Fryer

A frying pan and oil tank technology, which is applied to utensils for frying things in oil, utensils for boiling water, cooking utensils, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

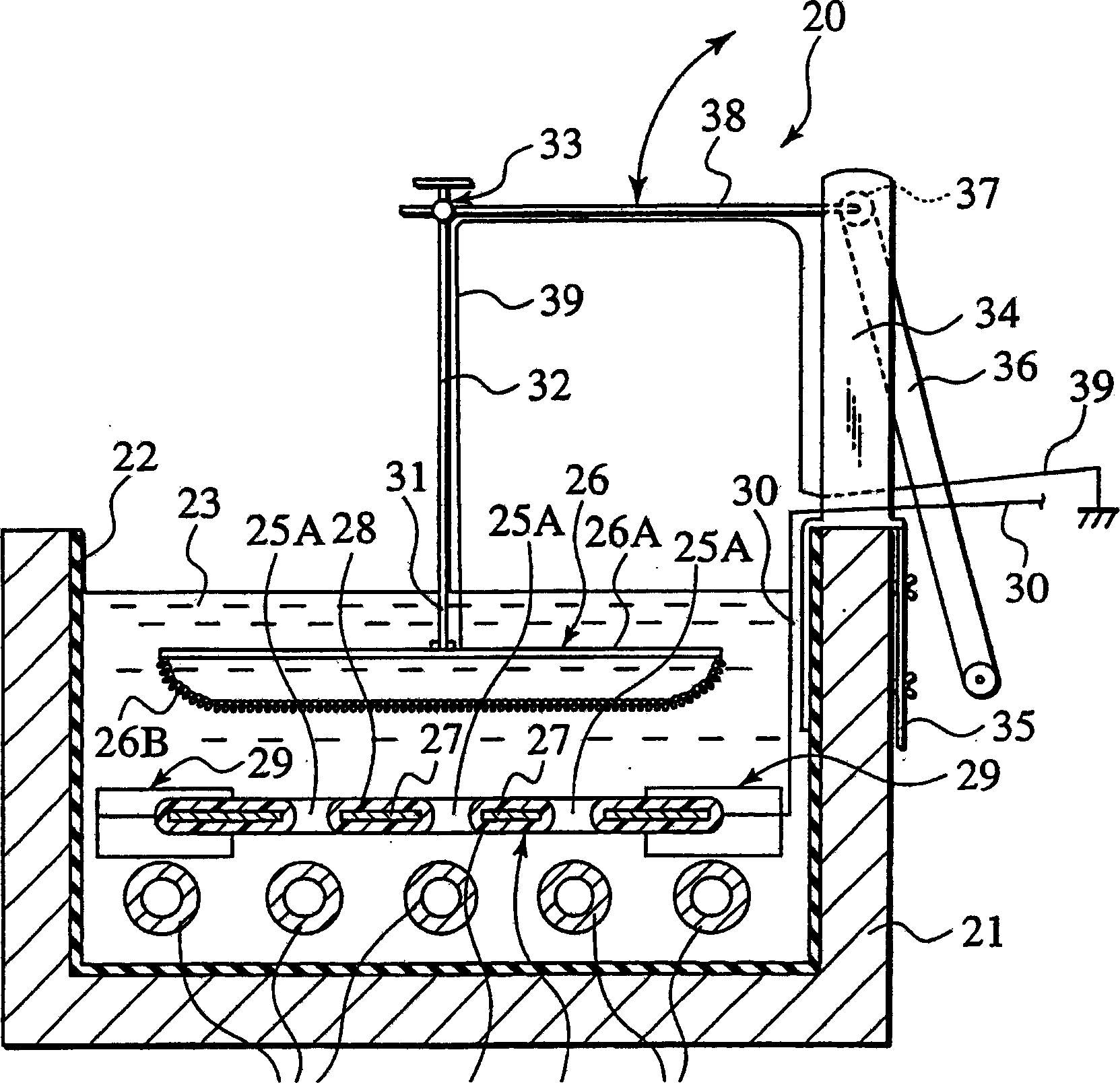

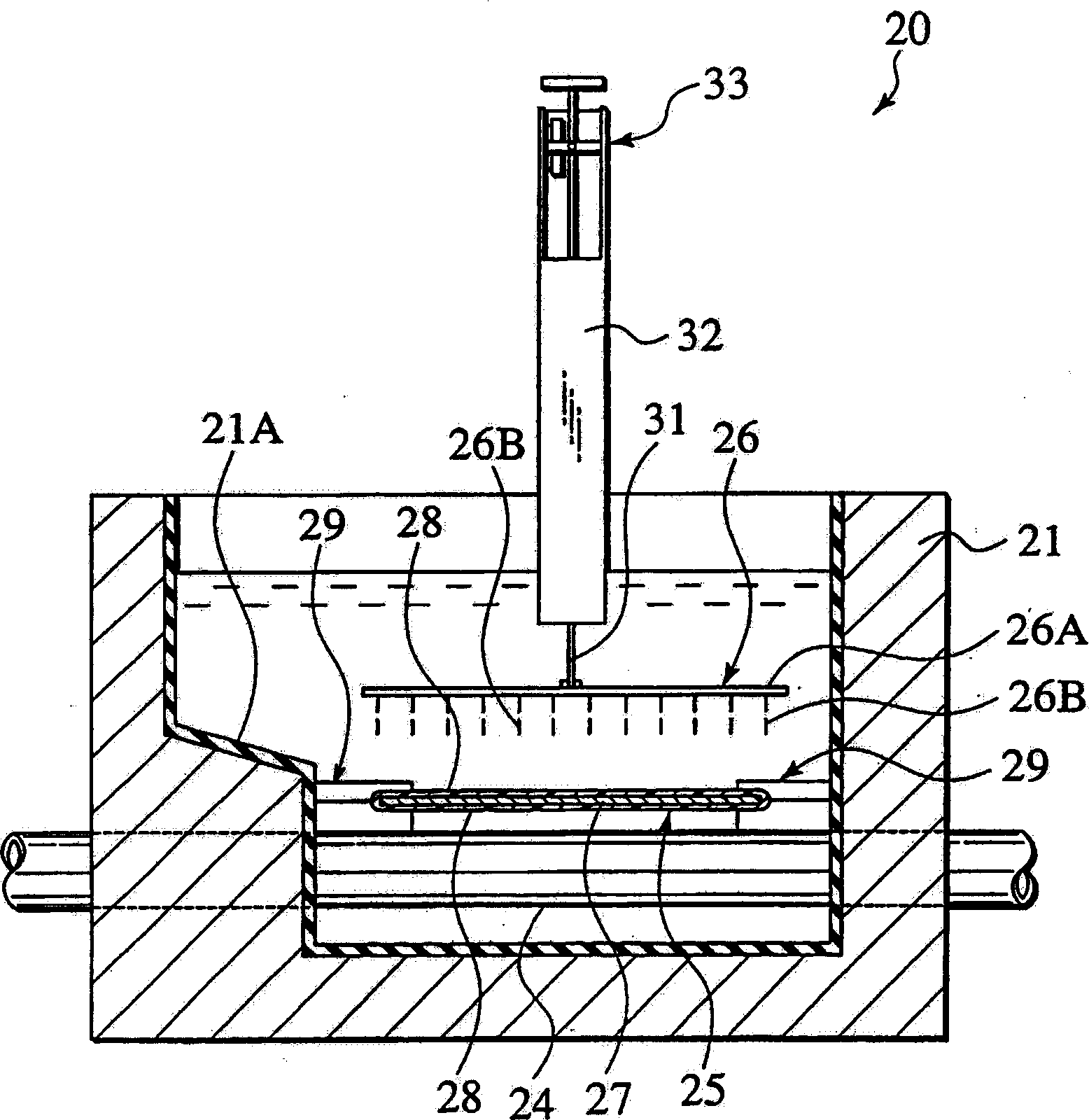

[0046] Figure 2 ~ Figure 6 Shown is a first embodiment of a fryer according to the invention. The first embodiment is an example in which the present invention is applied to a gap type fryer. figure 2 It is a sectional view of fryer 20 seen from the side ( Image 6 II-II sectional view); image 3 It is a cross-sectional view seen from the front ( Image 6 III-III sectional view); Figure 4 is a perspective view of the ground plate 26; Figure 5 It is a plan view showing the state where the electrode plate 25 is arranged in the oil tank 21; Image 6 It is a plan view of fryer 20.

[0047] The deep fryer 20 of this first embodiment, as figure 2 and image 3 As shown, the electric field shielding layer 22 formed substantially by the oil tank 21 , covering the entire inner surface of the oil tank 21 , several heating tubes 24 for heating the frying oil 23 contained in the oil tank 21 , and the heating tubes 24 are arranged. The electrode device 25 directly above is con...

no. 2 example

[0060] Figure 7 ~ Figure 10 Shown is a second embodiment of the deep fryer of the present invention. The fryer of the second embodiment is also gap type. Figure 7 It is a sectional view of fryer 40 seen from the side ( Figure 10 XII-XII sectional view), Figure 8 is a cross-sectional view seen from the front ( Figure 10 XIII-XIII sectional view), Figure 9 is a plan view of the state where the ground plate is arranged, Figure 10 It is a plan view showing the state where the electrode plate is arranged in the oil tank.

[0061] The deep fryer 40 of this second embodiment, as Figure 7 and Figure 10 As shown, the electric field shielding layer 42 formed substantially by the oil tank 41, covering the entire inside of the oil tank 41, several heating tubes 44 for heating the cooking oil 43 contained in the oil tank 41, are arranged directly above the heating tube 44. The ground plate 45 is formed by an electrode device 46 that is disposed opposite to the ground plate...

no. 3 example

[0073] Figure 11 and Figure 12 Shown is the third embodiment of the deep fryer of the present invention. In the fryer 60 of the third embodiment, the electric field shielding layer 62 is formed on the entire inner surface of the oil tank 61 . In addition, the heating pipe 63 disposed in the oil groove 61 is arranged to be introduced into the oil groove 61 from one side of the side wall, and is bent into a substantially Z shape at the bottom of the oil groove 61 to lead to the outside from the other side of the side wall. form. Therefore, in the third embodiment, it is not necessary for the heating pipe 63 to pass through the oil groove 61 .

[0074] Also, in the third embodiment, the electrode device 64 is provided to be freely raised and lowered by being driven to move up and down together with the raising and lowering frame 65 . In addition, in the fryer 60 of the third embodiment, a ground plate not shown may be arranged below the electrode device 64 or may be arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com