Miniature turbine jet engines

A technology of jet engine and microturbine, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problem of no microturbine engine, etc., and achieve the effect of increasing the thrust-to-weight ratio and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

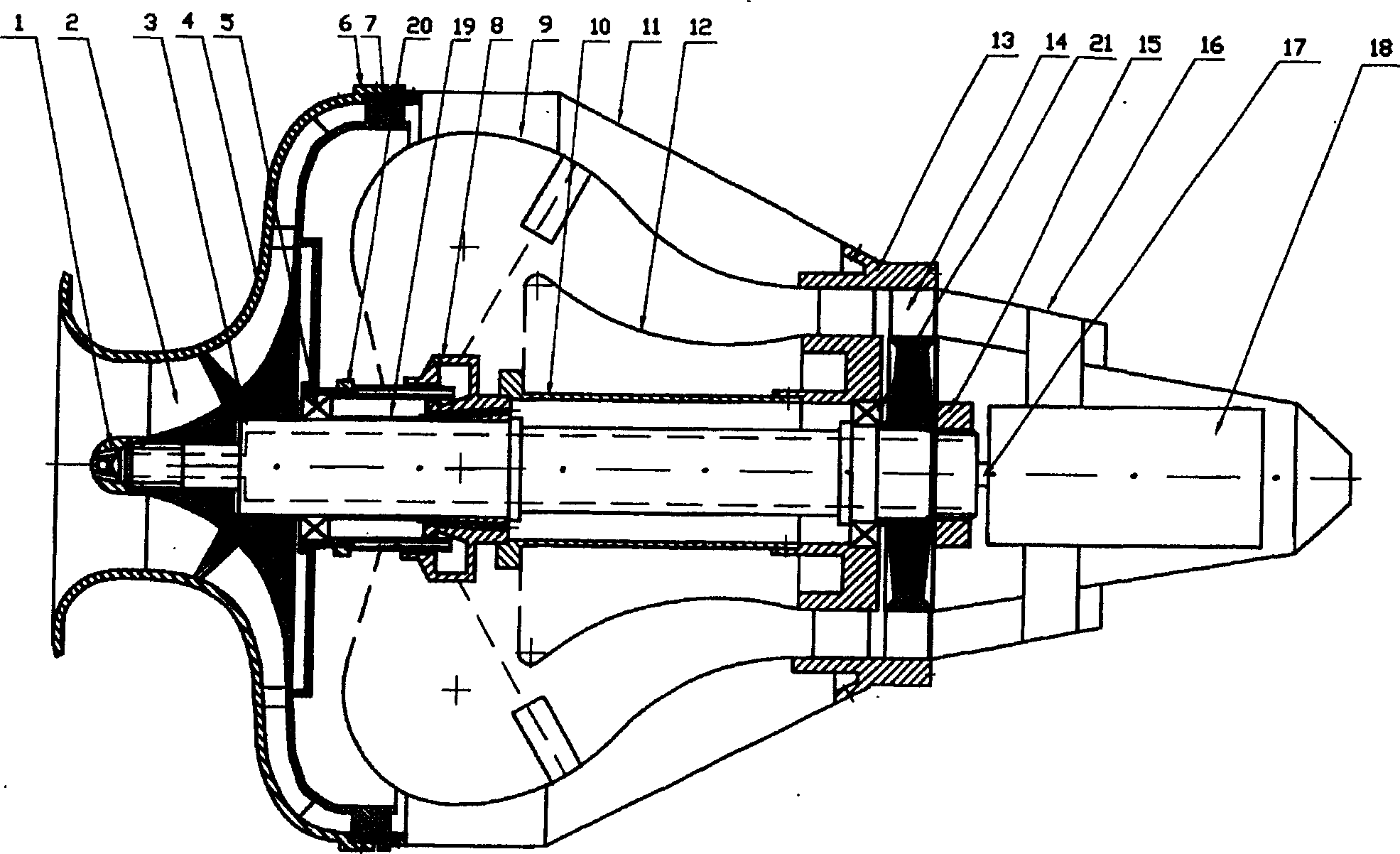

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

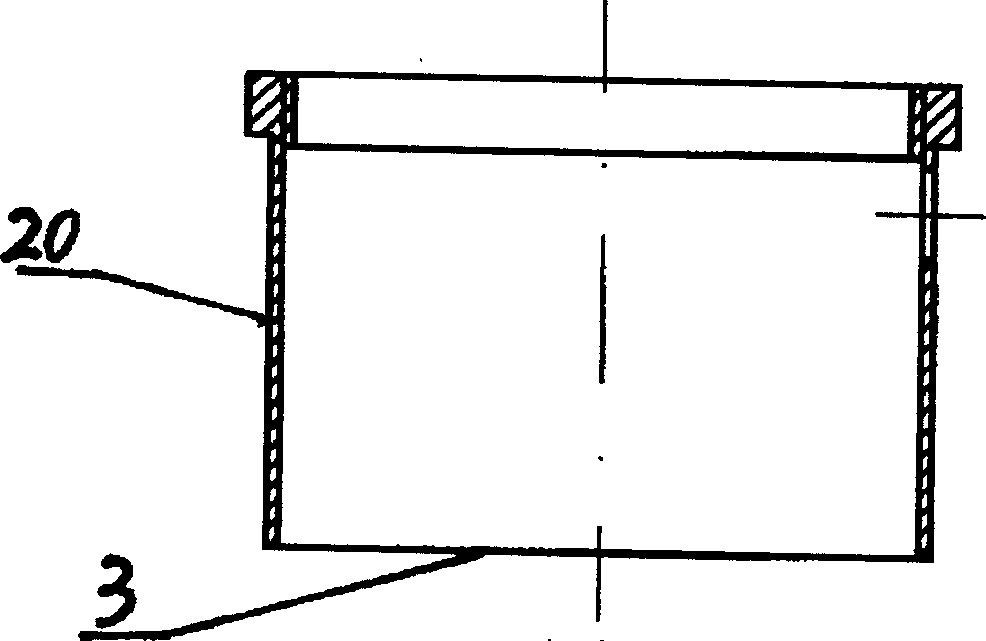

[0024] Please refer to the accompanying drawings, in the figure, the front nut 1 is mounted on the front end of the shaft 3, and is used to compress the centrifugal compressor rotor 2, the front bearing 5, the sleeve 19, and the oil throwing pan 8 on the shaft 3. Adopt simple and simple centrifugal pump to pump air on the front nut 1, to cool DC motor 18 (as attached Figure 6 As shown), two symmetrical oblique holes are centrifugal pumps, which naturally saves a more complicated cooling system. The centrifugal compressor rotor 2 is installed on the shaft 3 and rotates with the shaft 3 at a high speed to pressurize the air. The front casing 4 is installed on the compressor support ring 7, which is not only the engine air inlet, but also the compressor pan cover. One front bearing 5 and one rear bearing 21, the front bearing 5 is installed between the shaft 3 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thrust | aaaaa | aaaaa |

| Thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com