Method for synthesizing methyl isobutyl ketone/methyl isobutyl alcohol

A technology of methyl isobutyl alcohol and methyl isobutyl ketone, applied in the field of synthesizing methyl isobutyl ketone/methyl isobutyl alcohol, can solve high production cost, short production process and low production cost and other problems, to achieve the effect of low production cost, simple process and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

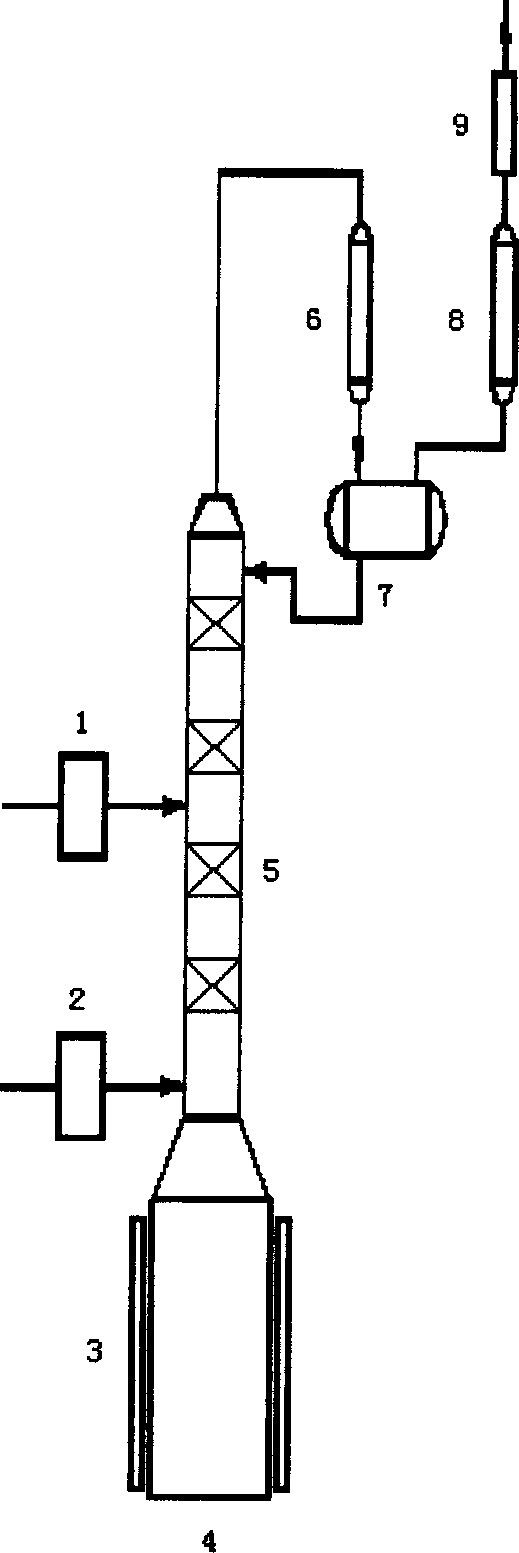

[0024] The specifications of the catalytic distillation tower are: the tower column is 25mm in diameter, the column length is 1200mm, the volume of the tower kettle is 800ml, and the whole tower body is made of stainless steel. The catalyst loading is divided into four sections from top to bottom, the first three sections are Pd / resin catalysts; the latter section is Pd / α-Al 2 o 3 catalyst. Specifically: 1. get 240ml of Pd / resin catalyst, divide into three sections (each section 80ml) and pack in the tower column of catalytic distillation tower. ②Take 80ml Pd / α-Al 2 o 3 The catalyst is loaded into the bottom section of the column of the catalytic distillation tower. Acetone and hydrogen undergo condensation and hydrogenation reactions in the first three stages of catalyst bed to generate MIBK; then MIBK flows into the fourth stage of catalyst bed, where part of MIBK undergoes further hydrogenation reaction to generate MIBC. The raw material hydrogen enters from the bottom...

Embodiment 6-9

[0031]The catalytic distillation tower used in the experiment, the catalyst loading amount, and the loading method are exactly the same as in Example 1. The difference is that in the experiment, a certain amount of acetone was added to the tower kettle at one time, hydrogen gas was continuously introduced, and the temperature was raised by using the tower kettle electric furnace. After the tower top and tower kettle reached the specified temperature, the temperature was kept constant for a certain period of time. After that, the operation was stopped, and the reaction liquid sample was taken for analysis. The details of the reaction conditions and results are shown in Table 2.

[0032] Example

Embodiment 10

[0034] The catalytic distillation tower used in the experiment, the catalyst loading amount, and the loading method are exactly the same as in Example 1. Specifically: ①Pd / resin catalyst is MK-2; ②Pd / α-Al 2 o 3 The catalyst is MC-2. Hydrogen and acetone are continuously fed, the ratio of hydrogen to acetone is 500 (v), and the space velocity of acetone feed is 1.5h -1 , the reaction pressure is 0.7Mpa, under this condition, a 500h stability experiment was carried out, and the results are shown in Table 3.

[0035] During continuous operation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com