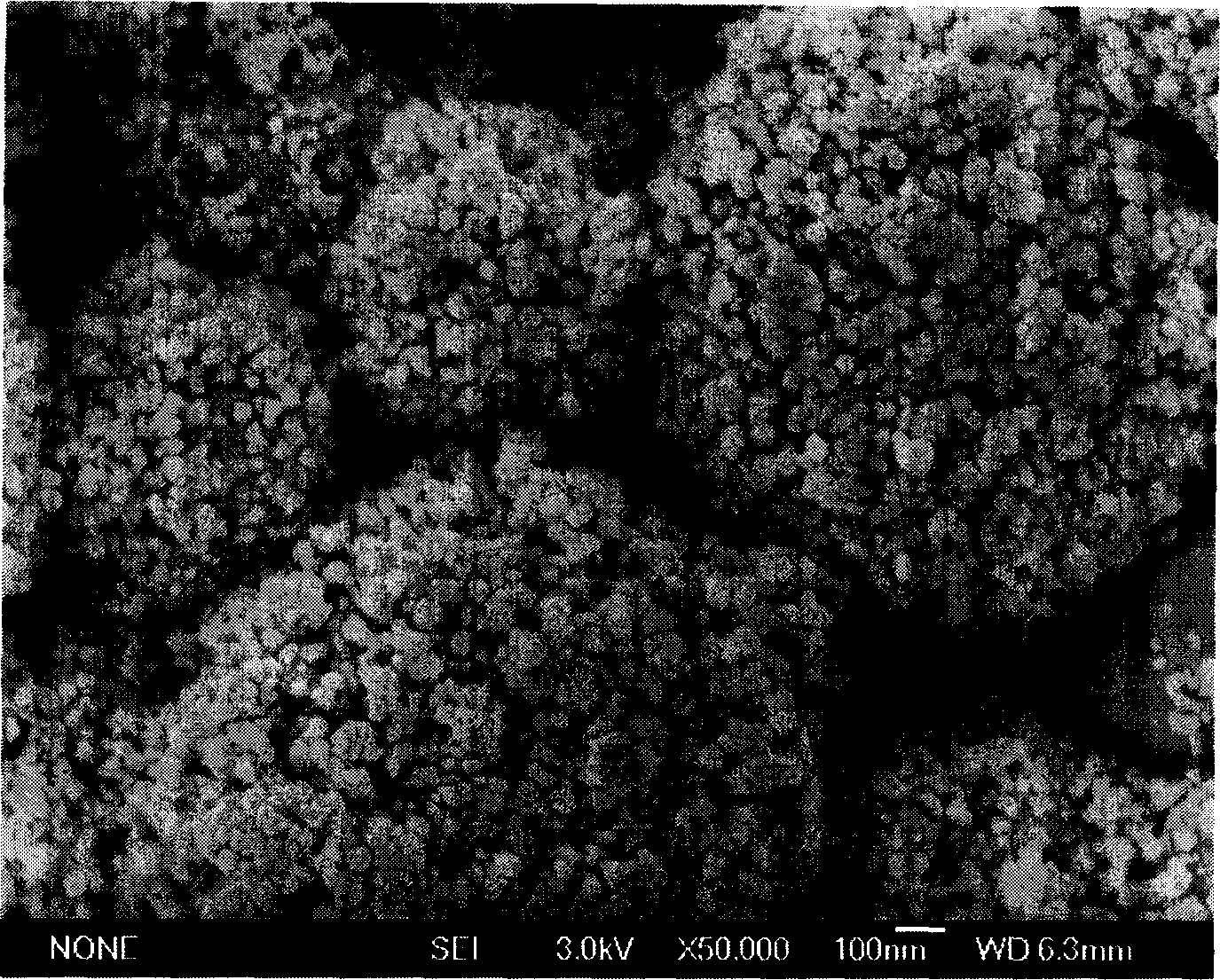

[0033] Clean the ceramic plate first, then heat it to 400°C, and after keeping the temperature constant for 2 hours, use plasma spraying equipment to spray rutile phase nano-titanium dioxide powder on the clean surface. Nitrogen used for spraying (N 2 ) and ordinary hydrogen (H 2 ) mixed gas, the proportion of hydrogen in the mixed gas volume is 20%. The total gas flow of working gas is about 40m 3 / h, the pressure is 0.6MPa, with ordinary nitrogen (N 2 ) is powder gas. Its parameters are: spray distance 200mm, powder feeding flow rate 30g / min, power 40.5kW, control coating thickness at about 1.0μm. After spraying, the ceramic plate was kept at a temperature of 400° C. for 2 hours, and then naturally cooled to room temperature. Under the operating frequency of 20 Hz, the sprayed substrate is ultrasonically treated for 120 min, and the powder shedding rate is ≤5wt%. Its scanning electron microscope image is attached image 3 For comparison with its photocatalytic activit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com