Method for back-extracting and separating radioactive element from organic phase by using water soluble oxaamide

A technology of radioactive elements and oxaamides, which is applied in the field of oxaamides, can solve the problems of excessive secondary waste and poor decomposition of stripping products, and achieve the effects of easy decomposition, convenient industrial scale production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

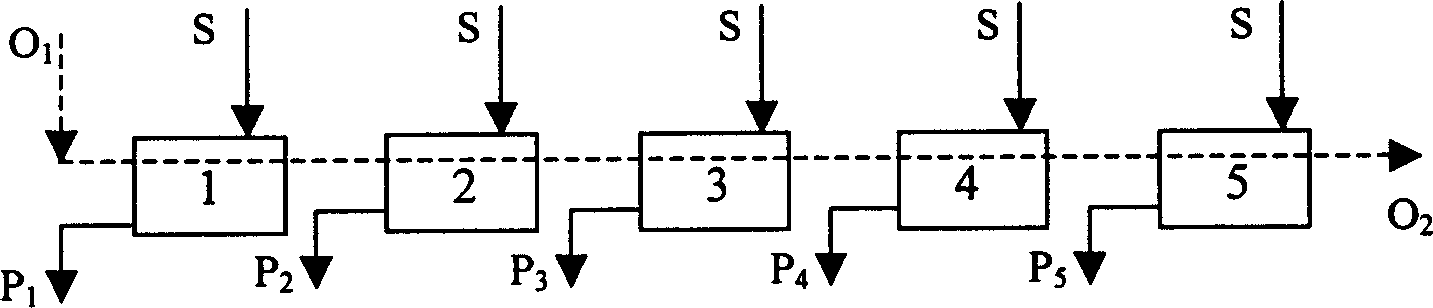

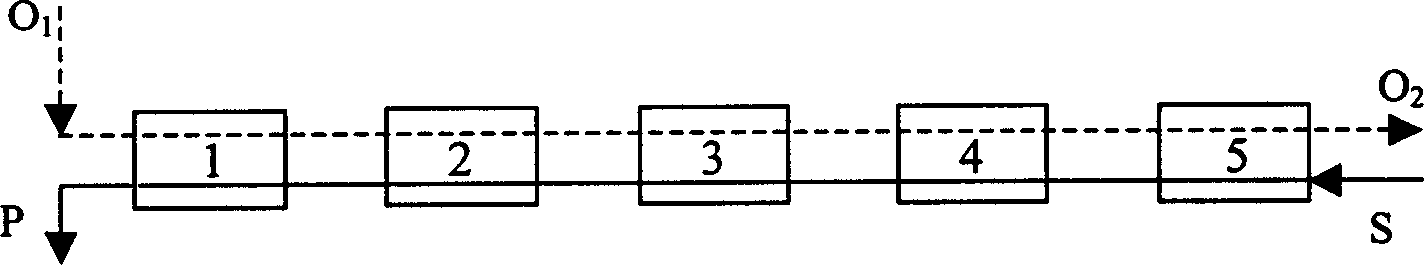

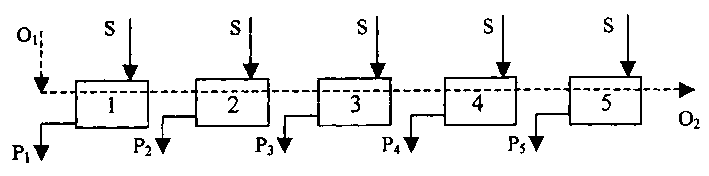

[0024] according to figure 1 Shown stripping flow process carries out cross-flow stripping test, and concrete parameter is as follows: O 1 : Organic phase containing uranium, transuranic elements and lanthanides (30% v / v TRPO-kerosene solution) S: Containing 0.5mol / L water-soluble N,N-dialkyl-3-oxa-pentane mono Amide solution, the acidity is 0.1-0.8mol / L HNO 3 P, P 1 , P 2 , P 3 , P 4 , P 5 : Aqueous stripped product stream containing transuranic elements and lanthanides. o 2 : Organic reverse extraction containing only uranium Number of stages: 5; Flow ratio: organic phase / aqueous phase = 1:1 Stripping time: 30 minutes; Stripping temperature: 25°C Stripping rate of transuranic elements and lanthanides More than 99%, the stripping rate of uranium is less than 0.1%.

Embodiment 2

[0026] according to figure 1 The process carries out cross-flow stripping test, wherein: S: water-soluble N, N, N', N'-tetraalkyl-3-oxa-glutaramide solution containing 0.1mol / L, acidity is 1.5-2.0mol / L HNO 3 All the other parameters are the same as in Example 1. After five stages of cross-flow stripping, the stripping rate of transuranium elements and lanthanide elements can reach more than 99%, and the stripping rate of uranium is less than 0.1%.

Embodiment 3

[0028] according to figure 1 Flow process carries out cross-flow stripping test, wherein: O 1 All the other parameters of the organic phase (30%TBP-kerosene solution) containing uranium and plutonium are with embodiment 1, through 5 stages of cross-flow stripping, the stripping rate of plutonium is greater than 99.9%, and the stripping rate of uranium is less than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com