Microwave dielectric procelain composition and dielectric resonator

A technology of dielectrics and compositions, applied in resonators, waveguide devices, ceramics, etc., can solve problems such as Qu reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

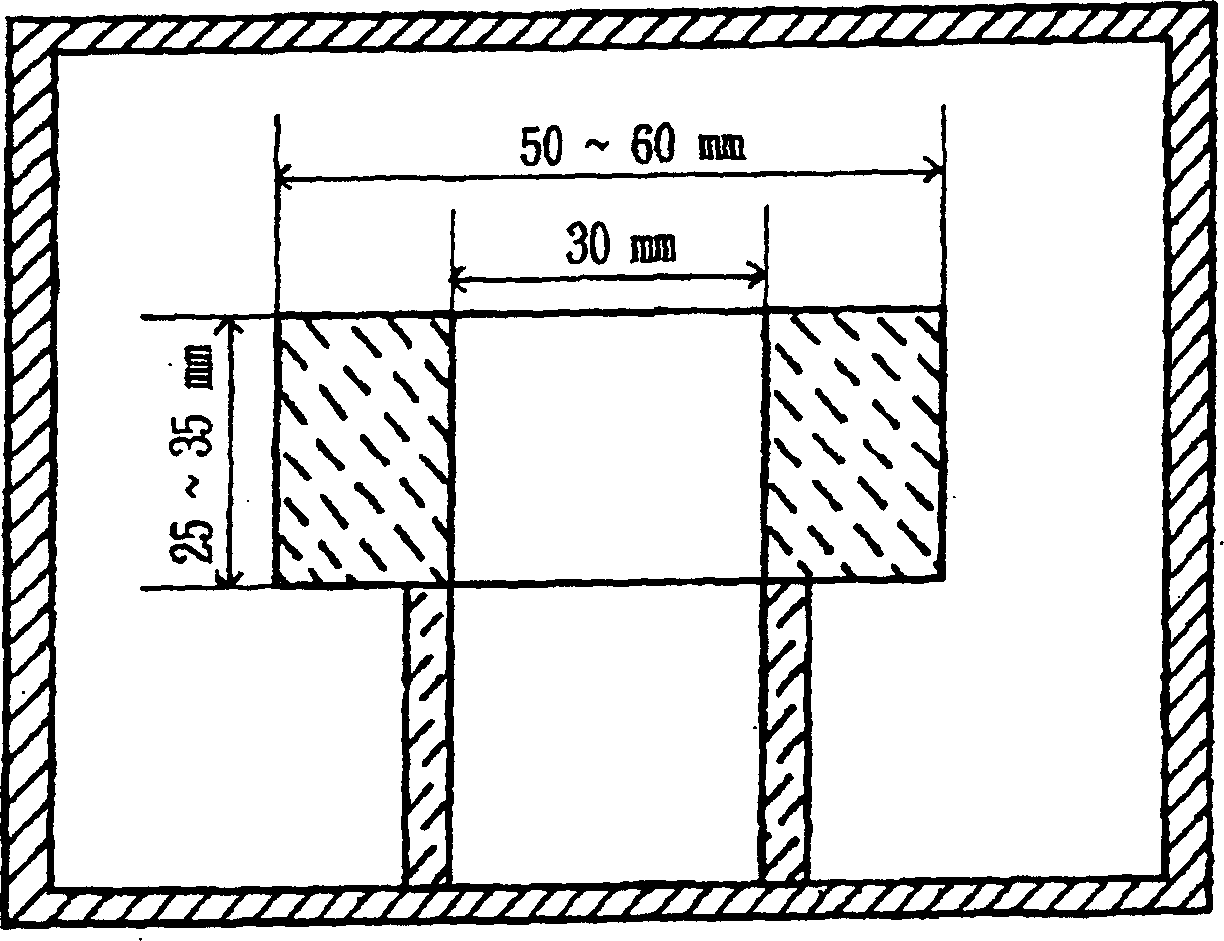

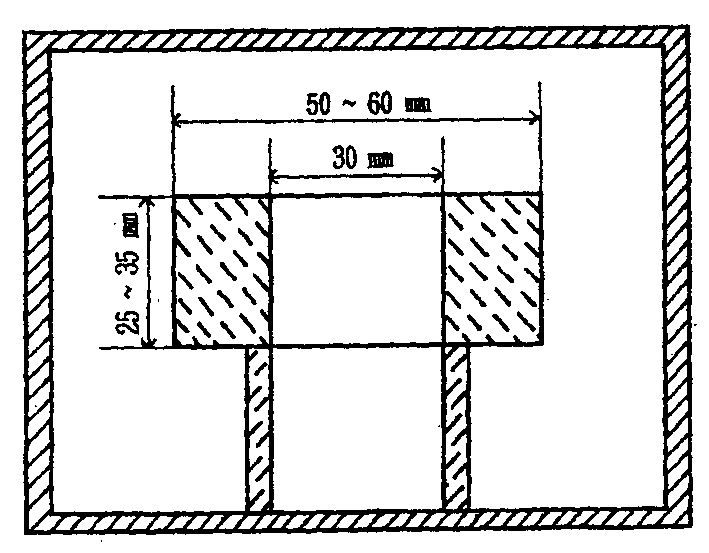

Image

Examples

Embodiment 1

[0031] (1) Preparation of test piece

[0032] According to the ratio shown in Table 1, TiO 2 Powder (purity: 99.99%), CaCO 3 Powder (purity: 99.9%), La 2 o 3 Powder (purity: 99.9%), Nd 2 o 3 Powder (purity: 99.9%), Sm 2 o 3 Powder (purity: 99.9%), Al 2 o 3 powder (purity: 99.95%), and Ta 2 o 5 Powder (purity: 99.2%) was mixed. Then, dry mixing (20 to 30 minutes) was performed in a mixer, and then crushing was performed once. Then, provisional sintering is performed at 1100 to 1300° C. for 2 hours in the air atmosphere. Then, an organic binder and water were added to the temporarily sintered powder, and pulverization was carried out at 90 rpm for 10 to 15 hours using zirconia balls with a diameter of 10 mm. Then, granulate by vacuum freeze-drying (vacuum degree is about 0.4 Torr, freezing temperature is -20~-40°C, drying temperature is 40~50°C, vacuum drying time is about 20 hours), and the raw material after granulation is used , with 1 ton / cm 2 stamping, formin...

Embodiment 2

[0042] (1) Production of test piece and dielectric resonator

[0043] CaCO 3 Powder (purity: 99.9%), TiO 2 Powder (purity: 99.95%), Al 2 o 3 powder (purity: 99.95%), Ln oxide powder (purity: 99.95%) described in Table 2 and Table 3, Na 2 CO 3 Powder (purity: 99.5%), Ta 2 o 5 powder (purity: 99.95%), and MnO 2 Powder (purity: 99.9%) is the raw material powder, so that the molar ratio of x, Ln and Na 2 O. Ta 2 o 5 and MnO 2 The content of the mixture is formulated as shown in Table 2 and Table 3, and after dry mixing with a stirrer for 20 to 30 minutes, primary pulverization is performed by a vibrating mill. Alumina balls were used as the grinding balls, and the pulverization time was set to 4 hours.

[0044] In the air atmosphere, at 1100-1300 ℃, temporarily sinter the obtained powder for 2 hours, add an appropriate amount of organic binder and water to the temporarily sintered powder, and carry out 10-15 hours of secondary sintering with a drum sieve pulverizer. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com